Performing sound insulation rubber block and mounting method thereof

A technology of pre-forming and sound-insulating glue, which is applied in transportation, packaging, and vehicle parts, etc. It can solve the problems of poor electrophoretic effect in the cavity, easy blocking of electrophoretic fluid, and falling into the cavity, etc., and achieves excellent sound insulation effect and easy installation The process is simple and the effect of consistency is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

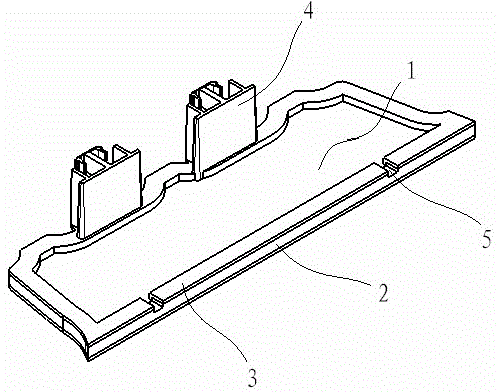

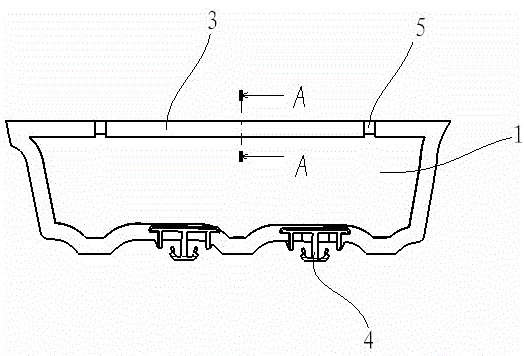

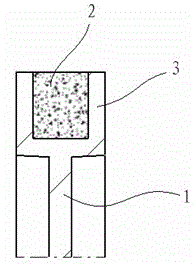

[0027] Such as Figure 1~5 As shown, the preformed sound-insulating rubber block of this embodiment includes a bracket body 1 made of toughened nylon material and a thermally expandable sealing material 2 made of EVA. The bracket body 1 is surrounded by a support groove 3 with the opening direction facing outward. The heat-expandable sealing material 2 is set in the support groove 3 ; the bracket body 1 is provided with a buckle 4 for connecting with the body sheet metal, and the buckle 4 protrudes from the outside of the bracket body 1 .

[0028] The upper groove wall of the support groove 3 is provided with several notches 5 , and the thermal expansion sealing material 2 is provided with notches 5 at positions corresponding to the notches 5 of the groove wall. In this way, the electrophoretic liquid can smoothly flow along the gap 5 of the groove wall above the support groove 3, avoiding the accumulation of the electrophoretic liquid, and improving the electrophoretic effect...

Embodiment 2

[0036] Such as Figure 9 As shown, different from Embodiment 1, the top surface of the bracket body 1 of this embodiment is covered with a thermally expandable sealing material layer 7 that is flush with the groove wall above the support groove 3, and the bracket body 1 and the thermally expandable sealing material layer 7 There are several through holes 8 with the same position. In this way, the electrophoretic liquid can flow freely along the through hole 8, which improves the electrophoretic effect; the heat-expandable sealing material layer 7 not only closes the through hole 8 after being heated and expanded, but also further improves the sealing and sound insulation effects.

[0037] Other structures and installation methods of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com