Granular body configuration method and device

A configuration method and a technology of configuration devices, which are applied to lamination devices, chemical instruments and methods, turning equipment, etc., and can solve problems such as poor sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Hereinafter, Embodiment 1 of the present invention will be described with reference to the drawings.

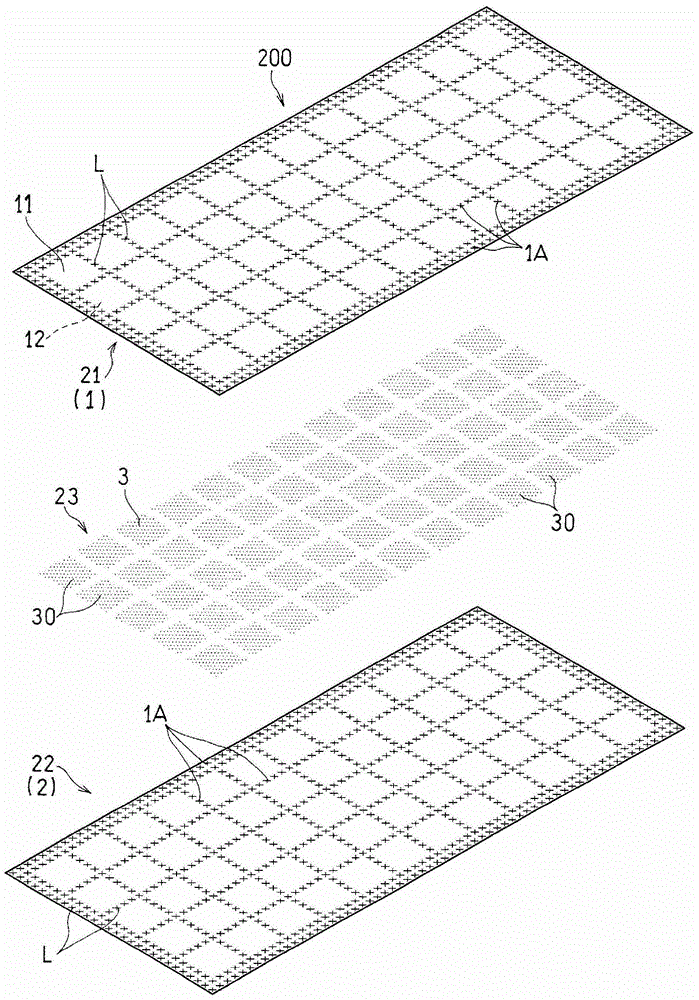

[0045] Figure 1 to Figure 7 Example 1 is shown.

[0046] Wearing item 1:

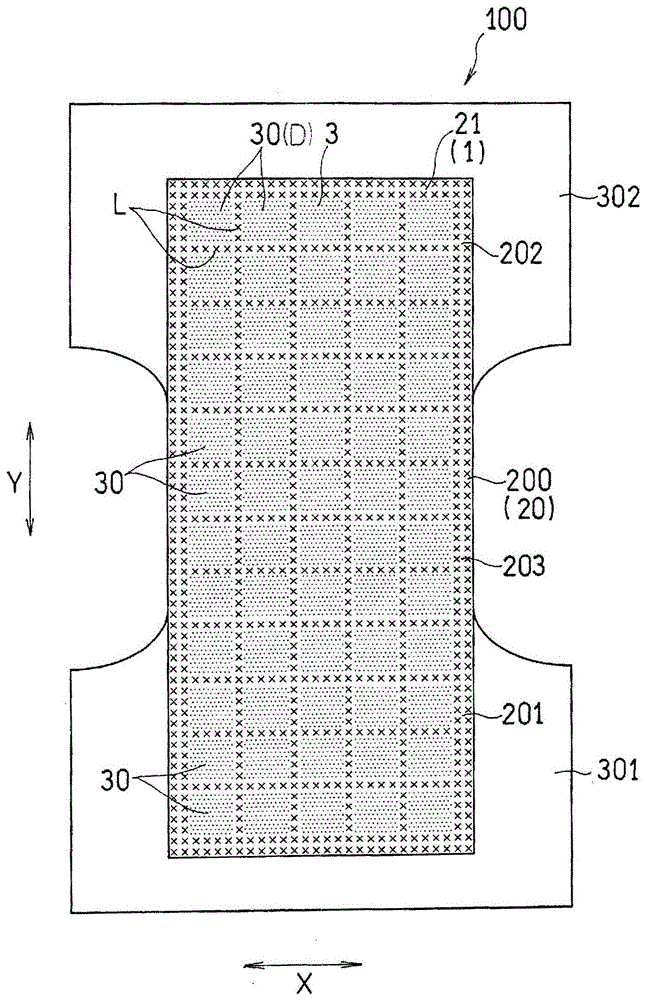

[0047] Such as figure 1 As shown, the wearing article 100 of this embodiment includes an absorbent body (diaper body) 200 , a front waist portion 301 , and a rear waist portion 302 . The absorbent main body 200 has a front part 201 covering the wearer's front waist, a back part 202 covering the wearer's back waist, and a crotch part 203 covering the crotch between the front part 201 and the back part 202 .

