Detachable helicopter landing platform

A technology for helicopters and platforms is applied in the field of detachable helicopter docking platforms, which can solve the problems of labor and time-consuming, the platform cannot be disassembled, and it is not conducive to the large-scale utilization of helicopters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

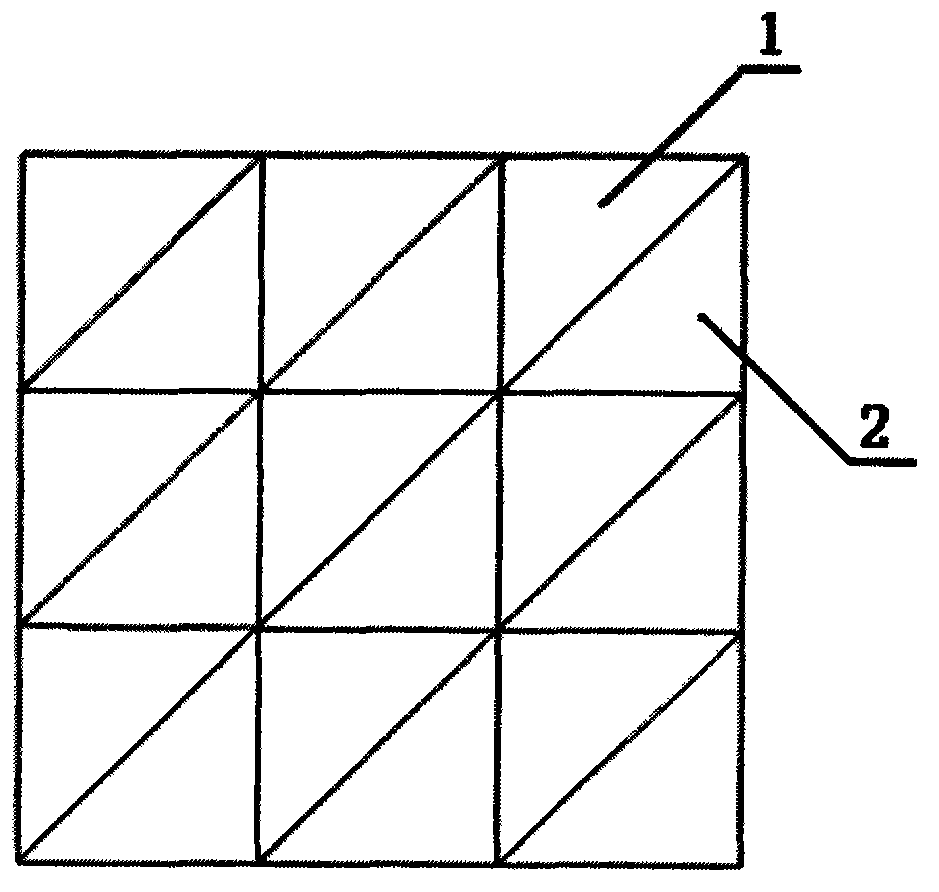

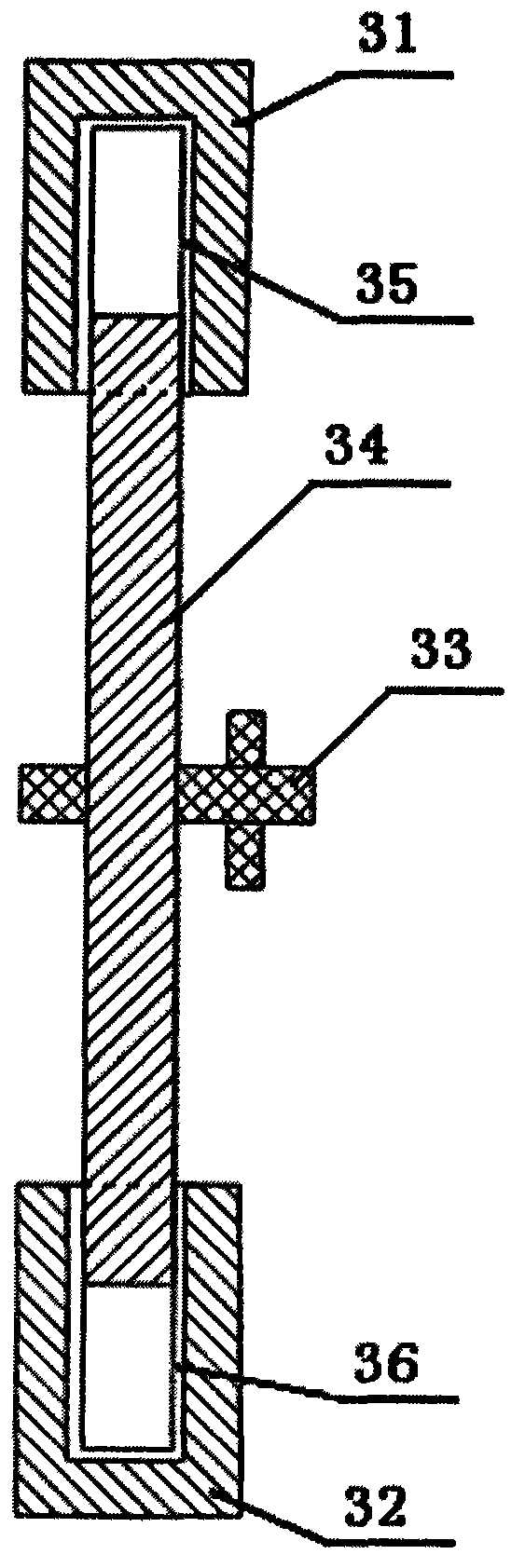

[0024] like figure 1 and Figure 4 As shown, the schematic diagram of the helicopter docking platform after the splicing of multiple substrates is completed, wherein any substrates are installed and spliced through the engaging grooves or protrusions on the sidelines, and the engaging grooves and protrusions are fixed by one or more Screws strengthen the fixation. For example, at the joint between the substrate 1 and the substrate 2, an engaging groove 4 is provided on the edge of the substrate 1, and a protrusion 5 is provided on the edge of the substrate 2. Through the engaging groove 4 of the substrate 1 and the connection between the substrate 2 The protrusion 5 is installed to splice the substrate 1 and the substrate 2; and so on. Of course, the invention is not limited thereto, and the splicing can be completed as long as the edge lines of two adjacent spliced substrates are respectively provided with engaging grooves and protrusions.

