Fixture structure of inner plate of automobile left longitudinal beam

A technology for left longitudinal beams and automobiles, applied to measuring devices, instruments, and mechanical devices, etc., can solve the problems of complex detection process, low efficiency, and long cycle, and achieve the effects of high accuracy, high efficiency, and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

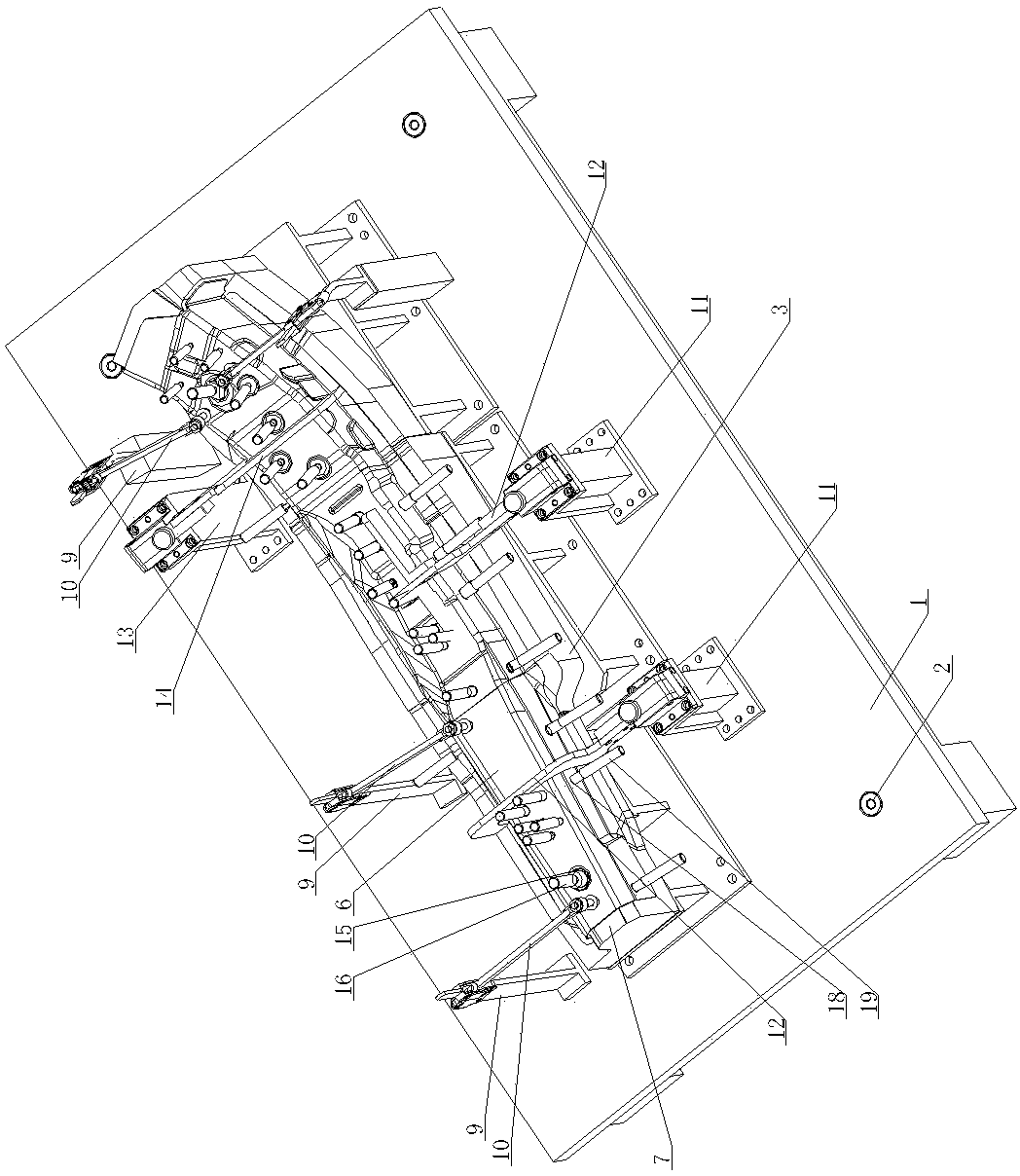

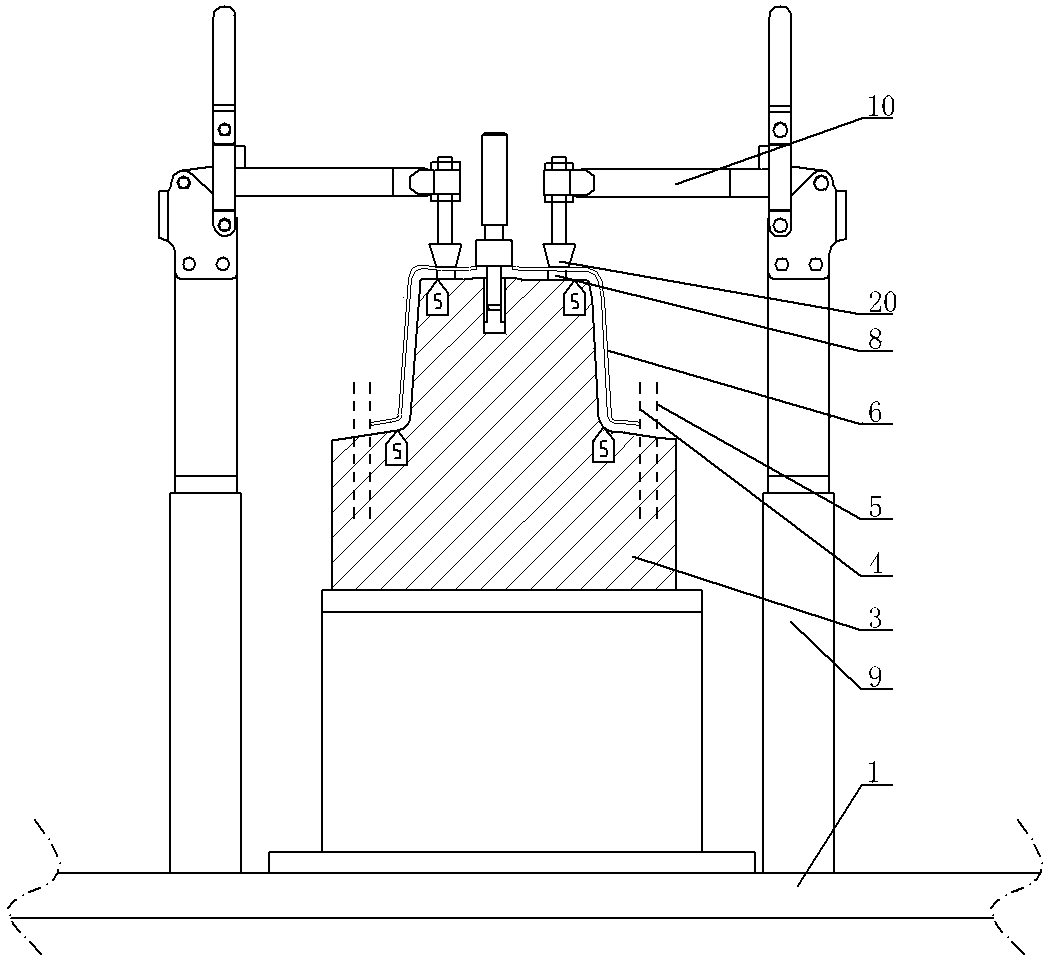

[0010] See Figure 1 to Figure 3 , which includes a base plate 1, three corner positions of the base plate 1 are respectively provided with reference sleeves 2, the upper end surface of the base plate 1 is provided with a simulation block 3, and the outer side of the simulation block 3 forms the inner contour structure of the left longitudinal beam inner plate 6, its bottom The 0 line and the 3mm line are drawn on the surface contour boundary respectively. The 0 line is the standard contour line 4, and the 3mm line is the error range line 5 which extends the standard contour line outward by 3mm. The front end of the simulation block 3 is protruding for the limit 7. The positions of the front, middle and rear ends of the outer side of the simulation block 3 are provided with upwardly convex positioning bumps 8, and the middle and rear positions of the inner side of the simulation block 3 are provided with upwardly convex positioning bumps 8. The inner surface of the plate 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com