Non-reignition disconnector

A circuit breaker and reflashing technology, which is applied to high-voltage air circuit breakers, circuits, electrical components, etc., can solve problems such as temporary solutions but not root causes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

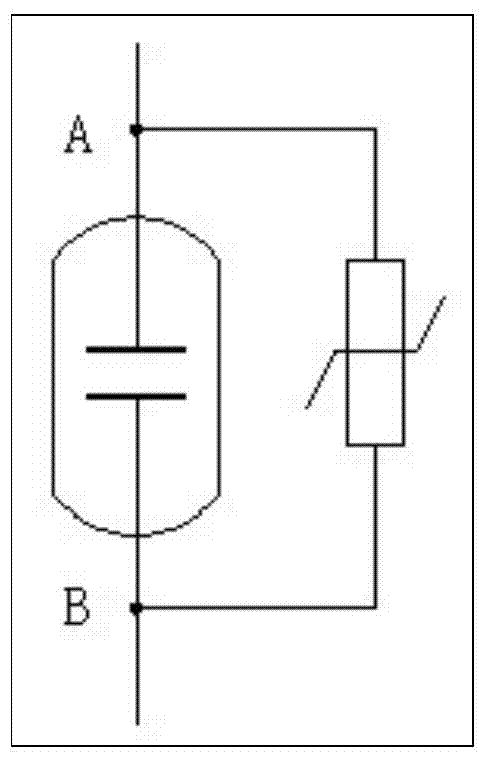

[0021] The invention patent proposes a non-refiring circuit breaker. The fundamental idea to solve this problem is that the reverse voltage appears on the fracture, and before the recovery voltage exceeds the withstand voltage level of the fracture, the voltage difference between the two ends of the fracture must be leveled. In other words, before re-ignition occurs, a leakage bypass is connected in parallel to the fracture to lower the voltage difference and destroy its re-ignition conditions, so that re-ignition can be prevented with half the effort. This requires the completion of the following process in a very short time when the fracture is disconnected: the contacts of the circuit breaker start to separate→detect the voltage between the two contacts→trigger and start the bypass device→the bypass device acts to bypass the fracture→ The bypass circuit discharges and reduces the recovery voltage of the fracture to below the withstand voltage level → the circuit breaker comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com