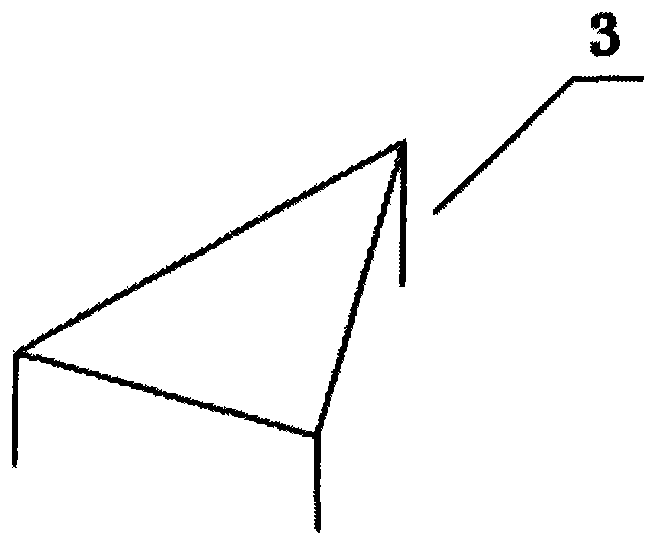

[0025] like figure 2 As sh...

Embodiment 2

[0035] like Figure 5 As shown, the lower supporting portion of the engaging groove 4 is provided with an installation angle θ. So that during installation, the protrusion 5 can be quickly extended into the groove with the help of other mechanical devices, and the position of the protrusion can be roughly fixed, and then the supporting legs can be further fine-tuned, and finally the protrusion can be fixed with screws. Through this design, splicing between substrates can be performed conveniently and quickly.

[0036] Further, the installation angle θ is preferably not greater than 5 degrees. In this way, even if there is a slight offset between the substrates, it can be ensured that the platform meets the plane requirements for the helicopter to dock, that is, the slope is not greater than 5 degrees.

[0037] The docking platform of the present invention has the advantages of simple structure, convenient installation and easy manufacture, and can realize docking of helicopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com