Trapezoidal thread form having wear indicator and high pressure connection fitting comprising same

A wear indicator, trapezoidal thread technology, applied in threaded connections, connecting components, threaded fasteners, etc., can solve problems such as impossible to detect wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

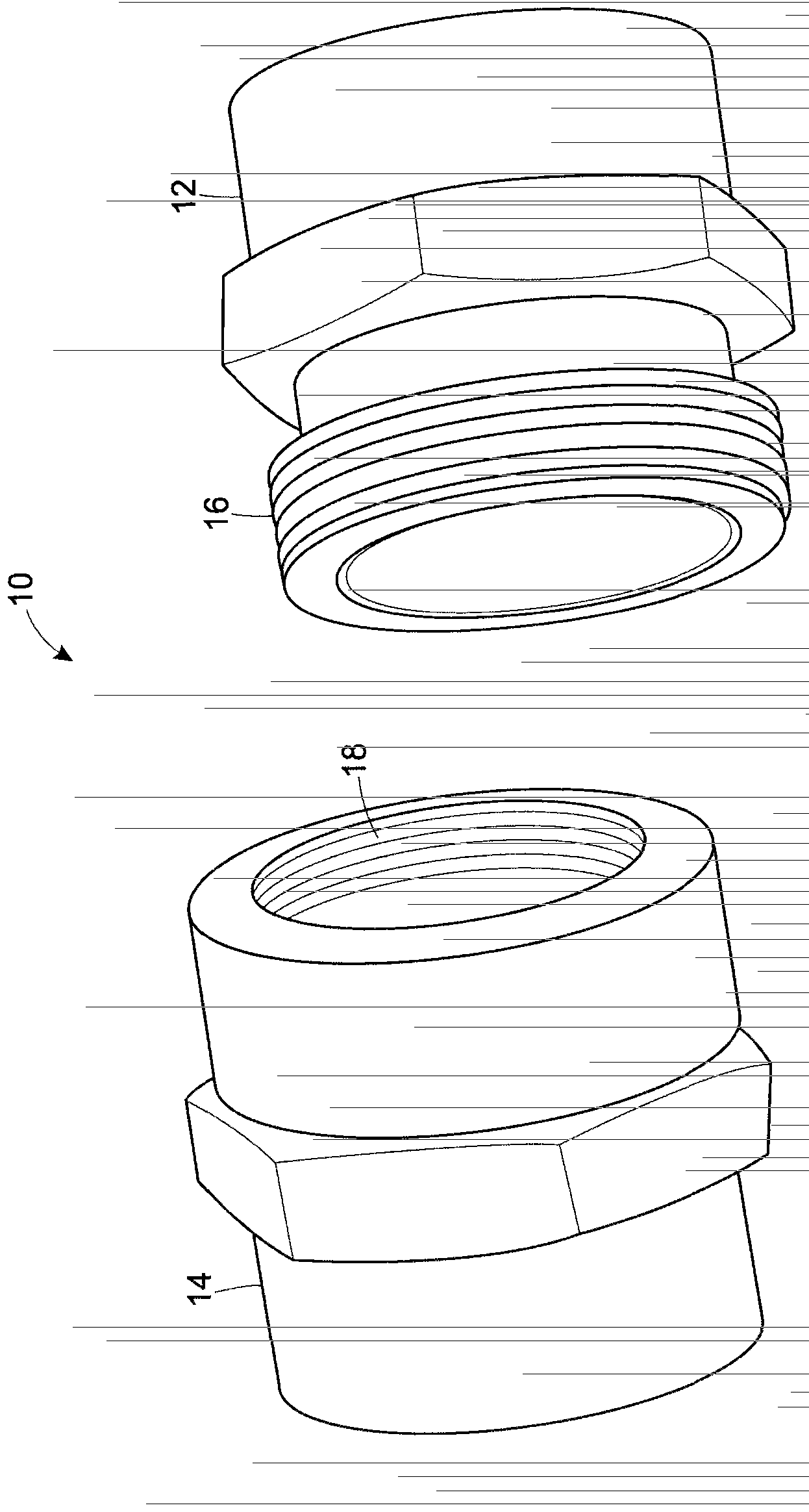

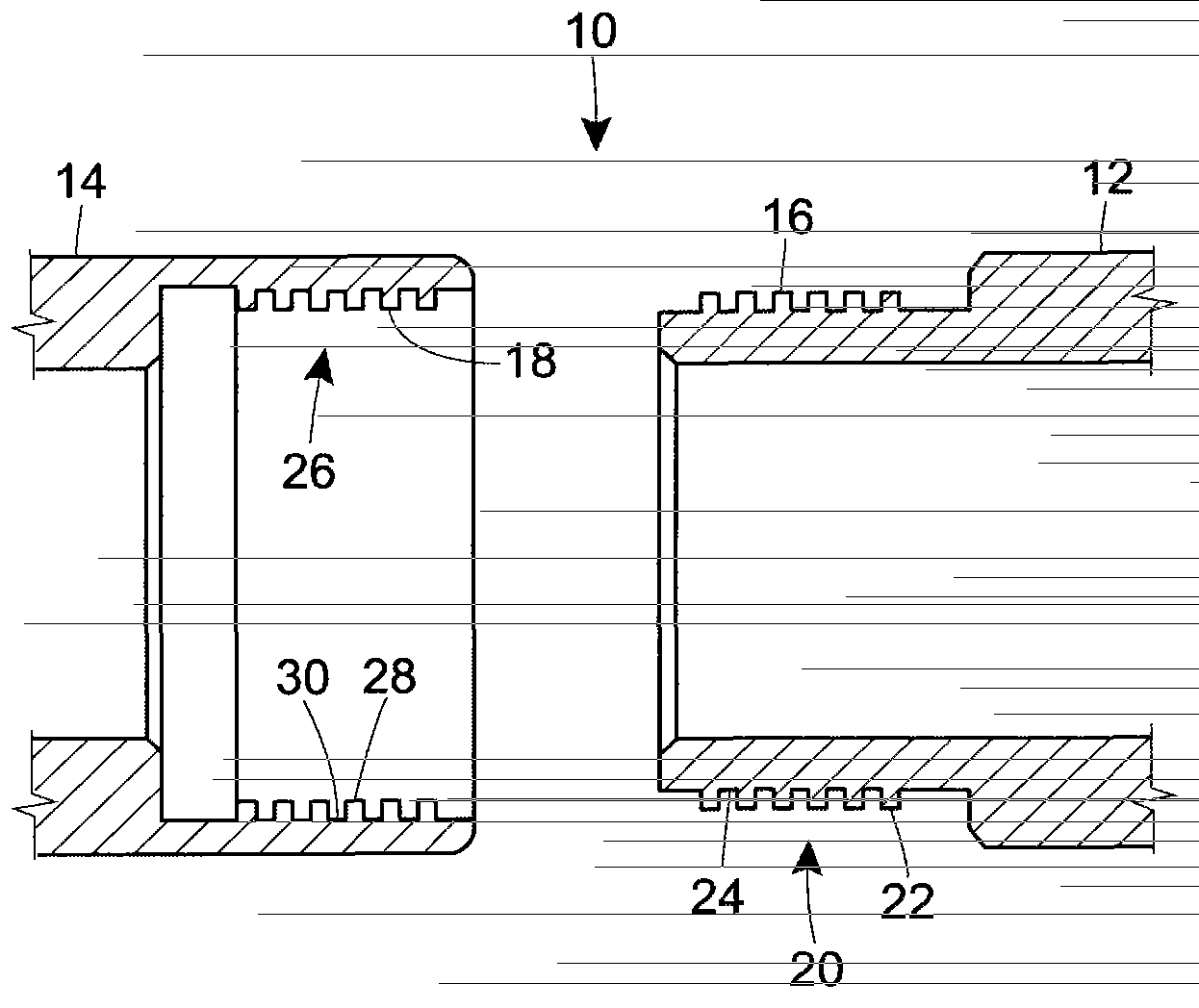

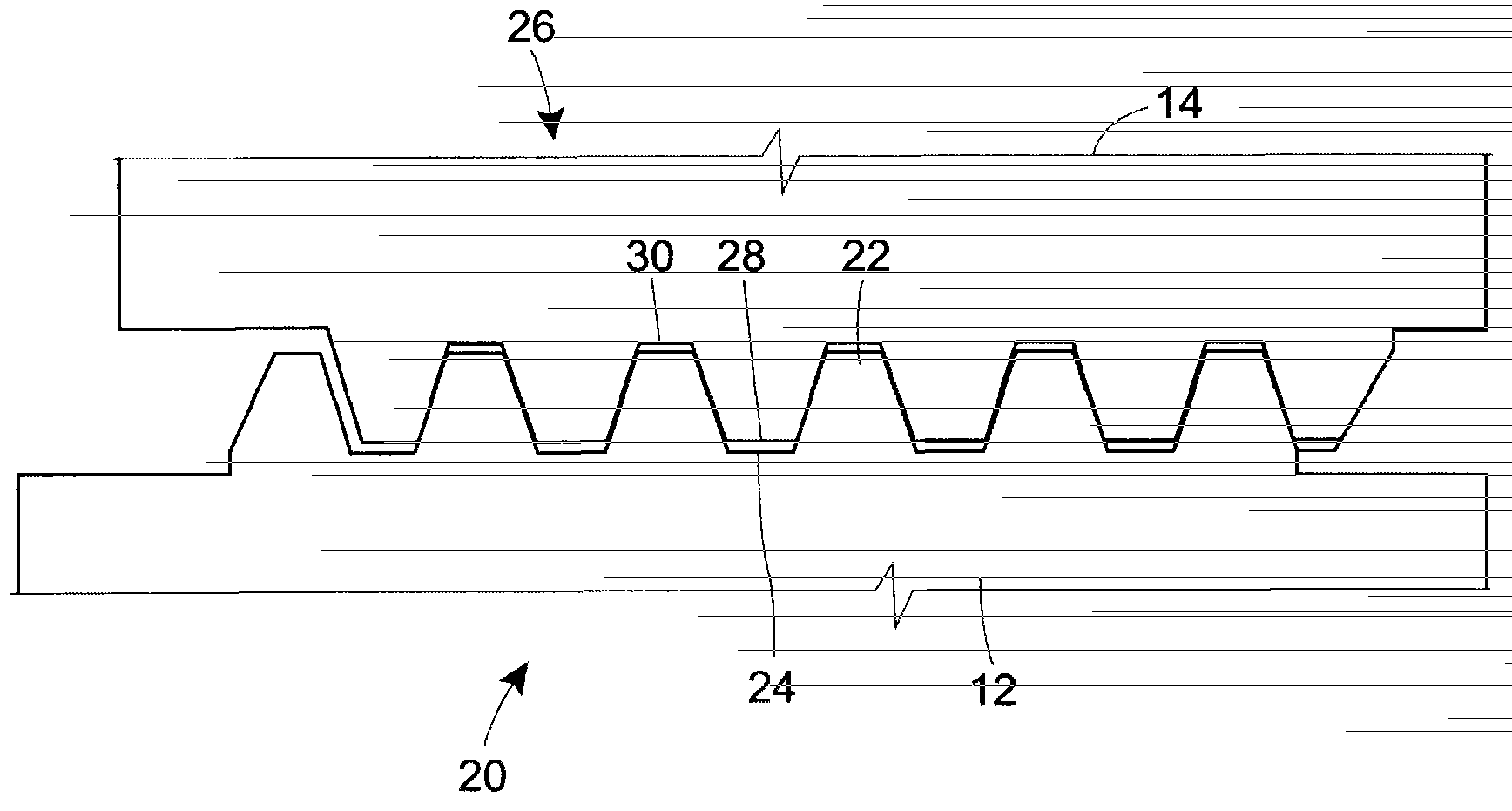

[0020] This article describes various types of trapezoidal threads that include thread wear indicators. However, in other embodiments, the thread wear indicators described herein can be applied to other threaded connections, such as square and V-threads.

[0021] Thread galling in threaded connections can be an important safety concern. Overuse, abuse, and lack of adequate inspection and inspection techniques have led to an incident where premature wear of trapezoidal thread profiles, such as inch trapezoidal thread profiles, has resulted in undesired separation of fittings resulting in accidents, property damage and die. Acme threads are fairly common in the liquefied propane (LP) gas industry for fuel delivery and have recently come under scrutiny. To reduce the likelihood of failure, some refineries require that fuel transfer couplings use refinery hoses that are periodically inspected by the refinery. However, inspection methods are usually limited by natural conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com