Device for finish machining of inner hole by means of steel ball

A steel ball and inner hole technology, applied in the field of inner hole processing devices, can solve problems such as limited efficiency, and achieve the effect of increasing production efficiency and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation plan

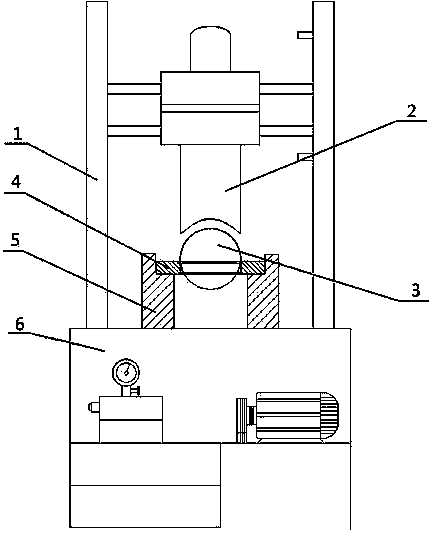

[0012] Such as figure 1 Shown, the present invention is a kind of device that utilizes steel ball to inner hole finish machining, and it comprises hydraulic machine 1, hydraulic head 2, fixture 5 and hydraulic table 6, and the middle position of described hydraulic machine 1 is equipped with hydraulic head 2; A fixture 5 is installed on the working surface of the hydraulic table 6, corresponding to the hydraulic head 2; the stamping end of the hydraulic head 2 is an inwardly concave arc, which matches the curvature of the surface of the steel ball 3; the fixture 5 is hollow and concave. The font is beneficial to the placement of the workpiece 4 and the extruding work of the steel ball 3.

[0013] The inside of the hydraulic table 6 is equipped with a hydraulic gauge and a motor, which are the power control of the hydraulic head 2 .

[0014] When working, put the workpiece 4 flat in the special fixture 5, then put the steel ball 3 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com