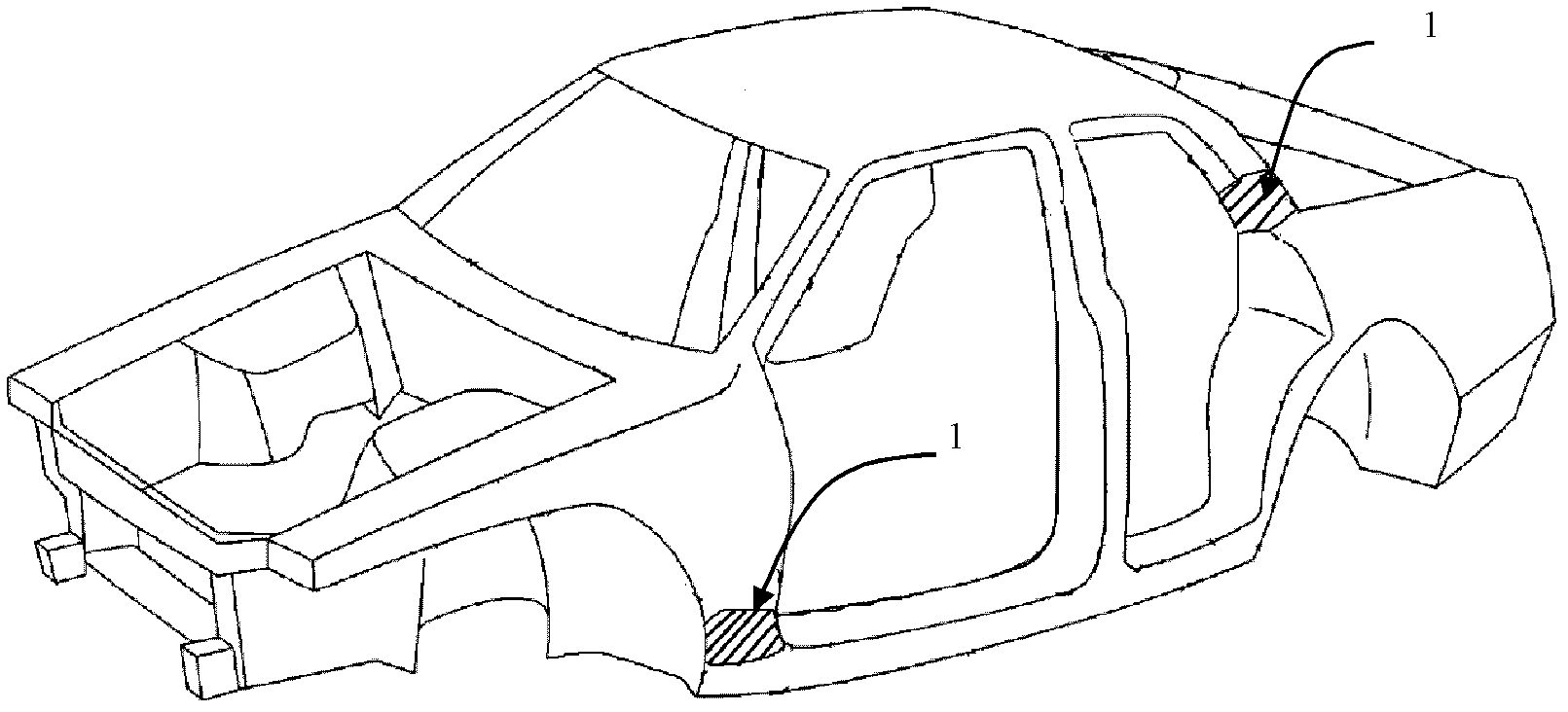

Preformed sound-insulation rubber block and installation method therefor

A technology of preforming and rubber blocks, which is applied in transportation, packaging, and vehicle parts, etc., to achieve the effects of NVH performance improvement, vibration isolation, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

