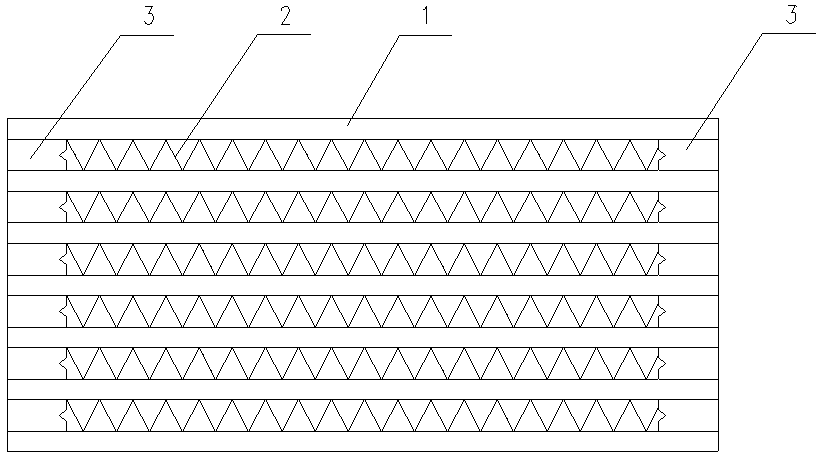

Core of plate-fin heat exchanger

A technology of plate-fin heat exchangers and cores, which is applied in the direction of heat exchangers, indirect heat exchangers, heat exchange equipment, etc. The problems such as large vibration amplitude of the body can be solved, and the effect of improving mechanical strength, reducing vibration amplitude and increasing welding distance can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

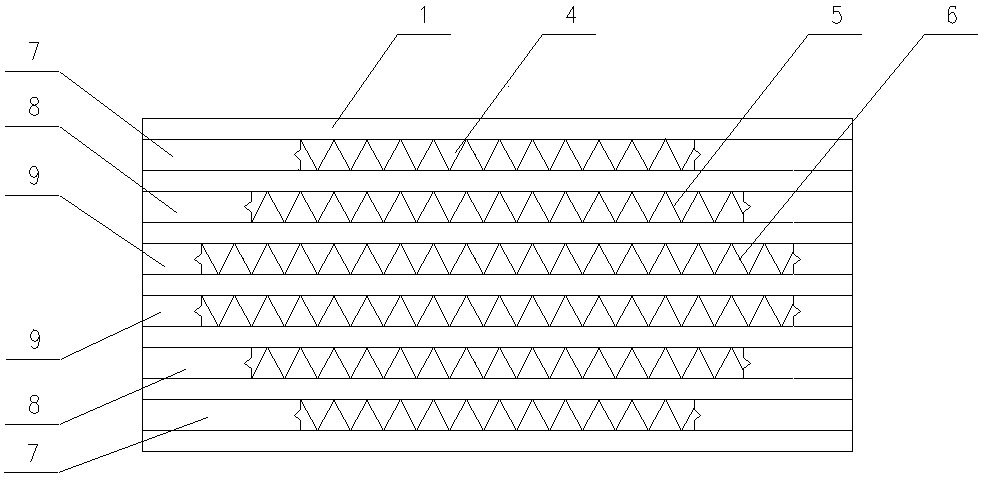

[0010] See figure 2 , the core body of the plate-fin heat exchanger, which includes several cooling tubes 1 and outer fins, the cooling tubes 1 are arranged at intervals, the outer fins are installed between adjacent cooling tubes, and are located in the gap between adjacent cooling tubes Seals are installed at both ends, and the seals are welded and connected to the adjacent heat dissipation pipes. The seals 7, 8, and 9 at the four corners of the core are arranged in a trapezoidal shape, and the length of the seal 7 located outside the core is longer than that located inside the core. The lengths of 8 and 9; the lengths of the seals 7, 8 and 9 at the four corners of the core body are 20mm, 15mm and 10mm from outside to inside. In the figure, 4, 5 and 6 are outer fins with different lengths, wherein the length of the outer fin 6>the length of the outer fin 5>the length of the outer fin 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com