Enamelled rectangular wire painting assembling die and enamelled rectangular wire painting method

A technology of combining molds and enameled flat wires, applied in the direction of insulating conductors/cables, etc., can solve problems such as the performance of enameled flat wires not reaching the best state, heat loss in the furnace, and eccentricity of the paint film, so as to optimize the enamelled wire. The effect of flat wire performance, reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

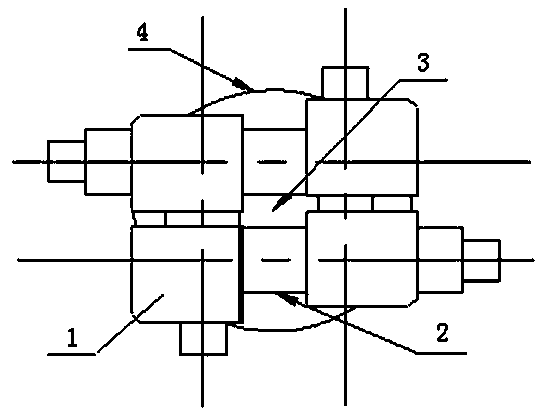

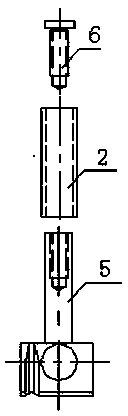

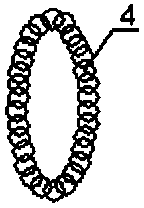

[0016] An enamelled flat wire painting combination mold is composed of the same four molds 1, and the four molds form a rectangle; each mold includes a fixed adjustment rod 5, a rolling sleeve 2 and a bolt 6, and the rolling sleeve is set by the bolt On the axis of the fixed adjustment rod, the surface of the rolling sleeve is threaded and rotates on the fixed adjustment rod; two adjacent molds are connected together by the fixed adjustment rod, and the rolling sleeves on the fixed adjustment rod form four rectangular side; the fixed adjustment rod is set on the spring coil 4, the channel of the conductor is a rectangular channel after the combined mold is opened, the conductor 3 passes through the center of the rectangular channel and the spring coil, and the combined mold relies on the tension of the spring coil to attach to the surface of the conductor, relyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com