Leftover material wrapuping device capable of realizing parallel winding

A technology of winding device and leftover material, which is applied in the direction of thin material processing, transportation and packaging, and delivery of filamentous materials, etc. It can solve the problems of inability to realize recycling, achieve high winding recycling efficiency, and realize the effect of winding density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

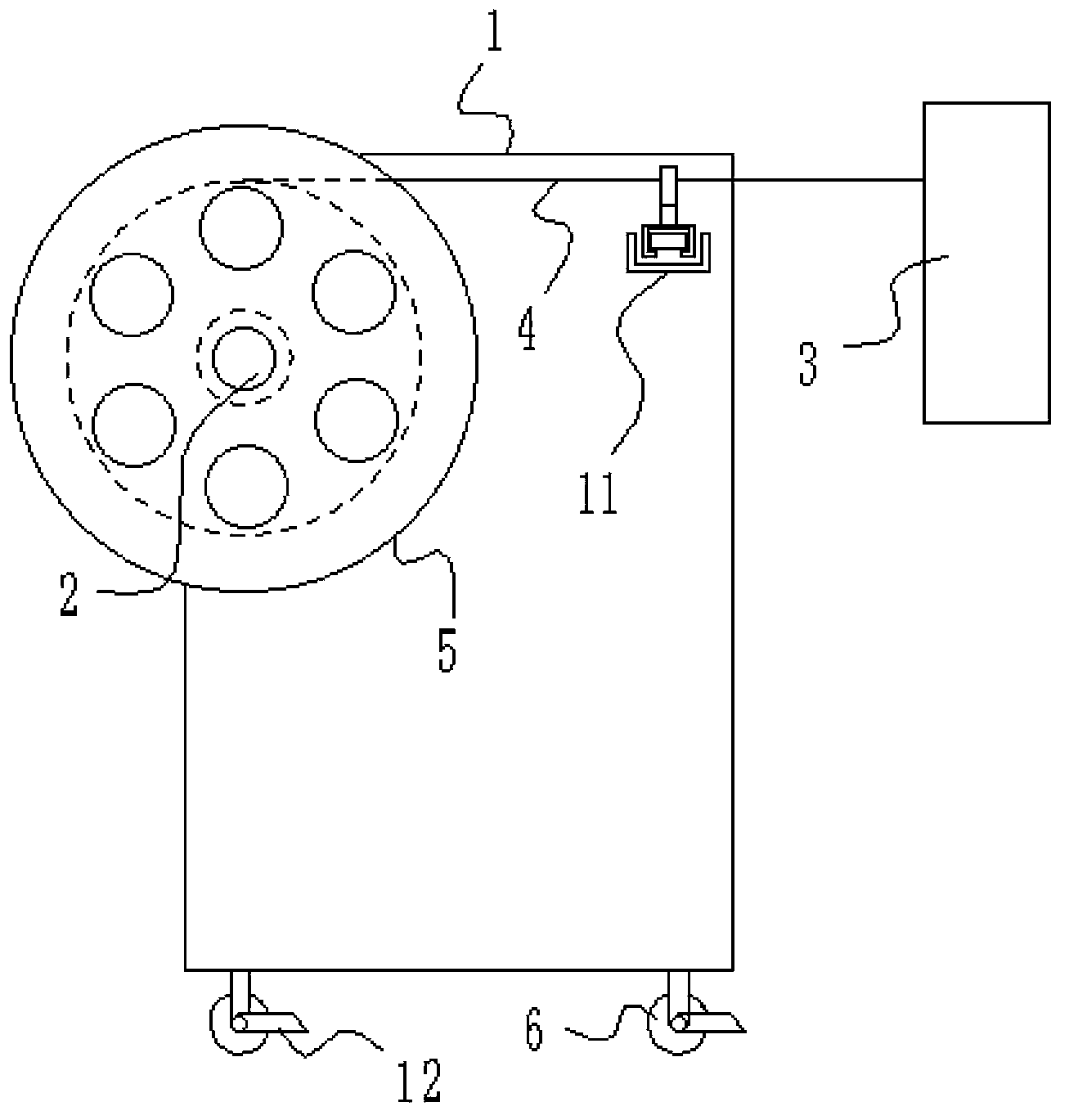

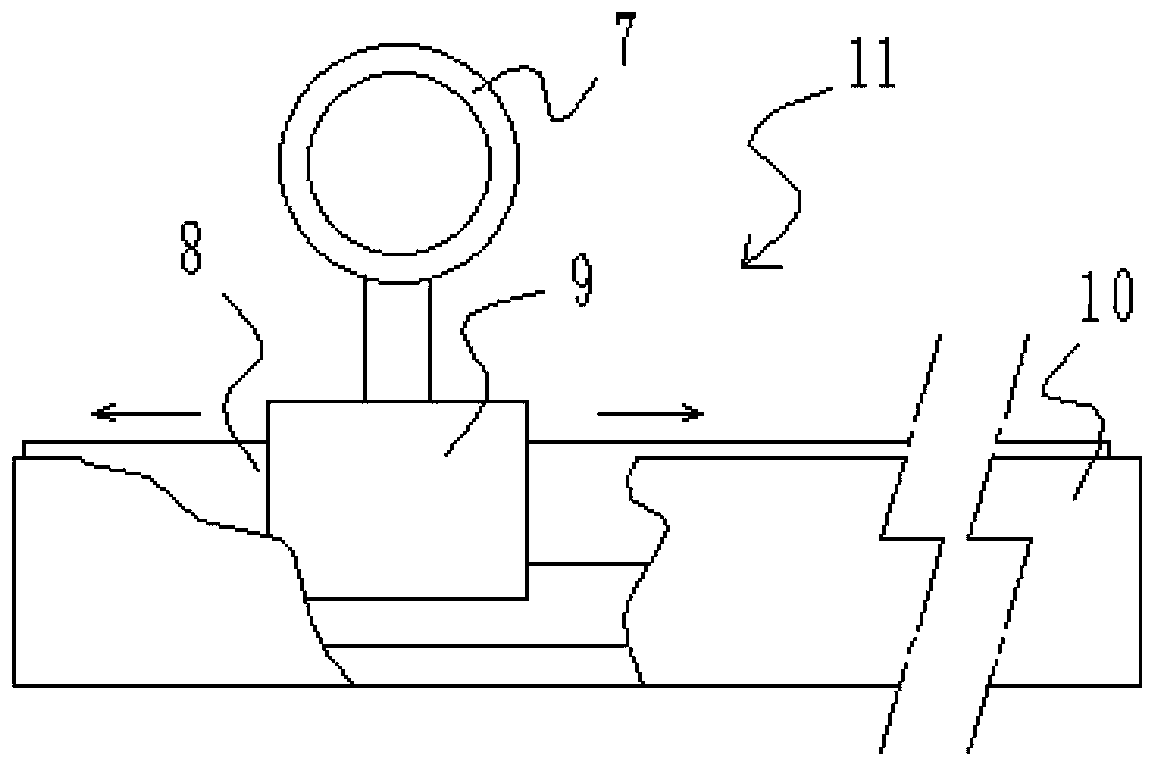

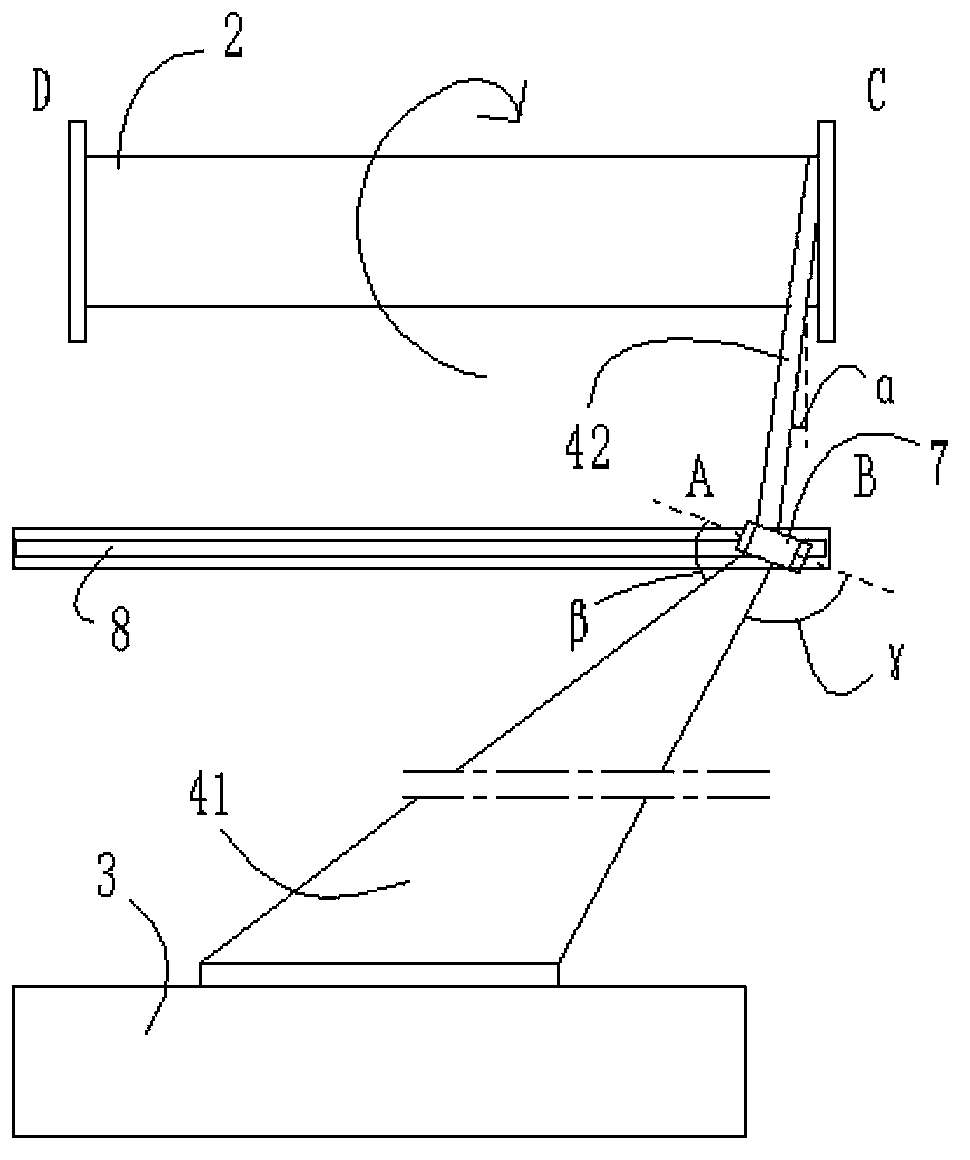

[0029] As a preferred embodiment of the present invention, such as figure 1 with 2 As shown, a leftover material winding device for realizing parallel winding includes a winding mechanism for winding the leftover material 4 and a power mechanism for realizing the operation of the winding mechanism. The passage area is provided with a traction mechanism 11 for reducing the width of the leftover material 4 and realizing its parallel winding in the winding mechanism.

[0030] In the leftover material winding device of the present invention, by adding a traction mechanism 11, the leftover material 4 can be wound in parallel on the winding mechanism. The traction mechanism 11 does not need to provide additional power, which saves a lot of electric energy compared with the traditional reciprocating winding equipment. Under the action o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com