A High Frequency Acoustic Focuser

A high-frequency sound wave and focuser technology, which is applied in the direction of sound-emitting devices, instruments, sensors, etc., can solve the problems of poor low-frequency effect and large angle, and achieve the effect of high work efficiency, output power and sound pressure level improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

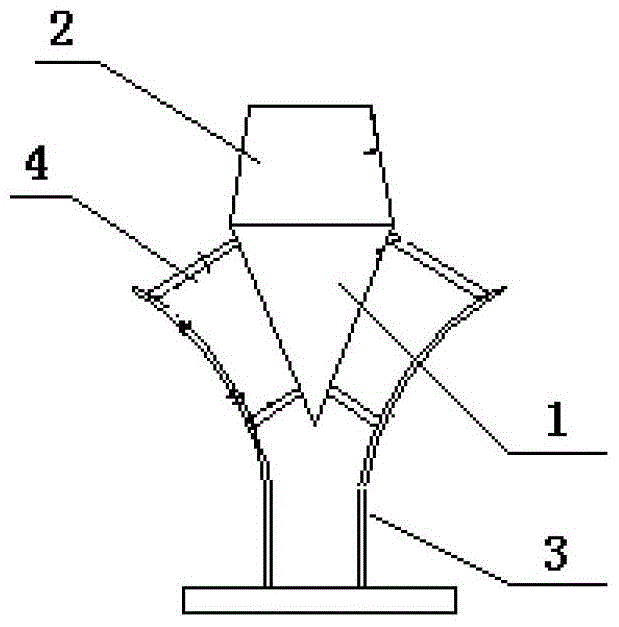

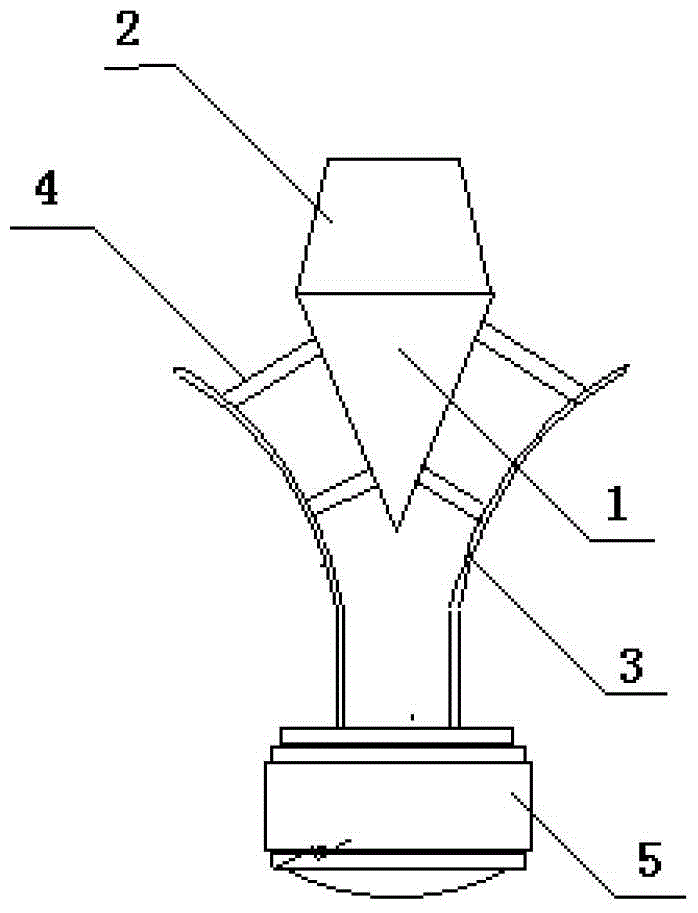

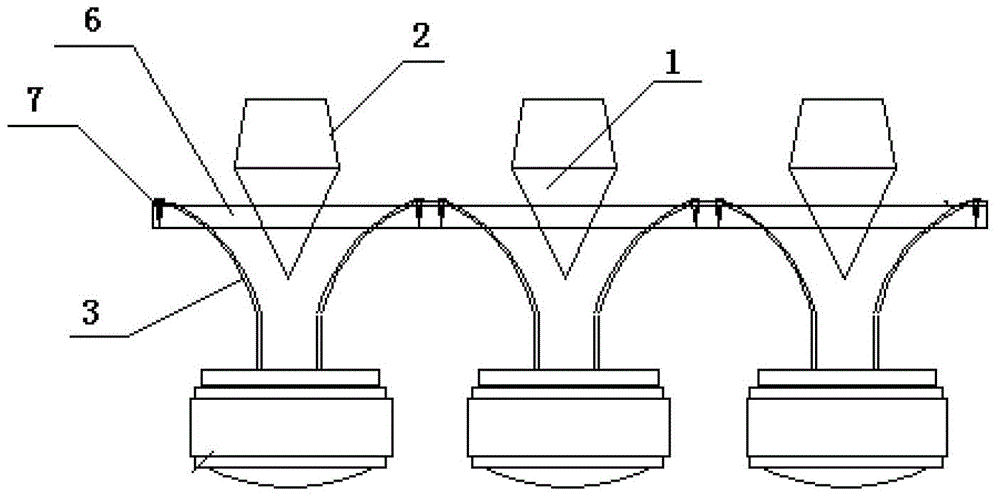

[0031] Such as figure 1 Shown, the high-frequency acoustic wave focuser that the present invention provides comprises a conical core 1, circular frustum 2 and tweeter horn 3; The bottom surface diameter of this conical core 1 is 99mm, and height is 91mm, and cone angle is 40 °, and its surface is Plane; the height of the round platform core 2 is 41mm, the diameter of the large end is 99mm, the diameter of the small end is 50mm, and the angle of the platform is 22°; the tweeter horn 3 is an arc horn with a length of 109.8mm and a wide mouth (diameter) It is 152.8mm, and its small mouth width (diameter) is 36mm; the big head end of the round platform core 2 is connected with the bottom surface of the conical core 1; the conical core 1 is set in the cavity of the tweeter horn 3, and is made of hard mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com