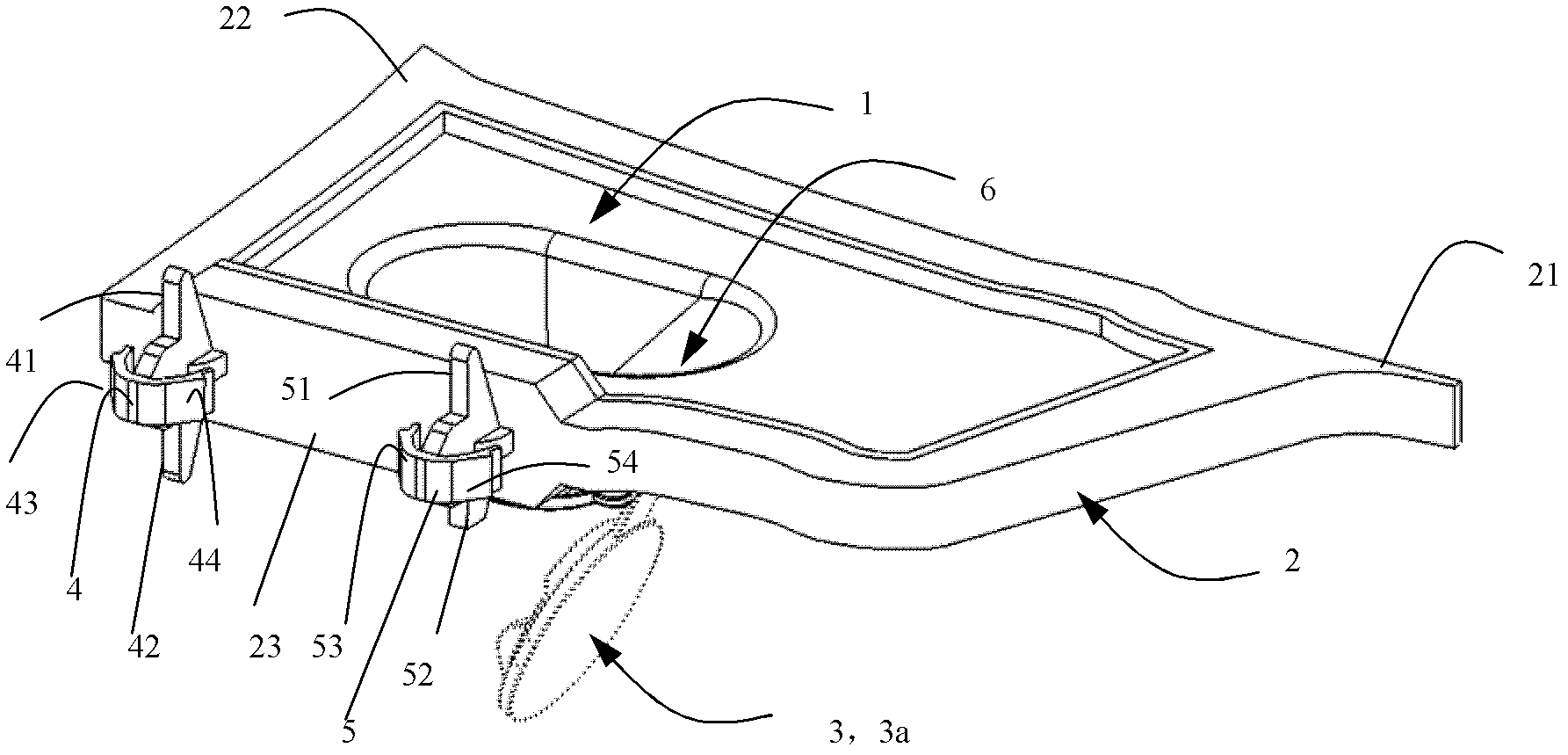

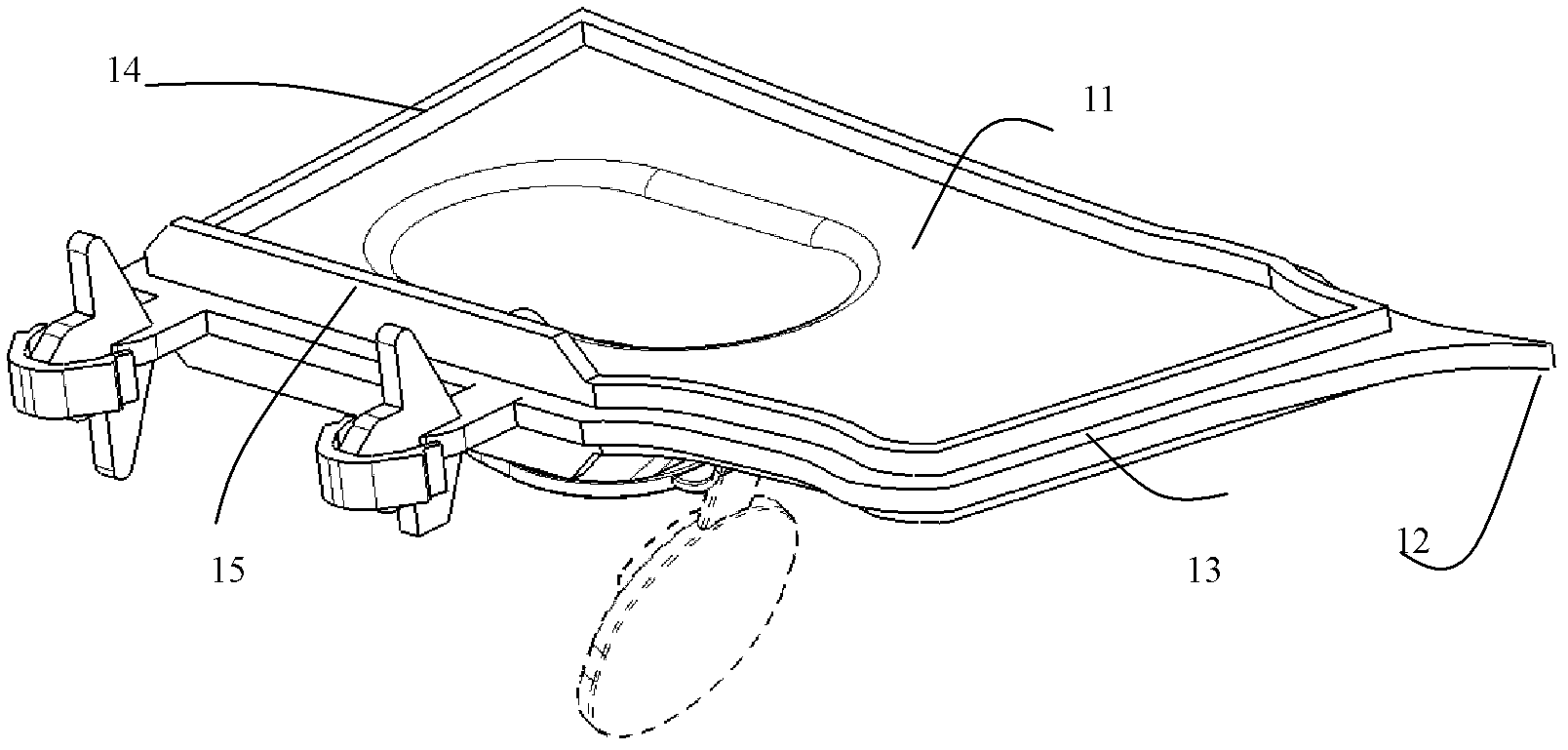

[0038] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

[0039] The sound-insulating rubber block in the automobile cavity provided by the present invention comprises a bracket body usually (nylon material) and a heat-expandable sealing material around the bracket body. The bracket body has two mounting buckles, which are fixed on the body panel gold on. In order to ensure the passability of the coating electrophoretic fluid, the distance between the foam layer and the sheet metal is 4-6mm, and the thermal expansion material is expanded through the coating electrophoretic oven to bond the carrier and the structural member wall, thereby sealing the entire cavity.

[0040] Two buckles are designed on the sound-proof rubber block, which can accurately fix the buckles on the sheet metal parts, prevent the rotation of the rubber block, and ensure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com