Warp yarn force application method and warp yarn tension adjustment device of warp yarn tension adjustment device of cord fabric weaving device

A tension adjustment and cord fabric technology, used in textiles and papermaking, textiles, looms, etc., can solve the problems of time-consuming and laborious, and immediately stop again, and achieve the effect of preventing warp tension from vibrating and preventing false detection of warp breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

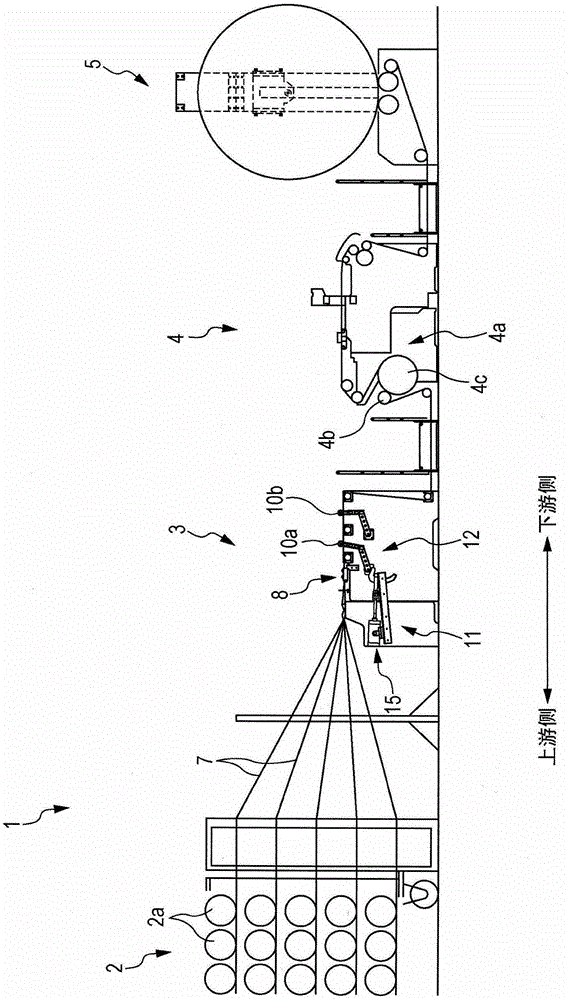

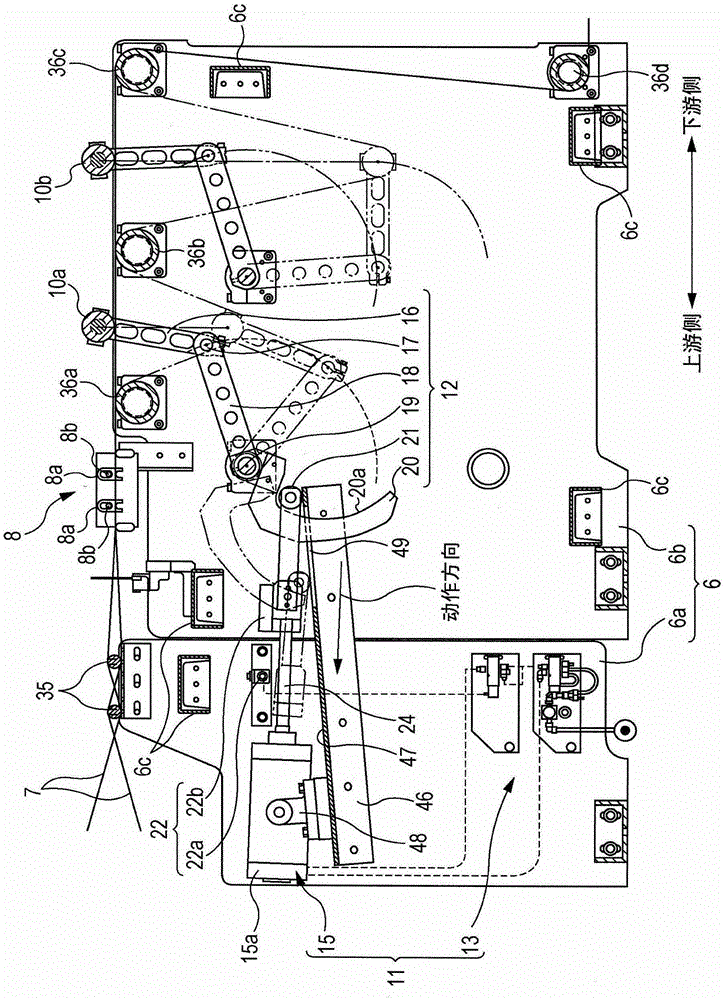

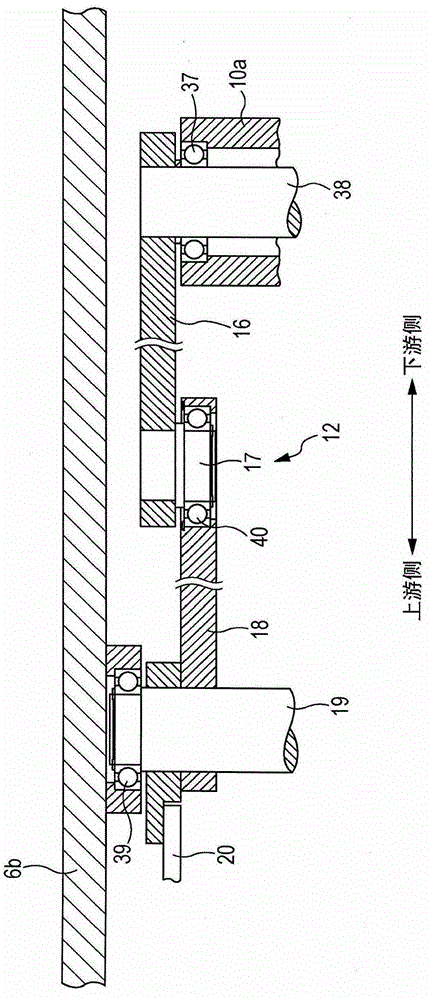

[0062] Below, based on Figure 1-Figure 7 An embodiment of the present invention will be described.

[0063] figure 1 An example of the cord weaving apparatus 1 to which the warp urging method and apparatus thereof according to the present invention are shown is shown. figure 1 The main structure of the shown cord fabric weaving device 1 includes: a warp creel device 2, a warp tension adjustment device 3, a loom 4, and a class-based winding device 5, the warp creel device 2 supplies warp yarns 7, and the warp yarns The tension adjusting device 3 adjusts the tension of the warp yarn 7, the loom 4 performs weaving, and the class-based winding device 5 winds the woven cord fabric.

[0064] The creel device 2 is provided with a plurality of columns not shown in multiple rows and rows, and a plurality of bobbins 2a are neatly attached to these columns. Warp yarns 7 are simultaneously drawn out from a plurality of bobbins 2 a on the creel device 2 and guided to the loom 4 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com