Hydraulic machine provided with device for inner hole finish machining through steel ball

A technology for finishing inner holes and hydraulic presses, applied in the field of hydraulic presses, can solve problems such as limited efficiency, and achieve the effect of increasing production efficiency and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation plan

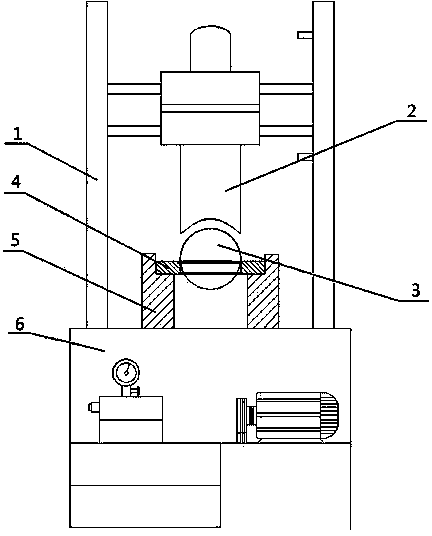

[0011] Such as figure 1 As shown, the present invention is a hydraulic press equipped with a device for finishing inner holes utilizing steel balls, which includes an inner hole finishing device and a hydraulic table 6, and the inner hole finishing device includes a hydraulic head 2, a clamp 5 and steel balls 3. The inner hole finishing device is installed on the working surface of the hydraulic table 6; the hydraulic head 2 is installed in the middle of the hydraulic machine 1, corresponding to the inner hole finishing device, and the stamping end is an arc concave inward , coincides with the radian of the surface of the steel ball 3; the clamp 5 is a hollow concave shape, which is conducive to the placement of the workpiece 4 and the extrusion work of the steel ball 3; the steel ball 3 is placed on the inner hole of the workpiece 4, Stamping by the hydraulic head 2; the inside of the hydraulic table 6 is equipped with a hydraulic gauge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com