Double-side scrubbing equipment between wafer production processes

A production process and wafer technology, applied in the field of double-sided scrubbing equipment, can solve the problems of low automation rate and production capacity, serious secondary pollution of wafers, and failure to achieve cleanliness, etc., to achieve good scrubbing effect and automation High, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the content of the present invention easier to understand clearly, the present invention will be described in further detail below according to specific embodiments in conjunction with the accompanying drawings,

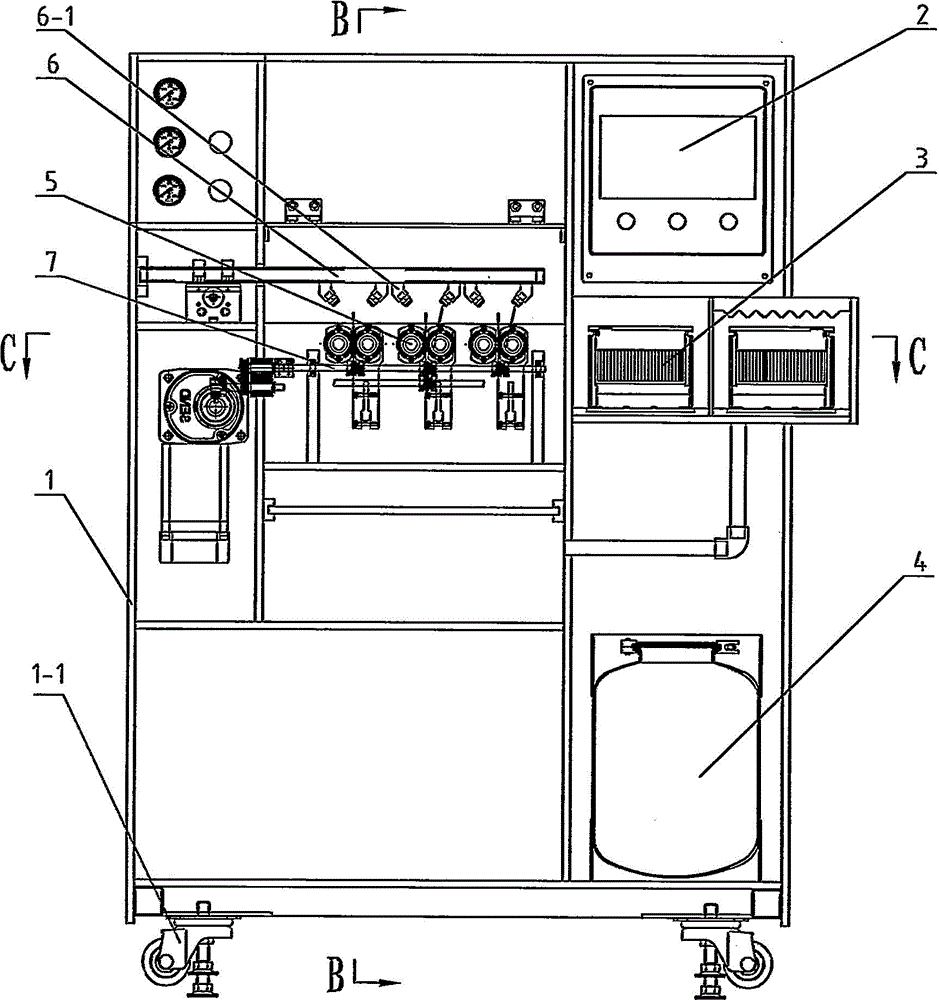

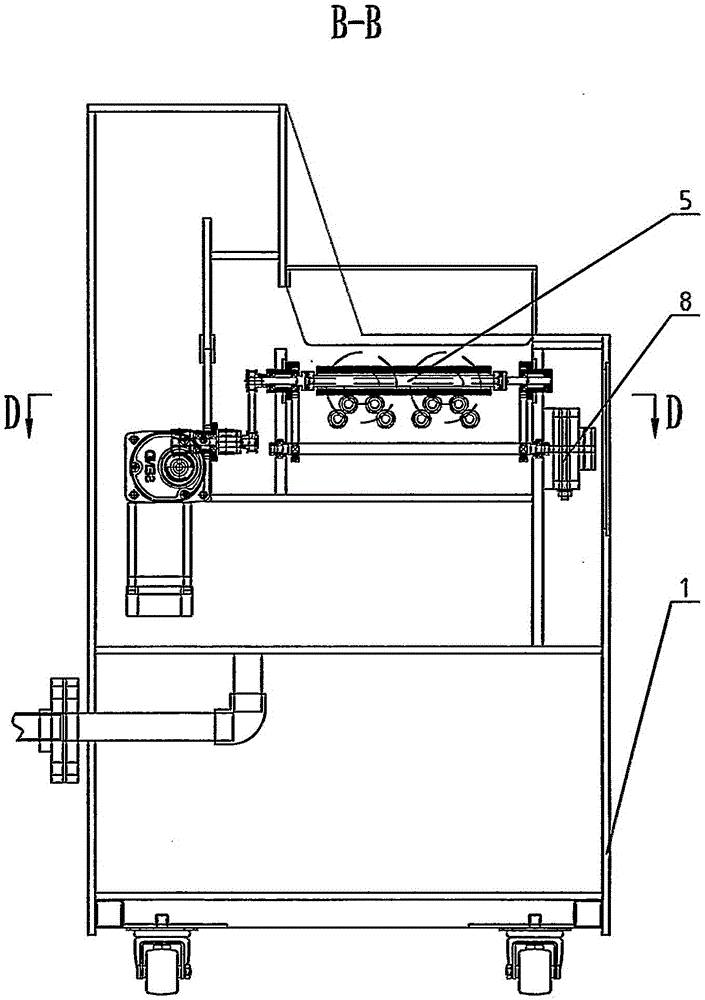

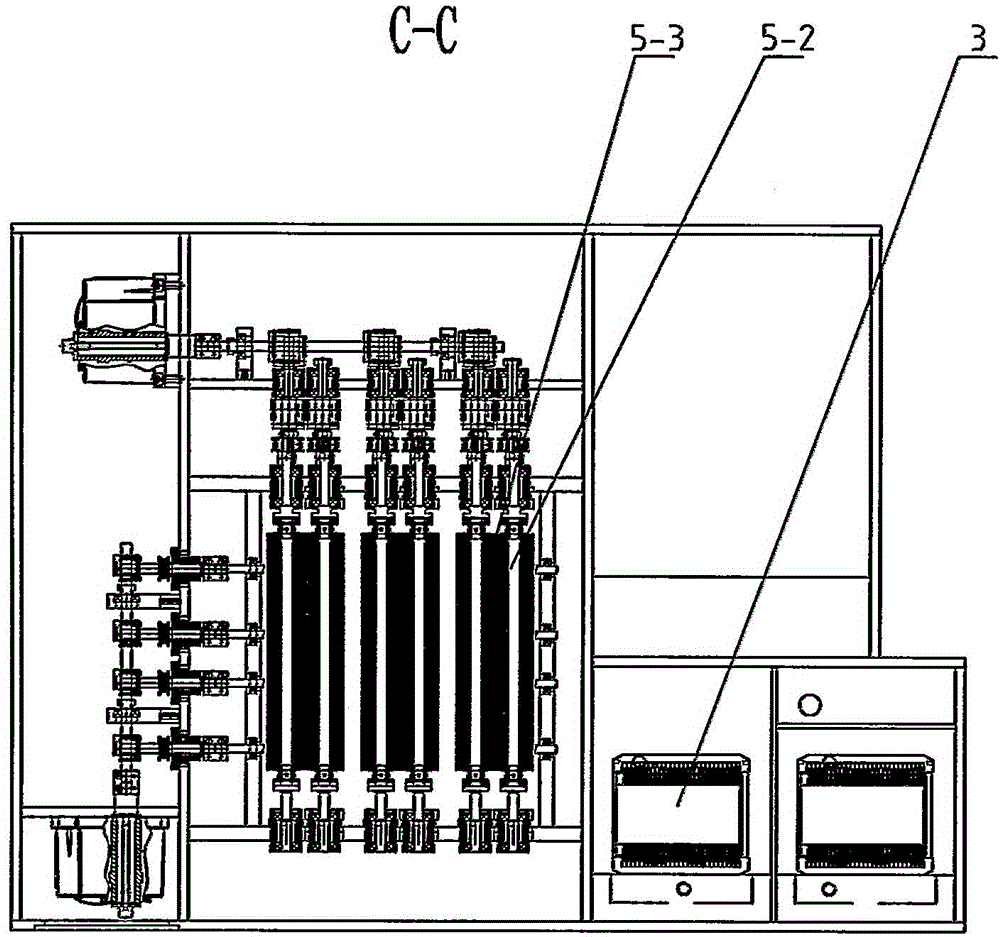

[0025] Such as Figure 1~13 As shown, a double-sided brushing equipment between wafer production processes, it includes a frame 1, a control system 2, a wafer storage device 3 and an active agent supply device 4; it also includes a double-sided brushing device 5, double-sided The scrubbing device 5 comprises a scrubbing support 5-1, a scrubbing mechanism and a first driving mechanism, the scrubbing bracket 5-1 is installed on the frame 1, and the scrubbing mechanism has many pairs of synchronously rotating scrubbing shaft assemblies 5-2 and is respectively sleeved on The brushes 5-3 on the corresponding brush shaft assembly 5-2, and the adjacent hair brushes 5-3 are located on both sides of the wafer to be cleaned, and the brush shaft assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com