Anti-detachment chainwheel having forced recessed face at chain tooth root portion

A force concave, root technology, used in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of small number of teeth, chain falling off, detachment, etc., to improve the effect of easy detachment from the sprocket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

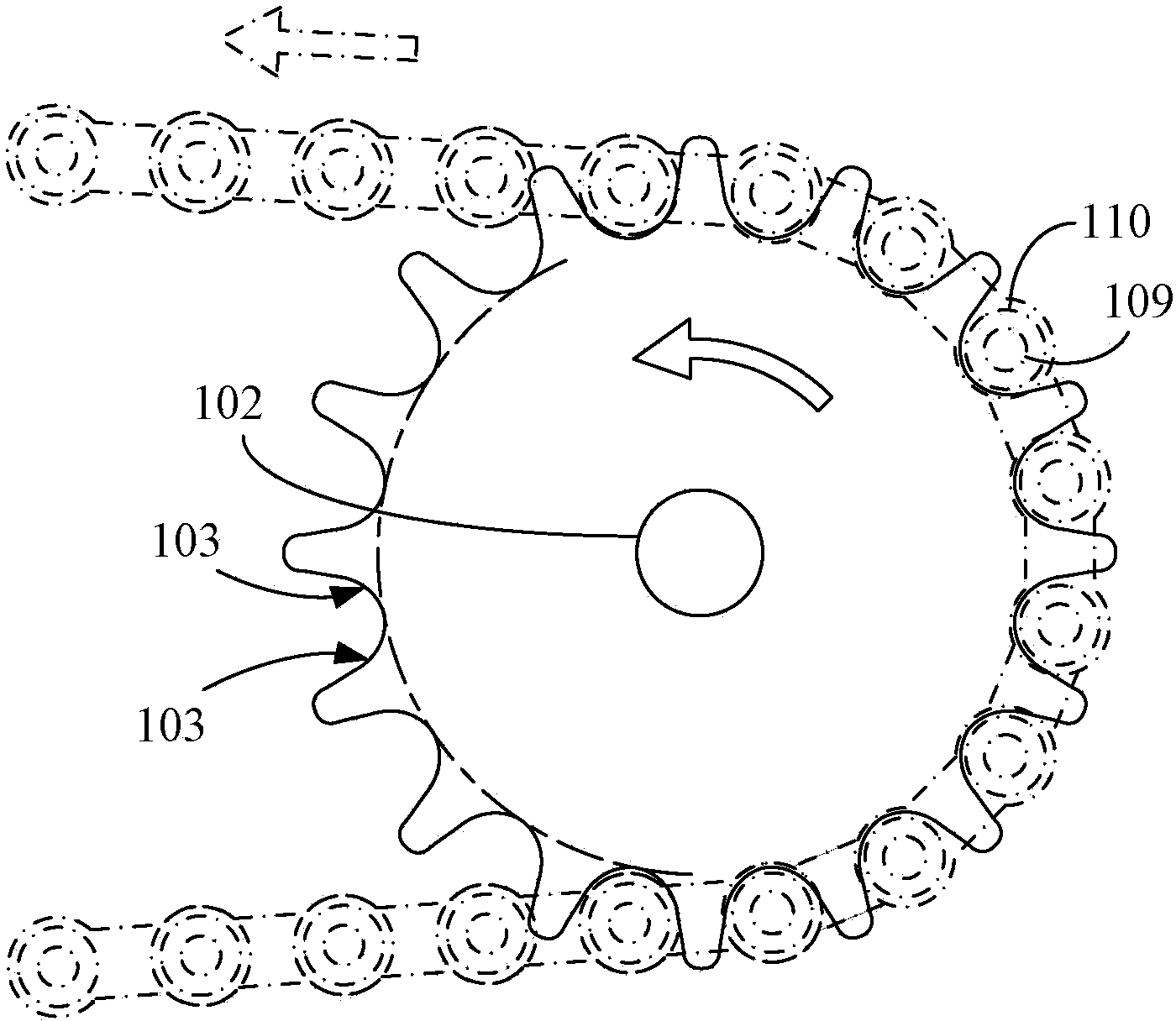

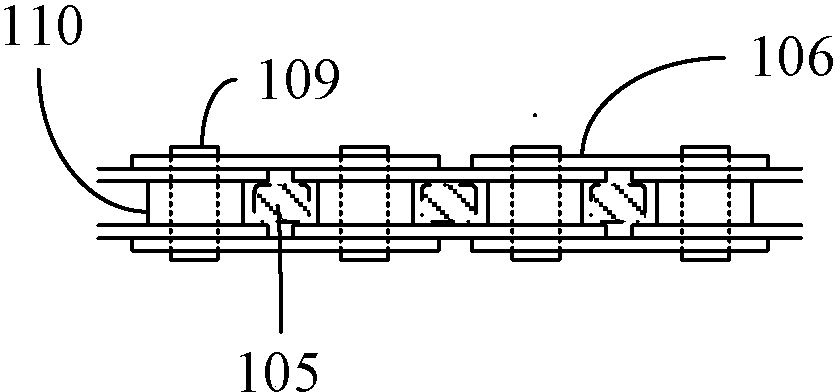

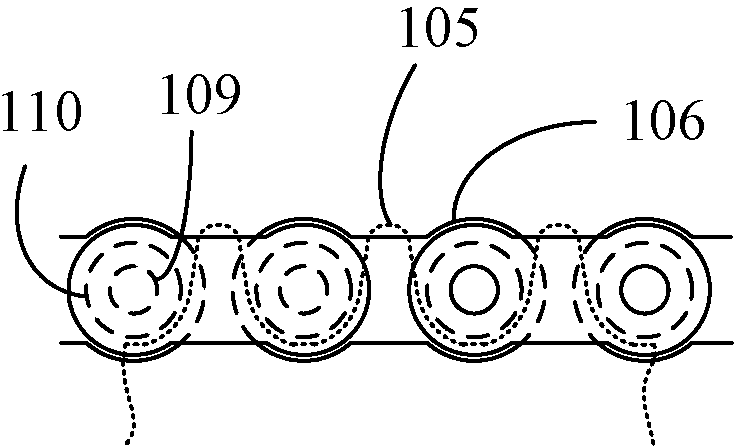

[0040] The present invention provides an anti-off sprocket with a stressed concave surface at the root of the sprocket surface. When the sprocket is driven by the chain, the chain roller 110 sleeved by the chain connecting pivot 109 can be pressed against the root of the sprocket surface. The stressed concave surface 104 further improves the shortcoming that the chain is easily detached from the sprocket. The root of the sprocket surface has an anti-off sprocket with a stressed concave surface, including the application structure of single-drive steering and double-drive steering.

[0041] Figure 4 Shown is a schematic diagram of the tooth shape structure of the single-drive stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com