Compression stocking, compression stocking weaving process and seamless hosiery machine

A technology of compression socks and pressure, which is applied in the field of knitwear manufacturing, can solve problems such as insufficient pressure distribution, irregularities, and affecting the wearing effect of compression socks, and achieve the effect of improving the instability of pressure dosage and comfortable and scientific wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

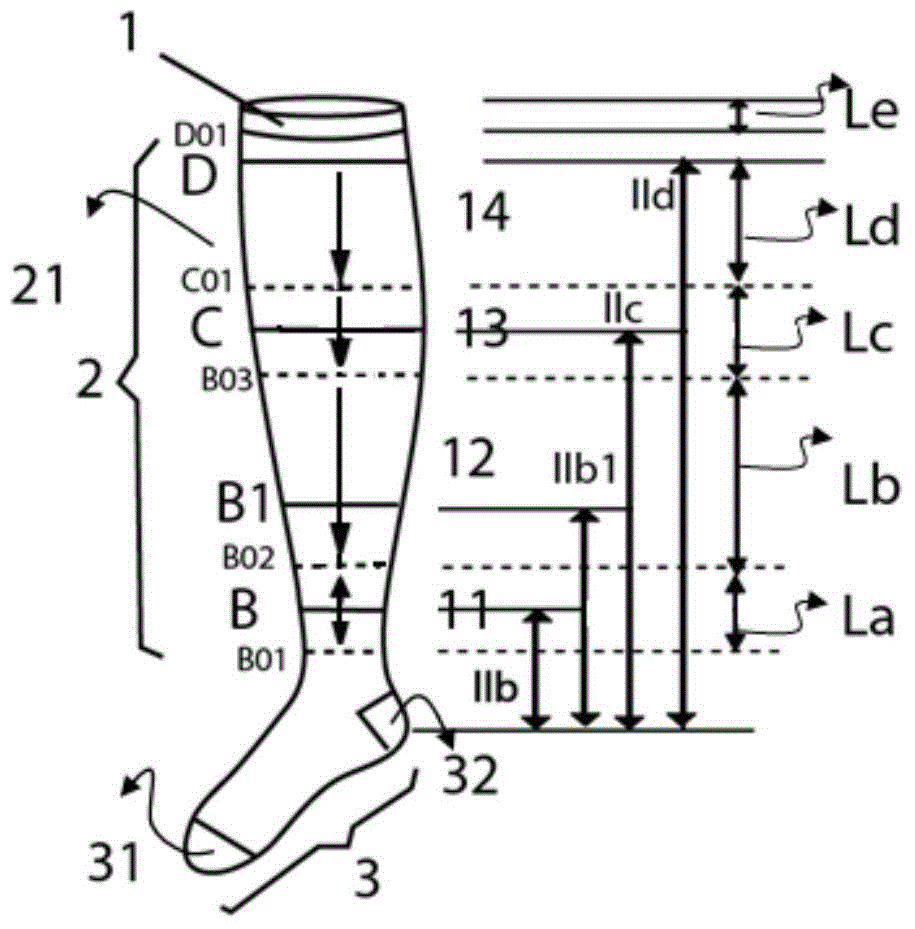

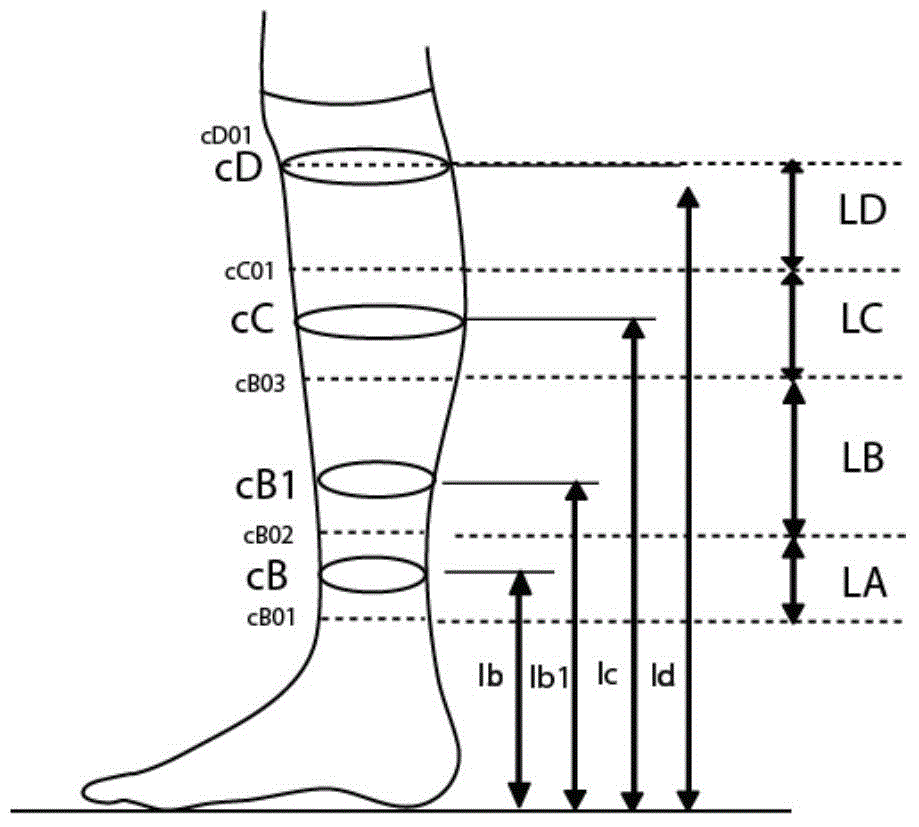

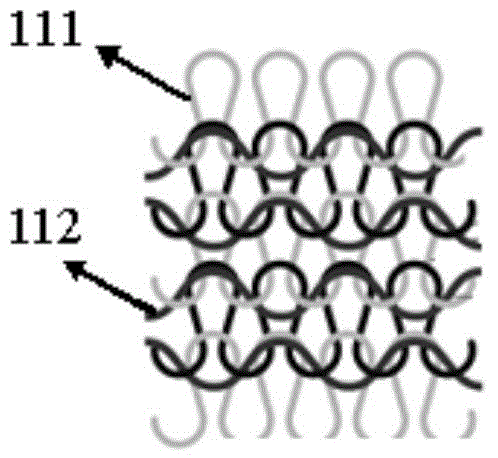

[0098] Apply the above preparation method, adjust the linear density of the elastic yarn, and coordinate with the parameter setting of the seamless circular hosiery machine (tube diameter, machine number, PYF active yarn feeding controller, stepping motor, knitting triangle, weaving row number, etc.), adjust the elasticity, tension, yarn feeding amount, knitting length, coil size and fabric density of the liner yarn to meet the needs of people with different body shapes and symptoms on the size, pressure distribution and pressure size of compression stockings .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com