Radiating device

A technology of a heat dissipation device and a heat dissipation element, which can be used in heating methods, household heating, household heating, etc., and can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

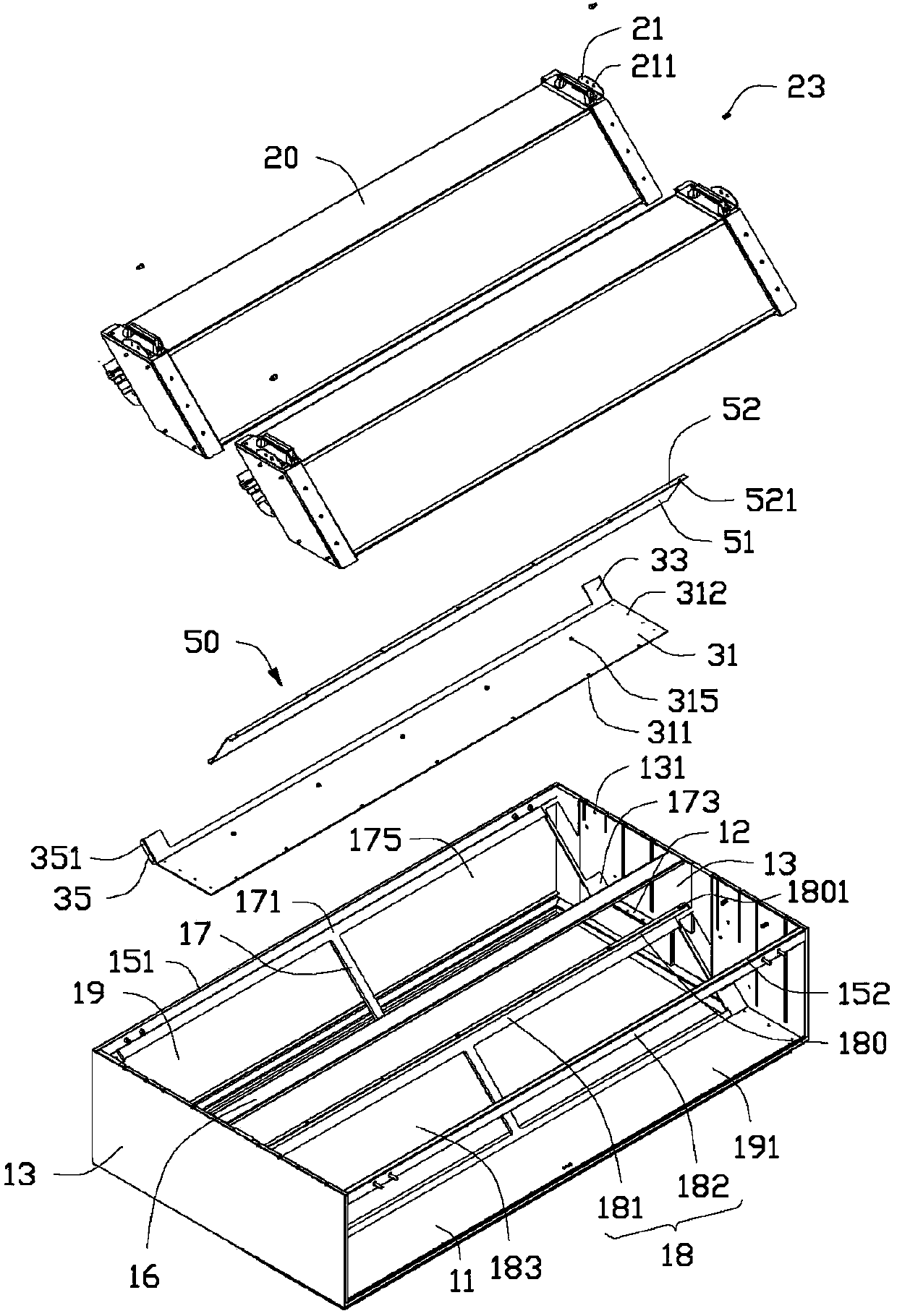

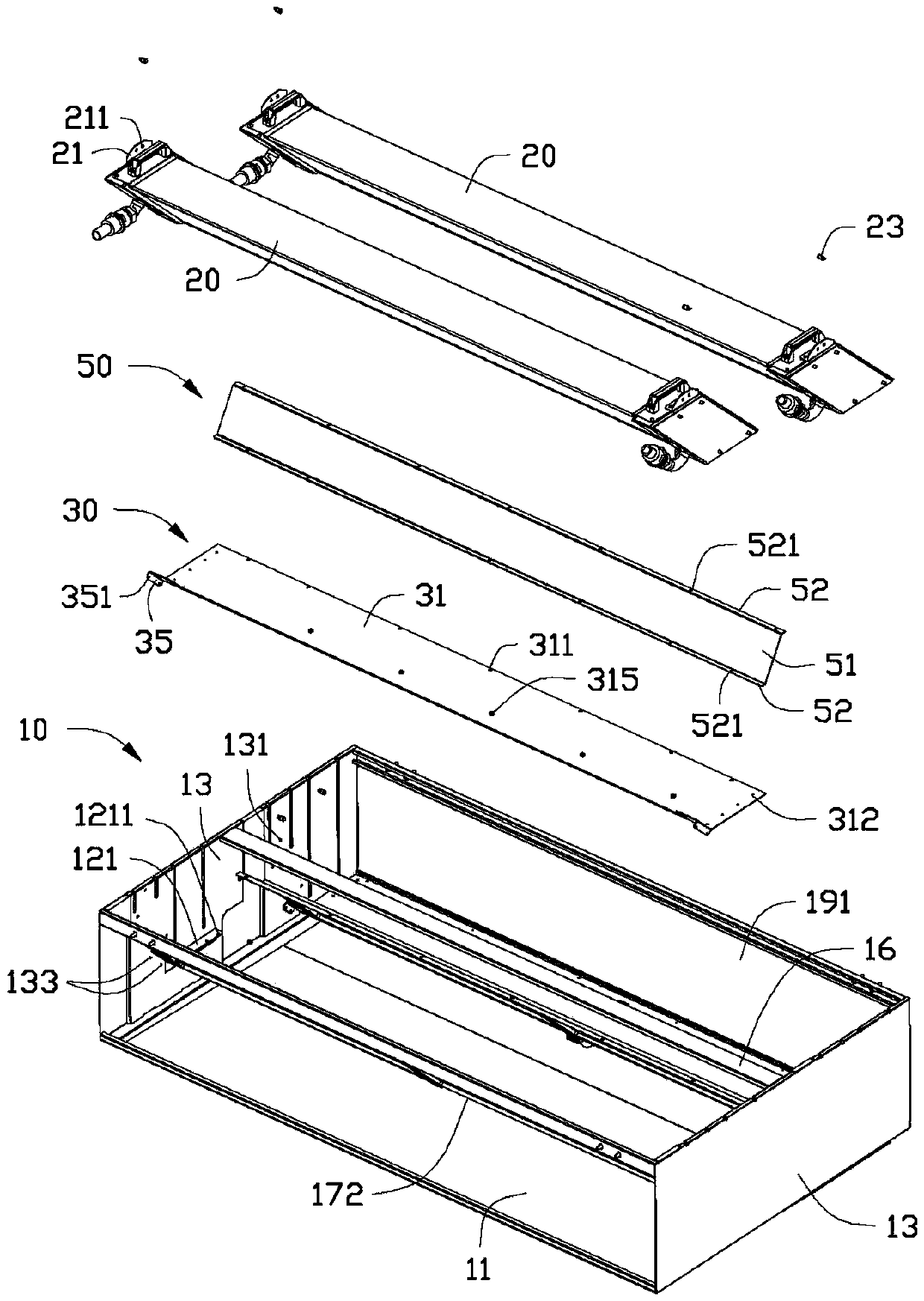

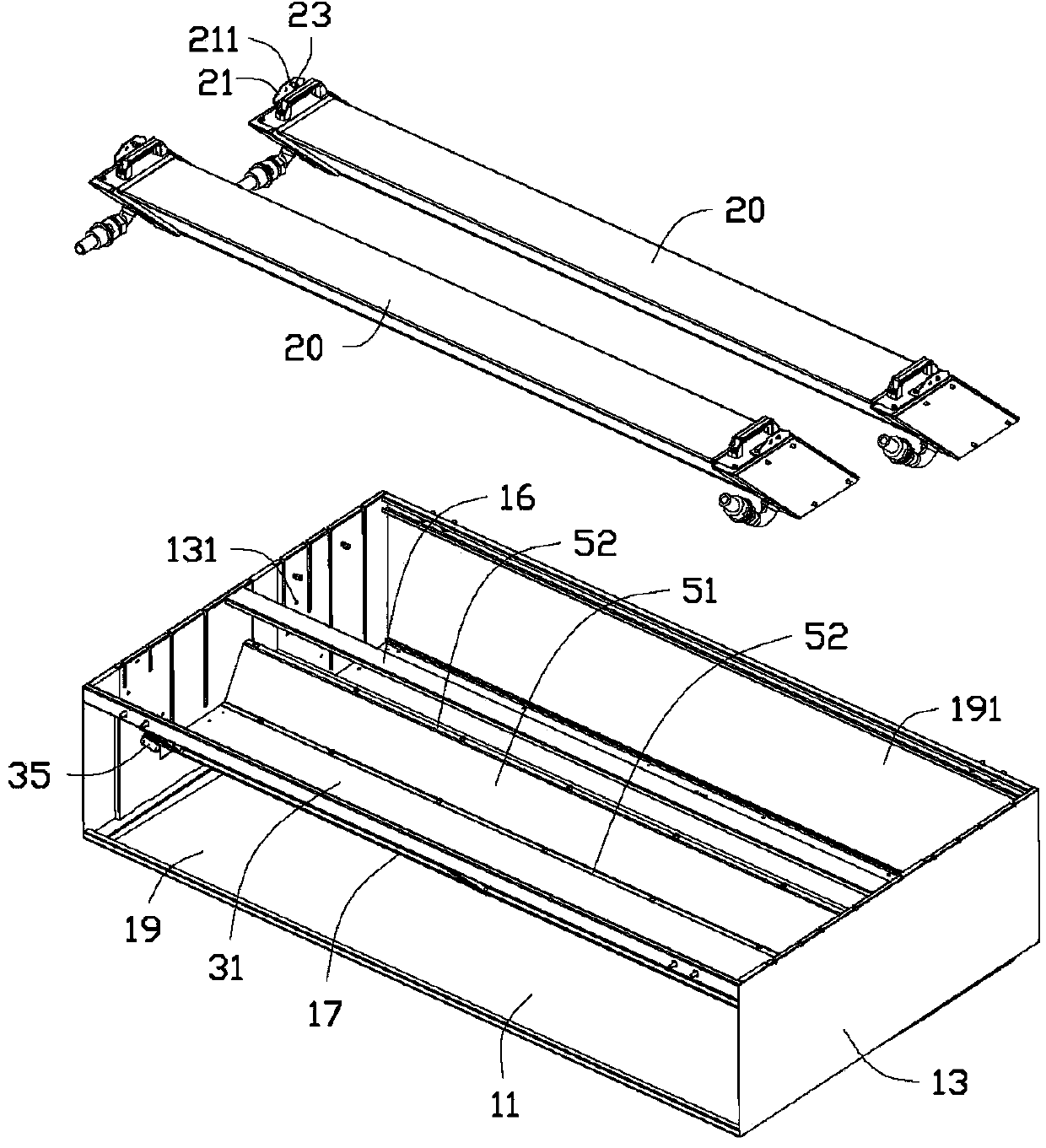

[0024] see figure 1 and figure 2 , In a preferred embodiment of the present invention, a heat dissipation device includes a housing 10 , two heat dissipation elements 20 , a support 30 and a partition 50 .

[0025] The housing 10 includes a bottom plate 11 and two opposite side plates 13 . In one embodiment, the bottom plate 11 is substantially perpendicular to the two side plates 13 . Described bottom plate 11 has certain slope, and offers a drainage hole 112 (such as Image 6 shown). The drain hole 112 is connected to a water outlet pipe (not shown in the figure) for draining the water in the casing 10 . A first beam 151 , a second beam 152 and an operation beam 16 are installed between the two side plates 13 . The first beam 151 and the second beam 152 are connected between side edges of the two side panels 13 that are substantially perpendicular to the bottom panel 11 . In one embodiment, the operating beam 16 is substantially parallel to the bottom plate 11 and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com