A micromechanical gyroscope with dual sensitive modes

A micro-machined gyroscope, sensitive modal technology, applied in the direction of the gyro effect for speed measurement, gyroscope/steering sensing equipment, measurement devices, etc., can solve the problem of low gain of the gyro system, affecting the sensitivity or resolution of the micro-machine gyroscope, and many restrictions. Degree of freedom micromachined gyroscope application field and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

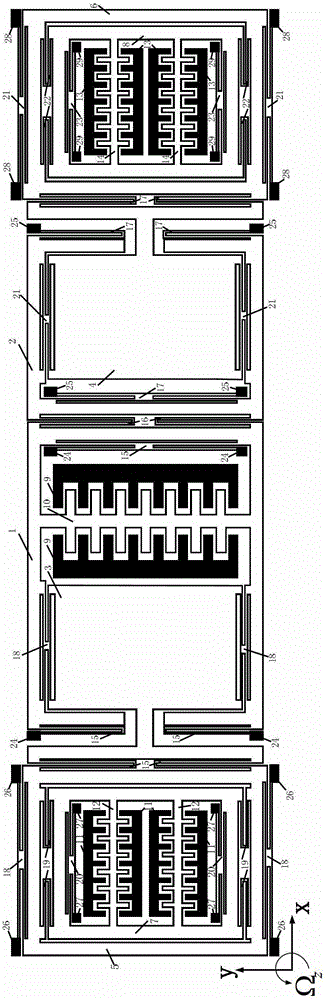

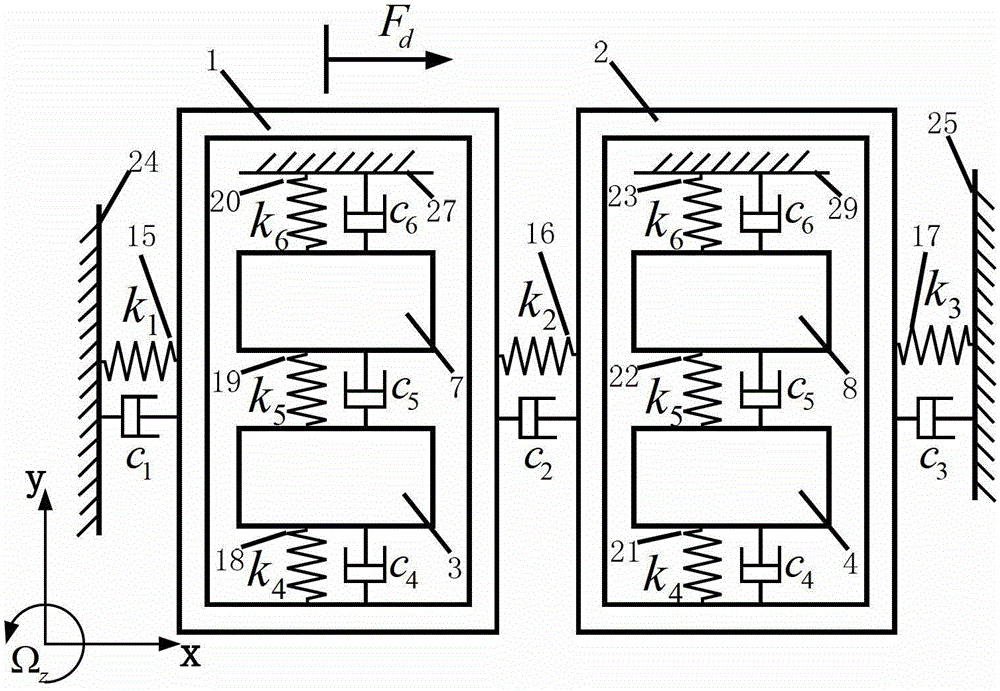

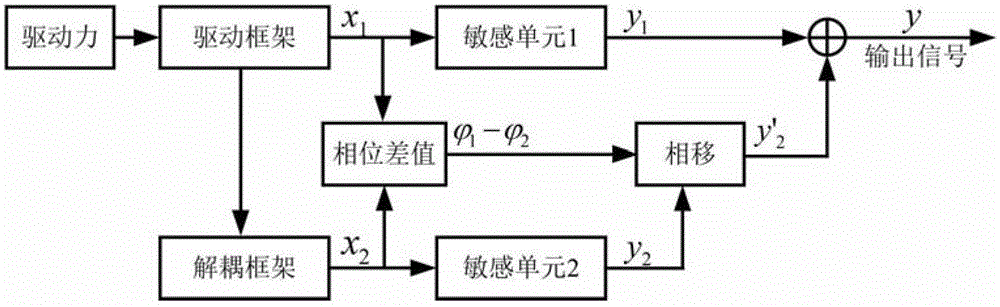

[0021] combine figure 1 The structure of the present invention mainly includes a drive frame 1, a decoupling frame 2, a static drive comb 9 and a dynamic drive comb 10, a first detection mass 3 and a second detection mass 4, a first detection frame 5 and a second detection mass. The frame 6 , the first sensitive mass 7 and the second sensitive mass 8 , the first static sensitive comb 11 and the first dynamic sensitive comb 12 , the second static sensitive comb 13 and the second dynamic sensitive comb 14 . The driving unit consisting of the static driving comb 9 and the dynamic driving comb 10 is arranged on the driving frame 1, the driving frame 1 is connected with the anchor point one 24 through the spring beam one 15, and the driving frame 1 and the decoupling frame 2 are connected through the spring beam two 16 is connected, and the decoupling frame 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com