Universal joint window cleaner

A technology of a window cleaner and a universal joint, applied in the field of cleaning supplies, can solve problems such as the inability to perform window cleaning work well, the inability to adjust the distance between the two magnets, and the inability to achieve the original intention of the design, so as to achieve better cleaning effects and improve User experience, labor-saving effect of magnetic adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

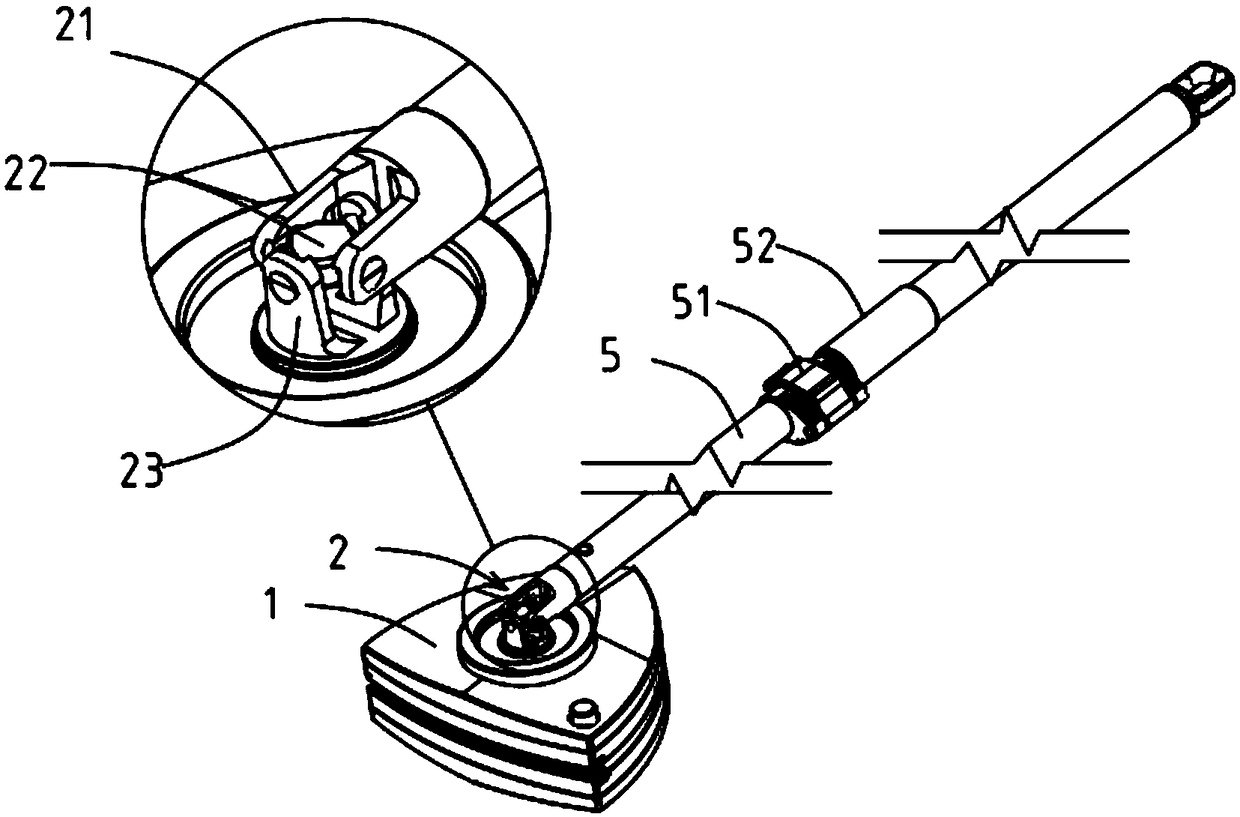

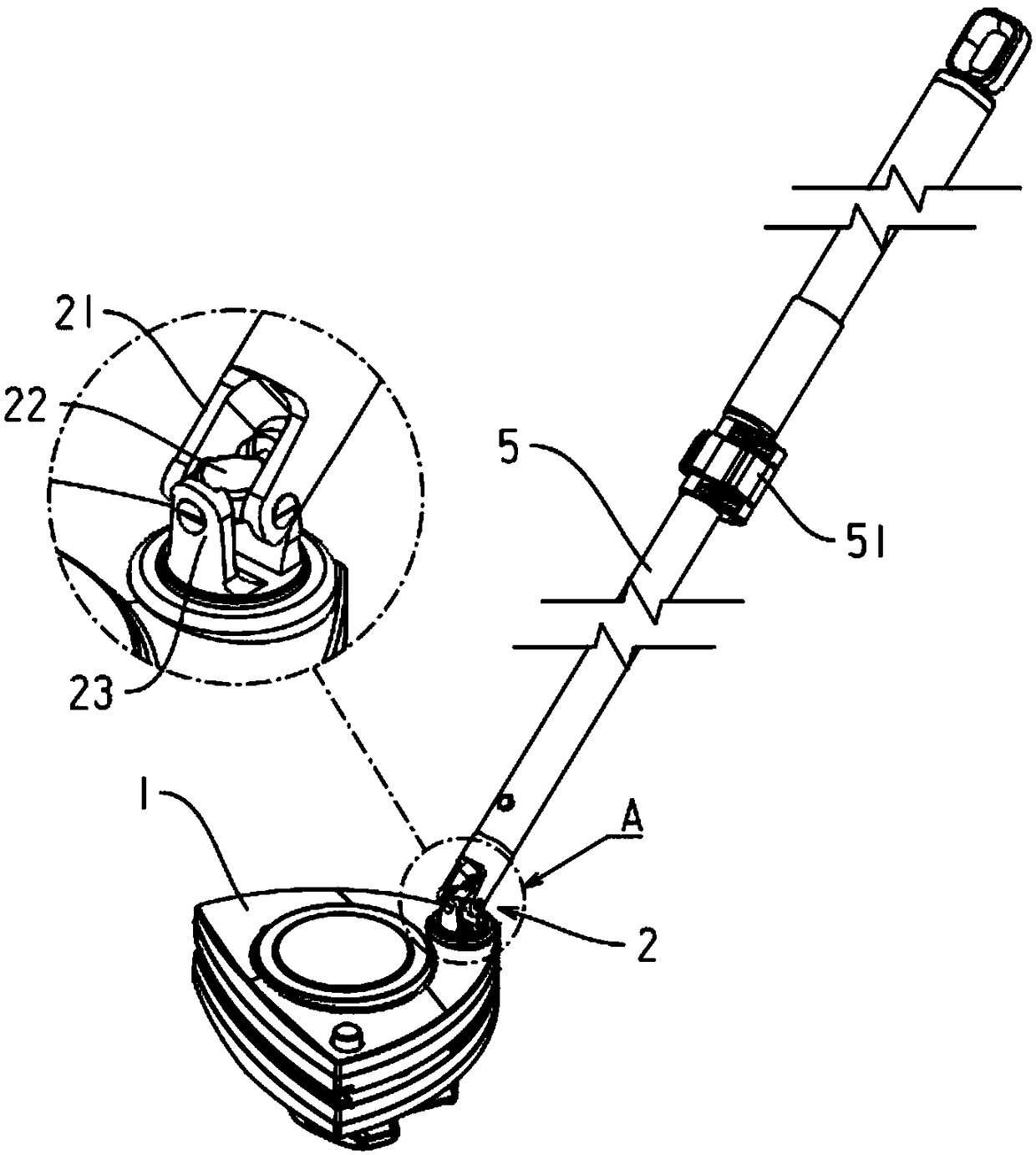

[0053] Embodiment 1: a kind of universal joint type window cleaner, as Figure 1.1 to Figure 2.1 as well as Figure 3 to Figure 9 As shown, it includes a wiper body 1 and a universal joint 2 that is movably connected to the wiper body, as Figure 1.1 and 2.1 As shown, the universal joint includes a first universal joint fork 21, a cross shaft 22 and a second universal joint fork 23, and the four ends of the cross shaft are four ends 221, as Figure 2.1 As shown, two of the opposite ends are rotatably connected with the first universal joint yoke, and the other two opposite ends are rotatably connected with the second universal joint yoke, while the second The universal joint fork is rotatably connected with the wiper body, and the wiper body can rotate in any direction through the universal joint.

[0054] The first universal joint yoke is one of the following two structures:

[0055] The first type is that the end of the first universal joint yoke away from the cross shaft...