[0048] The crotch portion 203 is connected with the front portion 201 and the rear portion 202 and extends along the longitudinal direction Y perpendicular to the waistline direction X. The front waist portion 301 and the rear waist portion 302 may be joined together at the time of wearing, or may be joined in advance before wearing.

[0049] Three-dimensional gathers (not shown) may b...

Embodiment 2

[0102] Figure 8 ~ Figure 10 Example 2 is shown.

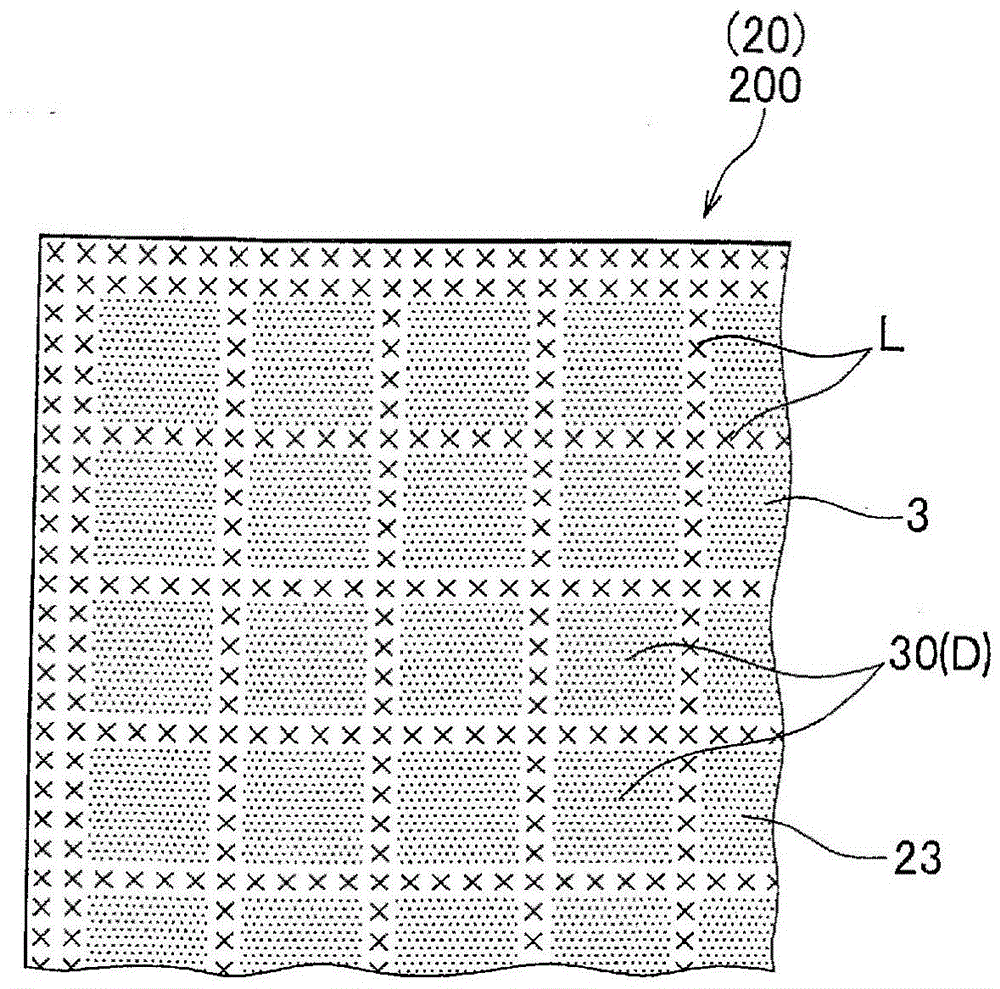

[0103] As shown in the above-mentioned figures, in the present embodiment, no ejection holes are provided in the non-suction region 4A. In the case of this example, also with the Figure 5 ~ Figure 7 Examples of similarly, such as Figure 8 ~ Figure 10 As shown, as the carrier fabric 1 proceeds to the downstream of the conveying route, the granular objects 3 in the non-suction region 1A of the carrier fabric 1 tend to gather in the suction region 1B.

[0104] In the second embodiment, the method of arranging the granular bodies 3 on the suction region 1B of the carrier fabric 1 is the same as that in the first embodiment, and thus its description is omitted. The situation of this embodiment 2 and Figure 5 Unlike Example 1, the effect of blowing off the granular bodies 3 by the blowing of the second air α2 from the spray hole 42 cannot be obtained. Therefore, the reliability of removing the granular bodies 3 on the non-at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com