Airflow management system

A technology for managing systems, air flow, applied to electrical components, lawn mowers, cooling/ventilation units, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

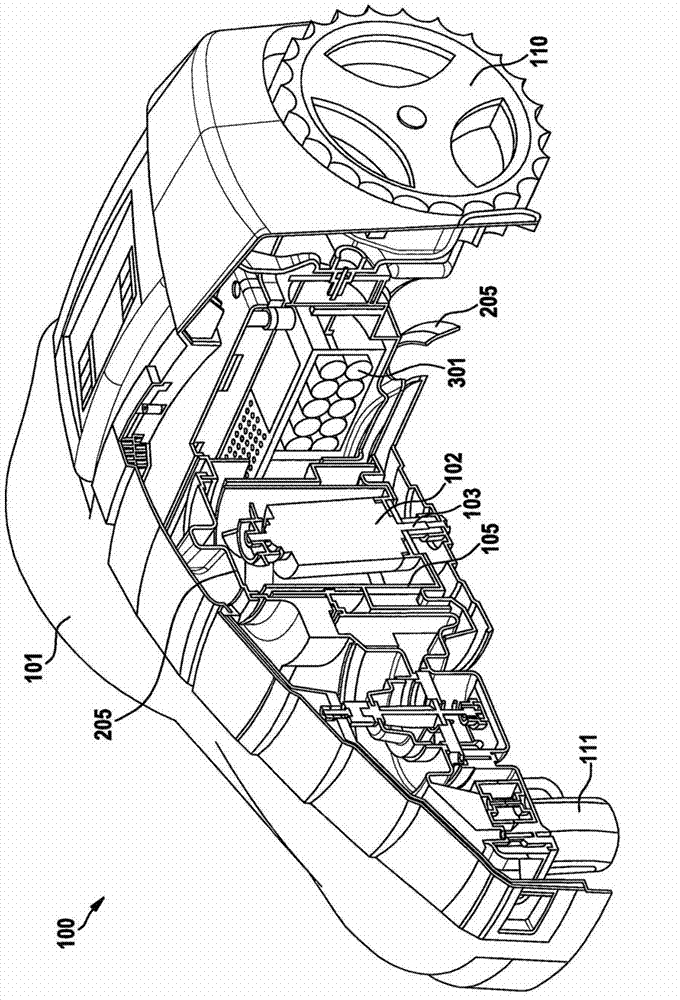

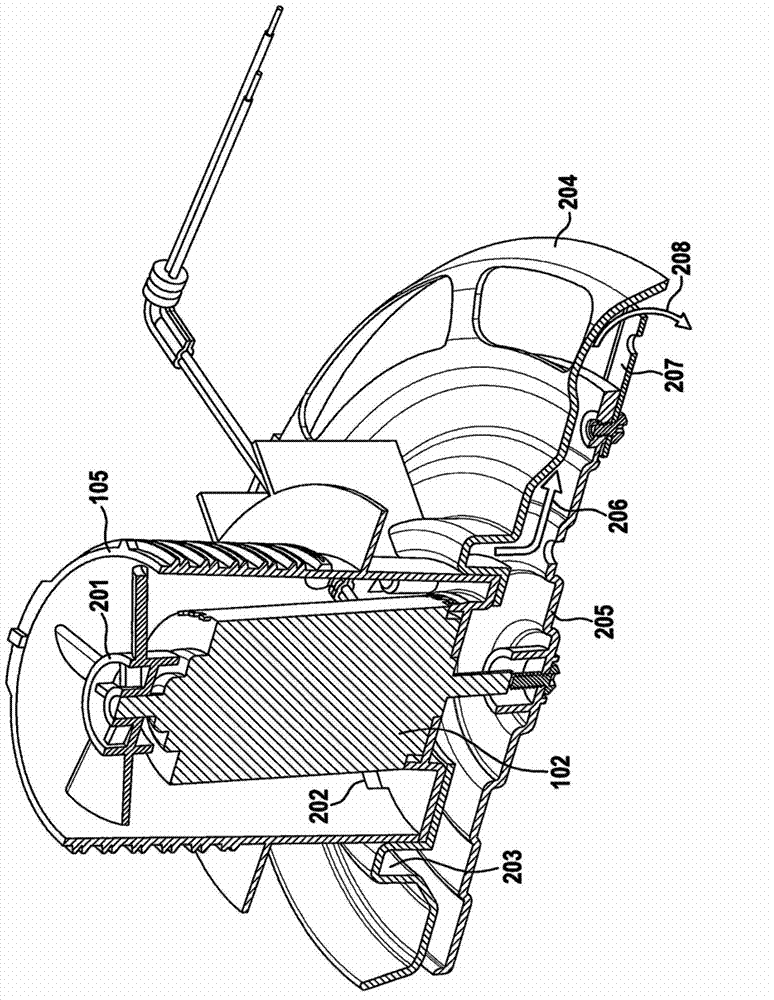

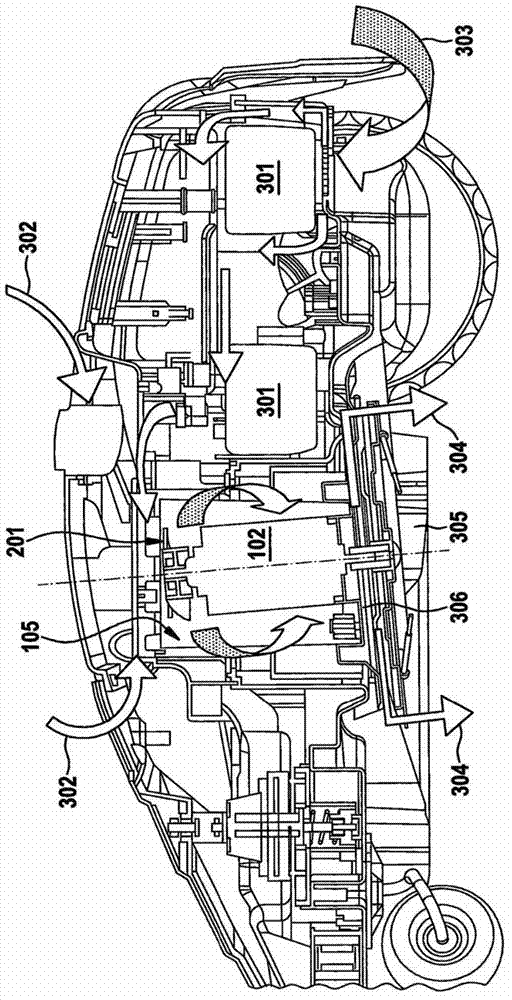

[0024] figure 1 A lawn trimmer 100 is shown having a housing part 101 , a drive motor 102 for driving a shaft 103 for attachment to a cutting disc 205 , and a gear 104 for driving a cooling fan 201 . Housing portion 105 with vents (not shown) houses the motor and cooling fan, and forms part of the underframe of the trimmer, thereby providing protection for other components of the trimmer such as the wheels 110, 111, battery pack 301 and control electronics. Provides a mount point.

[0025] In the illustrated embodiment of the invention, the front section of the trimmer is sufficiently sealed from moisture ingress because there are no components in this section that require cooling. The rear section is vented at selected locations to allow cooling during operation. This will be explained in more detail below. Ventilation is also provided at the top of the trimmer. Vents are located on the underside of the housing to protect the trimmer from the weather. In the described em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com