Embodiment 2

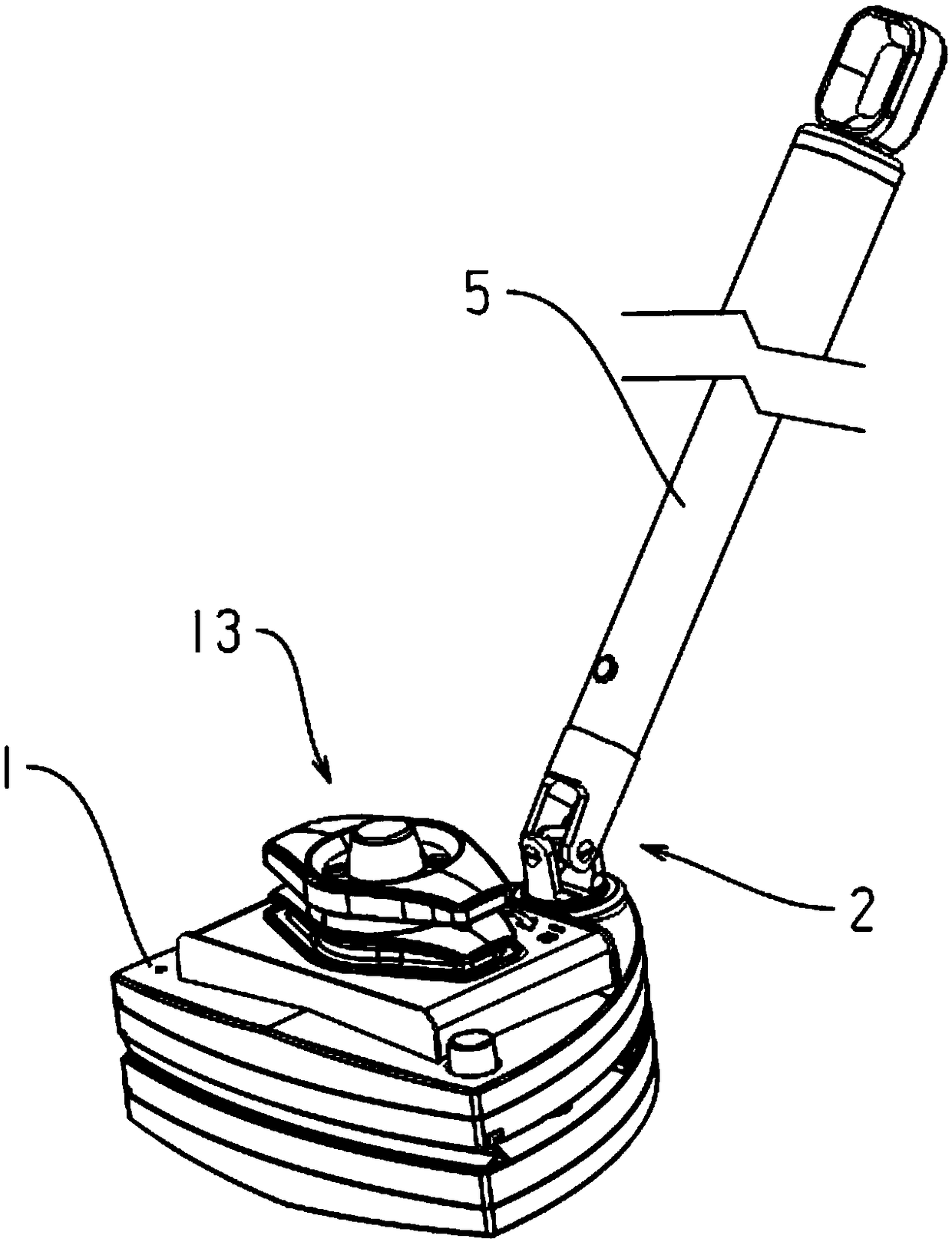

[0084] Embodiment 2: a kind of universal joint type window cleaner, as Figure 10As shown, the structure is the same as that of Embodiment 1, except that the magnetic adjustment mechanism includes a magnetic assembly 131, a screw 132, and a magnetic adjustment knob 133 that drives the magnetic assembly away from or close to the second wiper. One end of the screw is connected with the magnetic adjustment knob, and the other end of the screw passes through the screw hole 116 of the first wiper and is connected with the magnetic assembly;

[0085] The surface of the first wiper in contact with the glass is provided with an inwardly recessed groove 113, the thickness of the magnetic component is smaller than the depth of the groove, and the magnetic component is located in the groove and exposed to the first Wipe the surface of the contact body with the glass, and rotate the magnetic adjustment knob to drive the screw up and down so as to push the magnetic assembly away from or cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com