Injection mold for beach shoes and method for injecting soles of beach shoes using the injection mold for beach shoes

An injection mold and beach technology, which is applied in the field of beach shoe injection molds, can solve the problems of polyurethane leakage, the insole edge arcs are not tightly fitted, and the molds are not easy to fit, so as to reduce the phenomenon of material leakage and reduce material leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

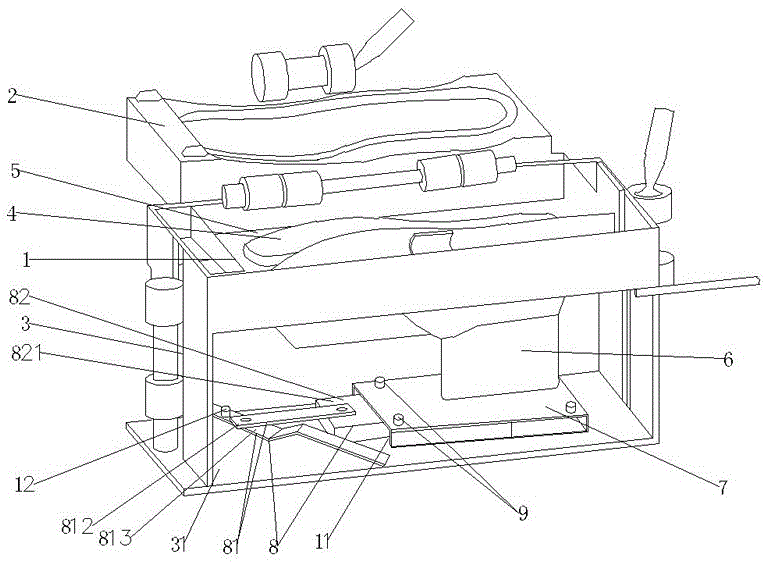

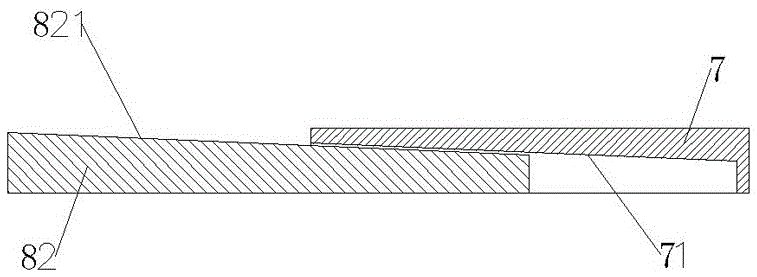

[0011] Such as figure 1 As shown, the beach shoes injection mold provided by the present invention includes a last mold, a clamp mold 1, a bottom mold 2 and a mold frame 3, and the shoe last 4 is surrounded by the clamp mold 1 and the bottom mold 2 to form an injection molding cavity. The mold 1 has a shoe last placement groove 5. When the mold is closed, the clamping mold 1 is turned over and closed relative to the bottom mold 2. The shoe last 4 is inserted into the shoe last placement groove 5. The injection mold is equipped with a shoe last fixing part 6. The shoe last 4 is fixed on the shoe last fixing part 6, and the shoe last fixing part 6 can move up and down relative to the mold frame 3, and the injection mold is equipped with a jack that can push the shoe last fixing part 6 toward the injection molding cavity. device. In this embodiment, the mold frame 3 is provided with a jacking device corresponding to the shoe last fixture 6, and the jacking device includes a jack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com