Device for determining boiler flue gas engineering acid dew point

A technology for boiler flue gas and acid dew point, which is applied in the field of devices with a sudden change in heat transfer performance (engineering acid dew point), can solve problems such as difficulty in obtaining dew point accurately, potential safety hazards, strong sealing, etc., and achieve objective and true measurement results. The effect of simplifying the difficulty of building

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

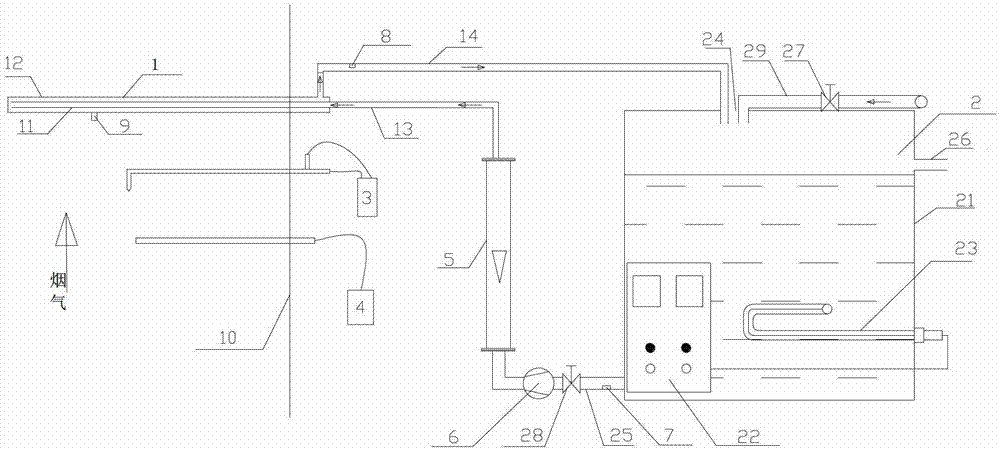

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

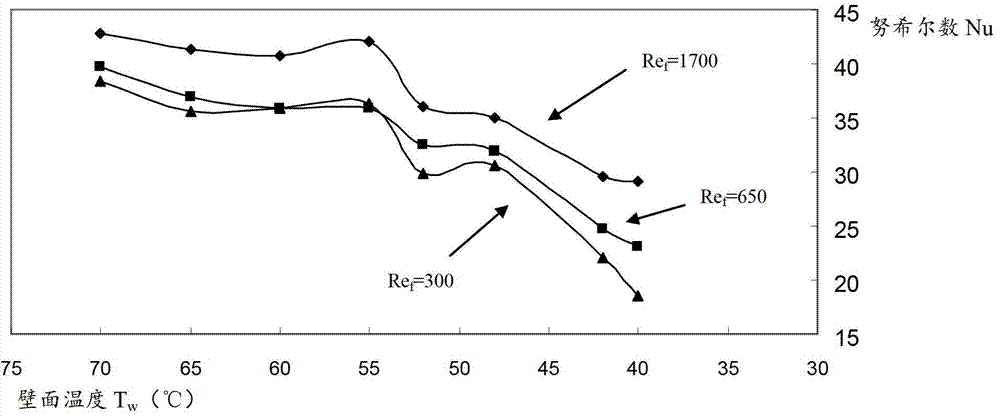

[0026] The present invention mainly utilizes the feature that the heat transfer coefficient of the heat exchanger will change significantly when a wet ash layer appears on the surface of the heat exchanger, and determines the sudden change in the heat transfer performance of the heat exchanger by observing the change of the heat transfer coefficient of the heat exchanger Critical temperature (engineering acid dew point), so as to guide the actual engineering design and avoid the heat exchanger working in the state of low heat transfer coefficient.

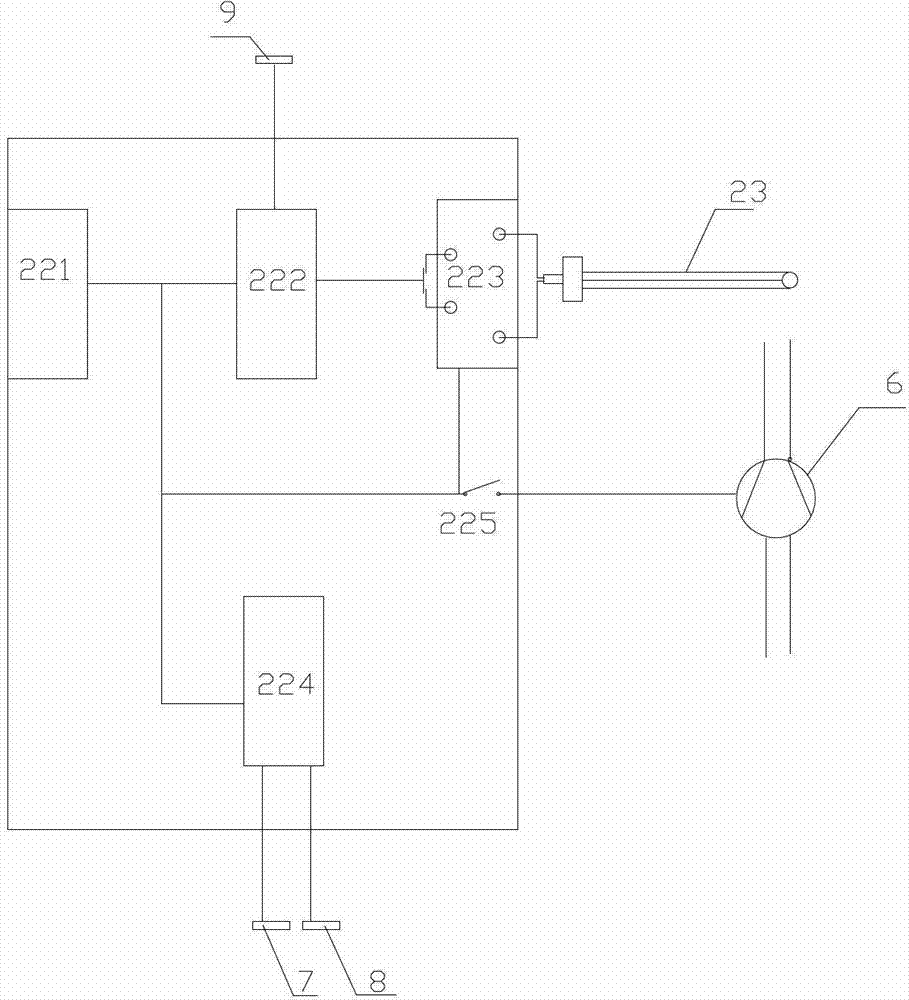

[0027] In the embodiment, the temperature control water tank is used to control the temperature of the cooling water in the water tank according to the measured value of the heat exchanger wall temperature, so as to achieve the effect of stabilizing the heat exchanger wall temperature, so as to set the heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com