Method for blocking adhesive in mixed pressing process of printed circuit board plate

A technology for circuit boards and board parts, which is applied in the field of glue resistance during the mixed pressure process of circuit board parts, and can solve problems such as residual glue flow on the surface of circuit board parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

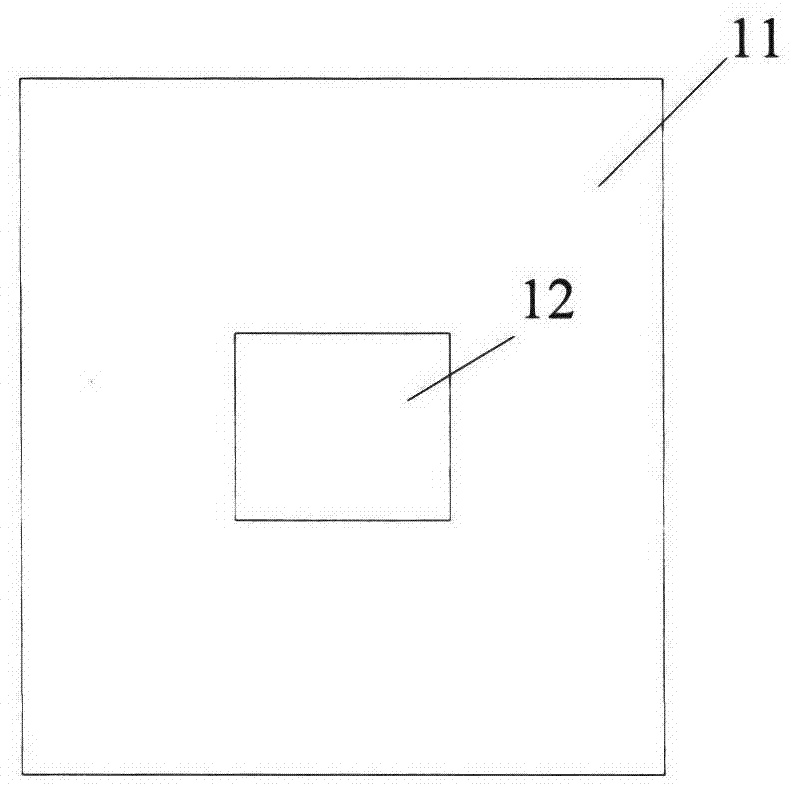

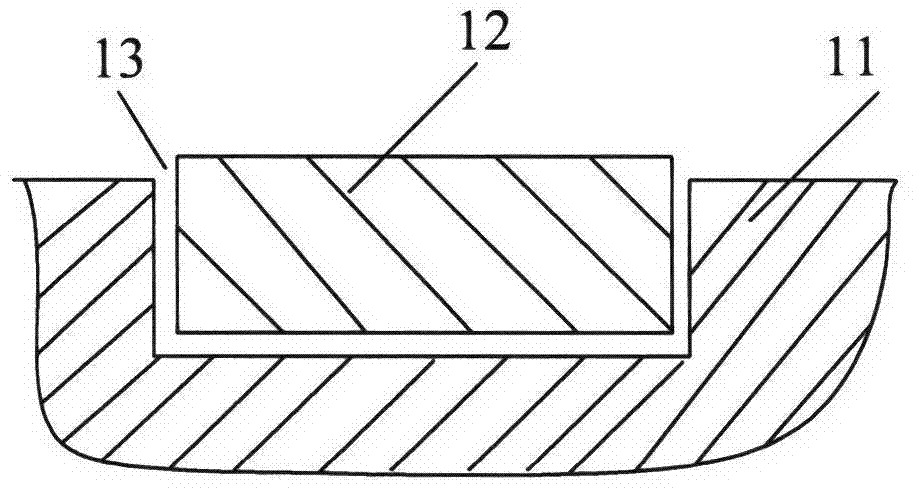

[0015] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments. see Figure 4 The flowchart shown includes the following steps:

[0016] S11: making grooves for placing mixed pressure materials on the circuit board;

[0017] The circuit board components include a dielectric layer and a circuit board, and the dielectric layer is used for bonding two adjacent circuit boards. According to the thickness of the mixed-pressed material, grooves for placing the mixed-pressed material are processed on the corresponding layers of circuit boards or dielectric layers.

[0018] Mixed pressure materials include heat dissipation metals or components, etc.

[0019] S12: Fix the circuit boards of each layer together, and place the mixed pressure material in the groove;

[0020] Various layers of circuit boards can be fixed together by melting glue or riveting.

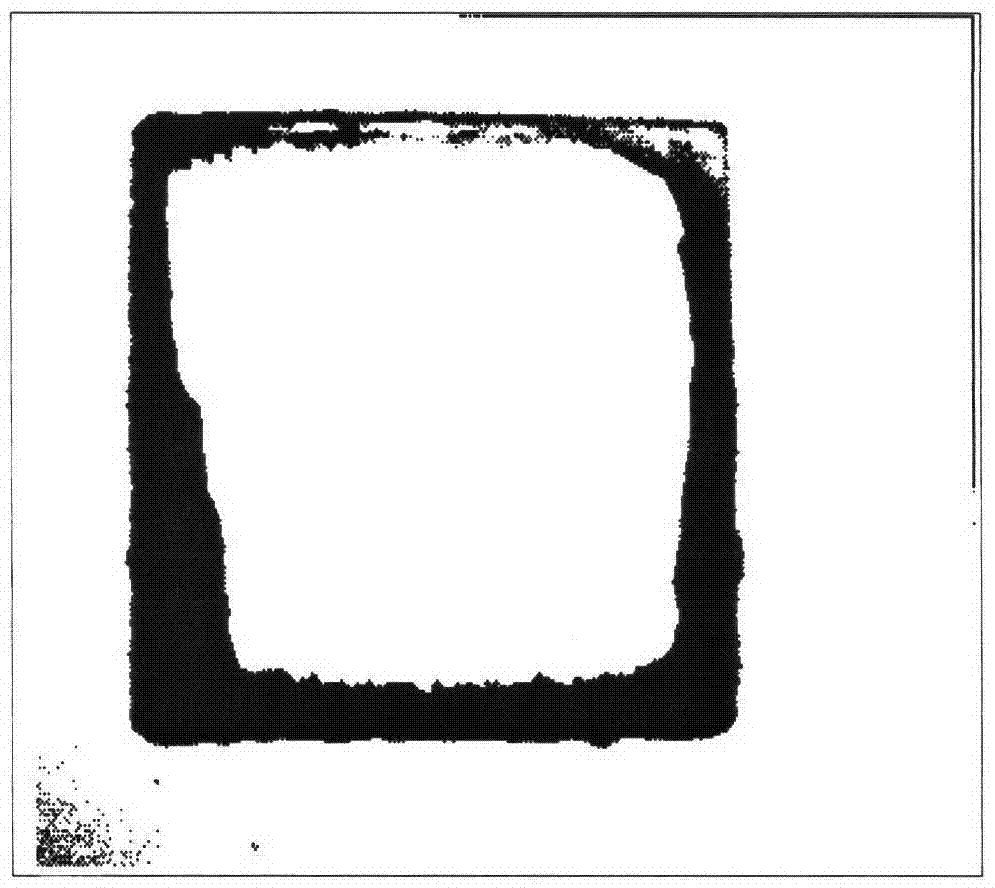

[0021] S13: Pressing after covering the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com