Separator welding device and separator welding method

一种分离片、熔接的技术,应用在层压装置、化学仪器和方法、连接等方向,能够解决周期变长等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

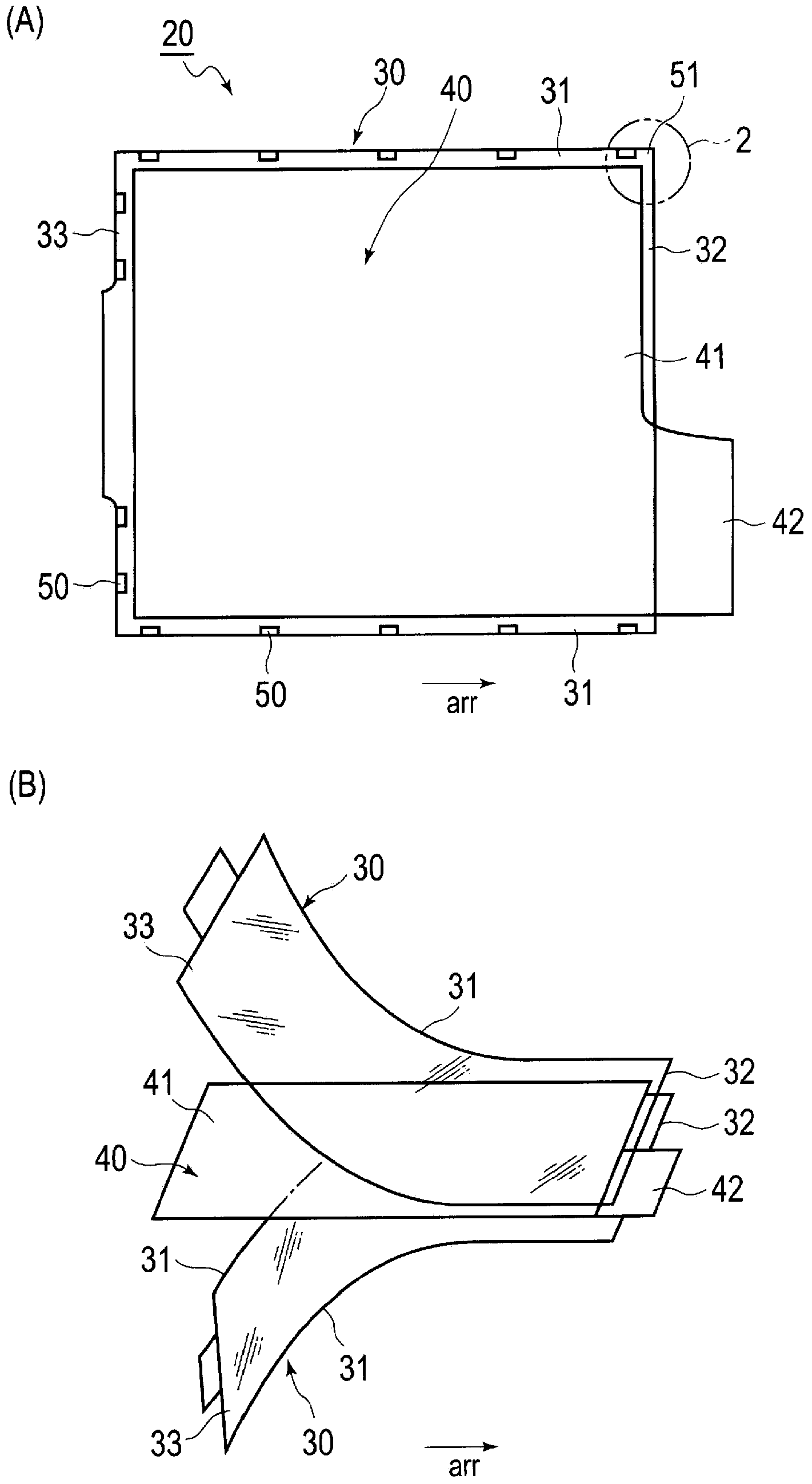

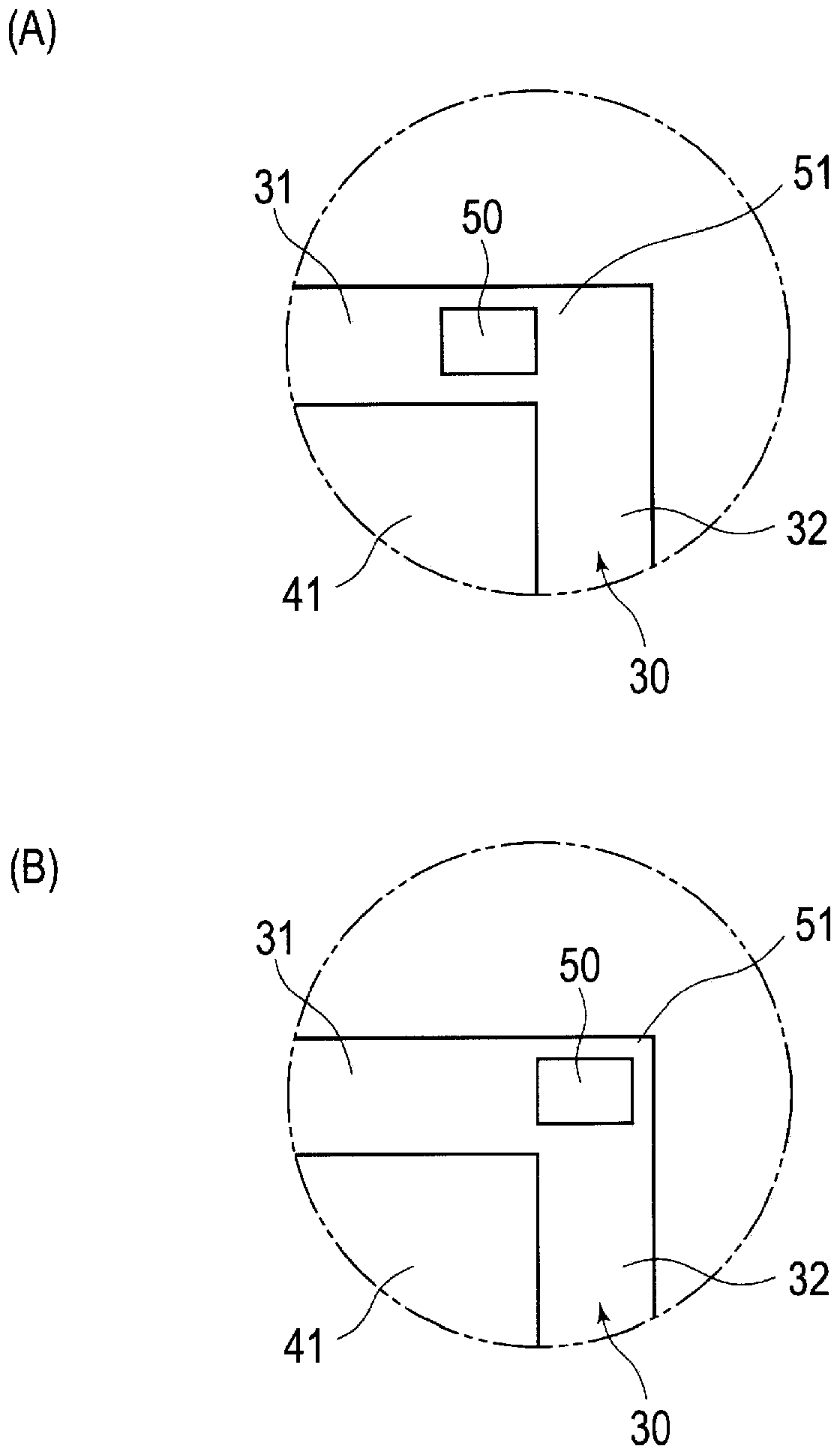

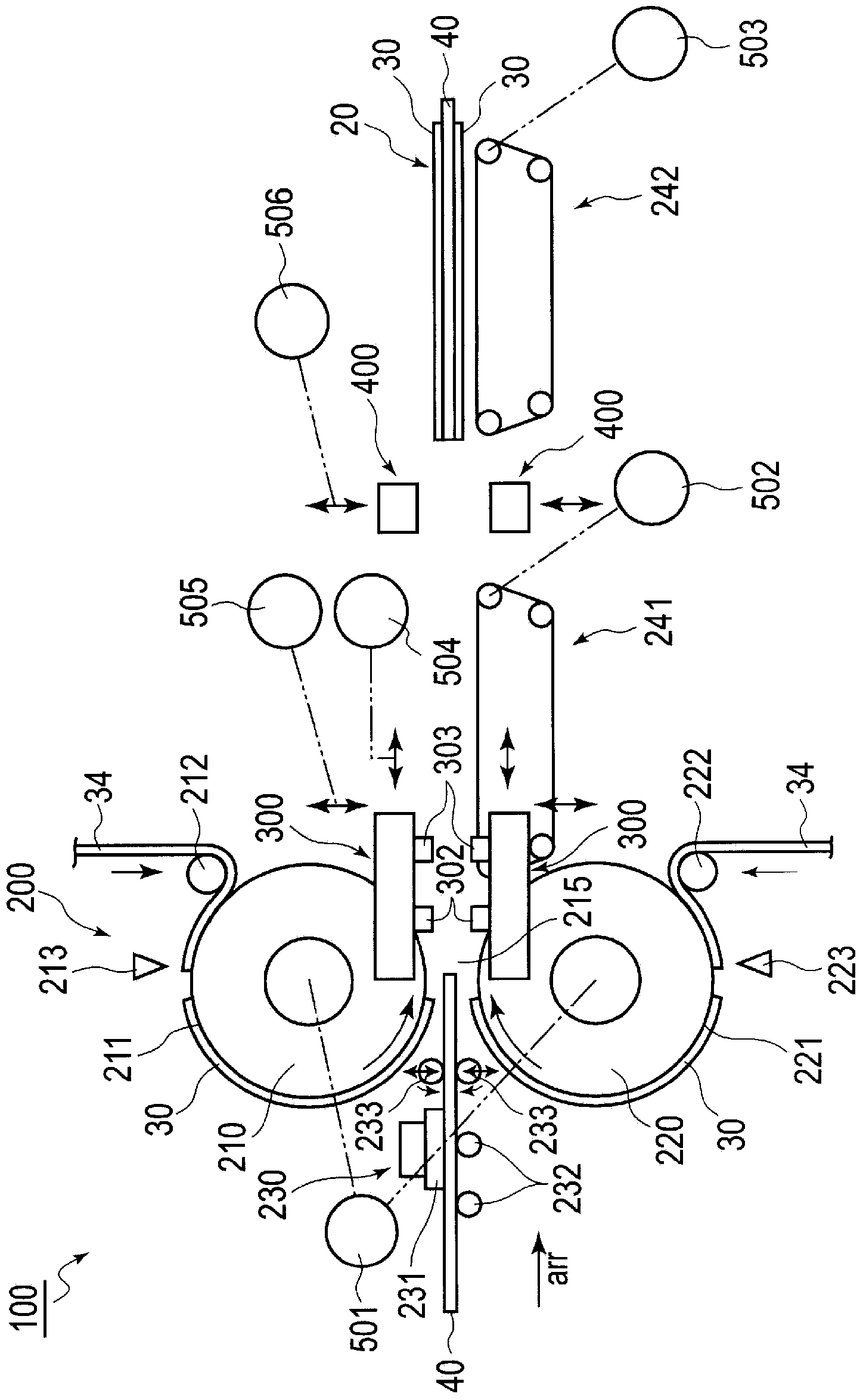

[0022] Embodiments of the present invention will be described below with reference to the attached drawings. In addition, in description of drawings, the same code|symbol is attached|subjected to the same element, and repeated description is abbreviate|omitted. The dimensional ratios of the drawings are exaggerated for convenience of description and are different from actual ratios.

[0023] in addition, figure 1 of (A), figure 1 (B) and image 3 The indicated arrow arr indicates the transport direction in which the electrode 40 and the pair of separators 30 are transported when the bagged electrode 20 is manufactured. exist figure 1 of (A), figure 1 (B) and image 3 In the figure, the right side in the figure is the downstream side of the conveying direction, which is called "front" in each member, and the left side in the figure is the upstream side in the conveying direction, called "rear" in each member. In addition, the edges of the separator in the direction inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com