Front drive reciprocating type stepless labor-saving bicycle

A reciprocating, bicycle technology, used in rider drive, vehicle components, vehicle gearboxes, etc., can solve problems such as road congestion and difficulty in long-distance riding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

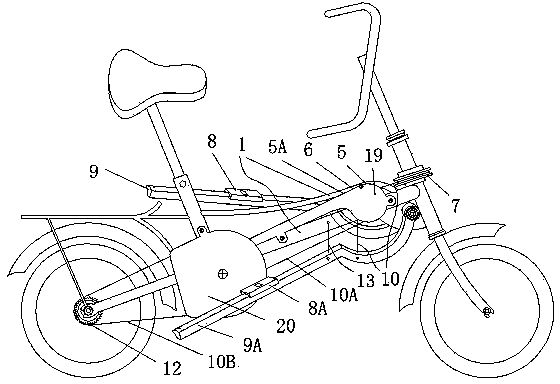

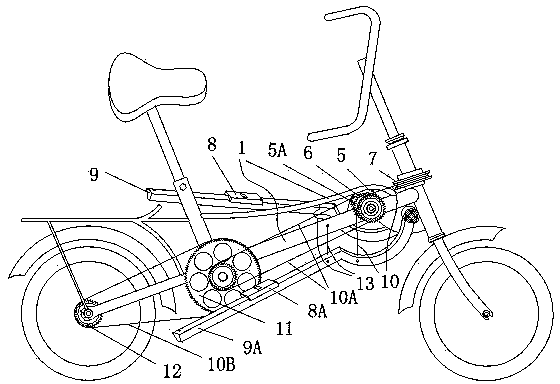

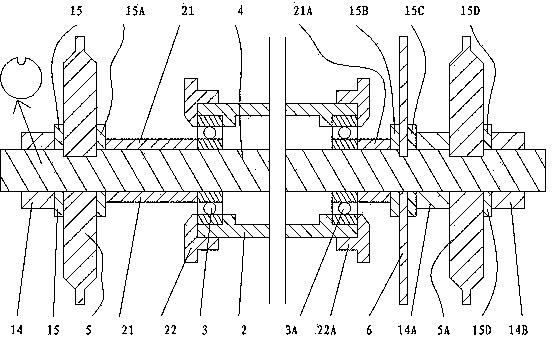

[0009] figure 1 Or 2, 3, and 4 show: the front-drive reciprocating stepless labor-saving bicycle includes the existing parts of the bicycle; a shaft sleeve (2) is welded at the rear part of the front end of the vehicle frame (1), and the warp shaft with the bearing (3, 3A) One end of the rod (4) is fixed with a flywheel (5), and the other end is fixed with a sprocket (6) and another flywheel (5A); the outer diameter of the front fork tube is sleeved with a bearing pulley (7); A shaft rod is fixed on the vehicle frame, and its two ends are connected with the left and right levers (9, 9A) of the pedals (8, 8A) through bearings; After the pulley (7) occludes the two flywheels (5, 5A), the two ends are connected to the rear of the front ends of the two levers (9, 9A); the right end of the central axis of the vehicle frame has a variable-diameter transmission wheel (11) with a pinion through a chain (10A) ) to connect the sprocket wheel (6), connect the rear ring flywheel (12) th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com