Automatic punching jig for injection-molded part

A technology for automatic punching and injection molding, which is applied in metal processing and other directions, and can solve problems such as time occupation, inaccurate product size and shape, and reduced production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

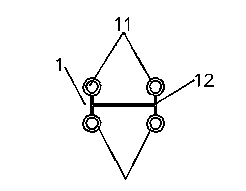

[0036] see Figure 1-Figure 4 , as shown in the legend therein, is an automatic punching fixture for injection molded parts, which is used for punching injection molded parts 1 to form four injection molded products 11 and one injection molded waste 12 .

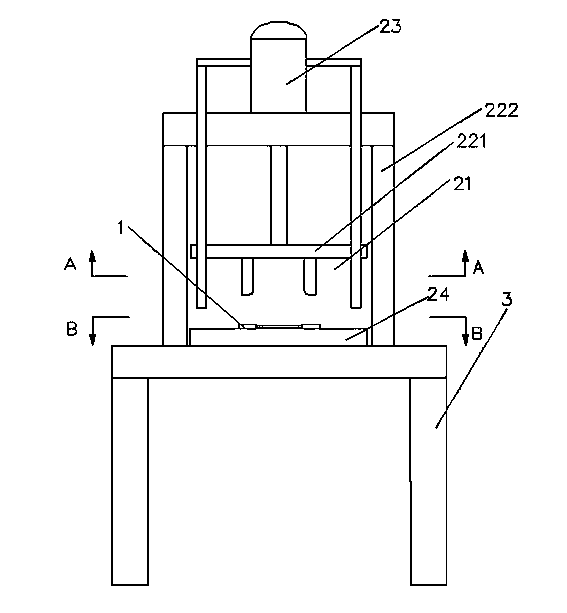

[0037] The above-mentioned automatic punching fixture includes a punching mechanism, a control device (not shown in the figure) for controlling the above-mentioned punching mechanism, and a frame 3 for carrying the above-mentioned punching mechanism and the control device. The mechanism includes a cutter assembly, a punching plate assembly, a punching plate feed cylinder 23 and a support table 24:

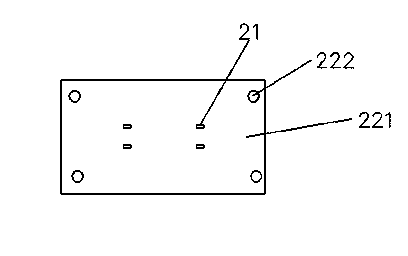

[0038] The cutter assembly includes four punching cutters 21 for punching the injection molded part 1;

[0039] The above punching plate assembly includes a punching plate 221 for fixedly installing the above four punching tools 21 and four punching guide rods 222 for guiding and connecting the punching plates 221;

[0040] The...

Embodiment 2

[0049] see Figure 5 and Figure 6 , as shown in the legend therein, the rest are the same as the embodiment 1, the difference is that the above-mentioned punching mechanism also includes a pressing plate 41 for pressing or releasing the injection molded part 1 and a pressing plate for guiding connection The binder guide hole 42 of 41, the binder guide hole 42 is arranged on the binder plate 41; the punching guide rod 222 is slidably connected in the binder guide hole 42 and is limited to the outlet of the binder guide hole 42; the binder plate 41 There are four hollow parts 411 that allow the punching tool 21 to pass through.

[0050] The following describes the process of using the automatic punching fixture for injection molded parts in this embodiment to punch injection molded parts to form injection products and injection molding waste, including the following steps:

[0051] The first step is to place the injection molded part 1 on the support table 24, and make the in...

Embodiment 3

[0057] see Figure 7 , as shown in the legend therein, the rest are the same as the embodiment 2, the difference is that there is also a press for elastically supporting the punching plate 221 and the pressing plate 41 between the punching plate 221 and the pressing plate 41. The material spring 43 and the pressing material spring 43 are sheathed on the punching guide rod 222 .

[0058] In this embodiment, a pressing spring is added, which can make the relative movement between the punching plate and the pressing plate more moderate, and can realize the reset of the position of the pressing plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com