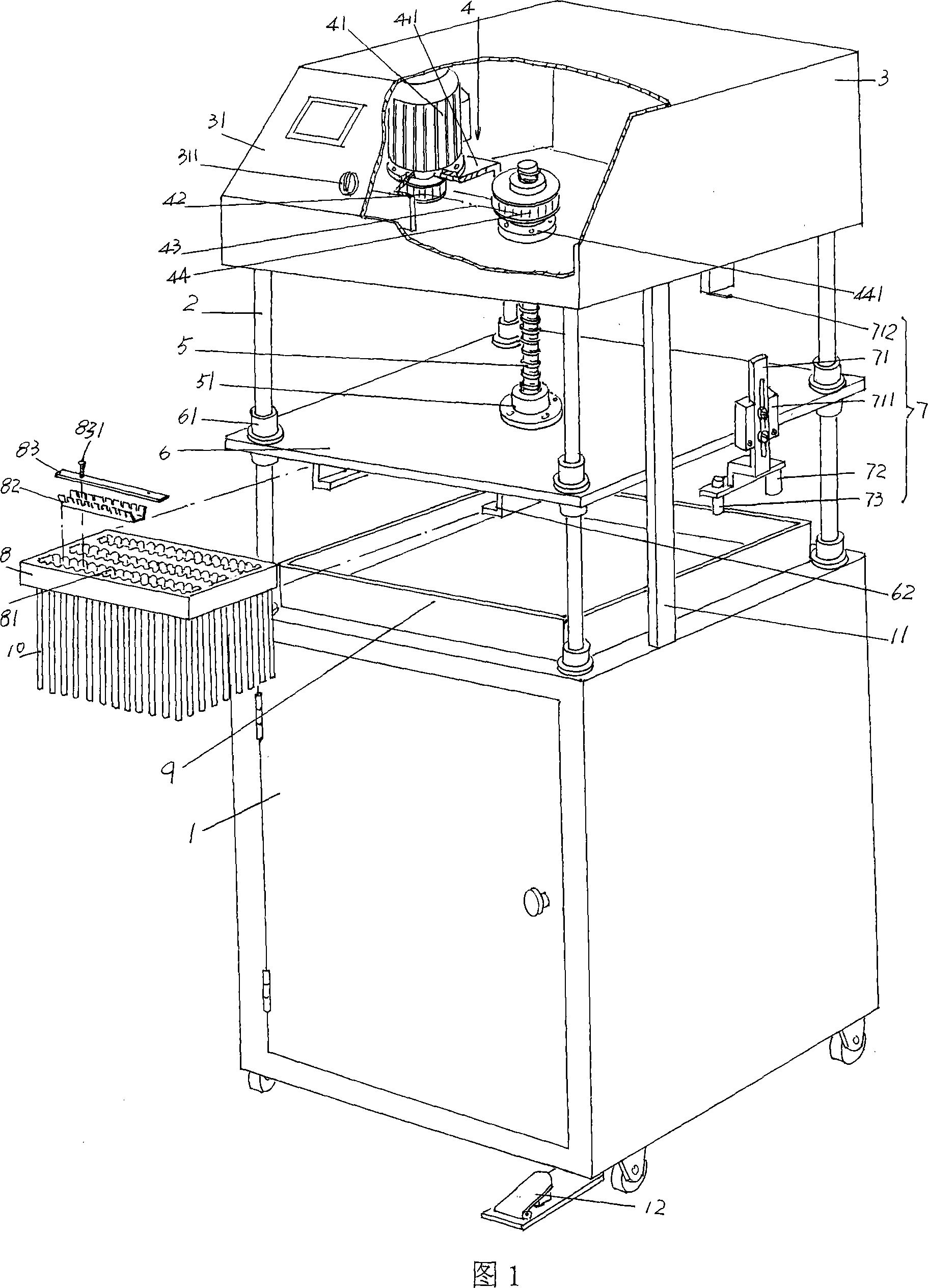

Automatic pencil paint dipping machine

An automatic and pencil technology, used in non-moving pencils, printing, writing utensils, etc., can solve problems such as affecting viewing, splattering materials, waste, etc., and achieve the effect of consistent amount of dipping paint, environmental protection, and excellent appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

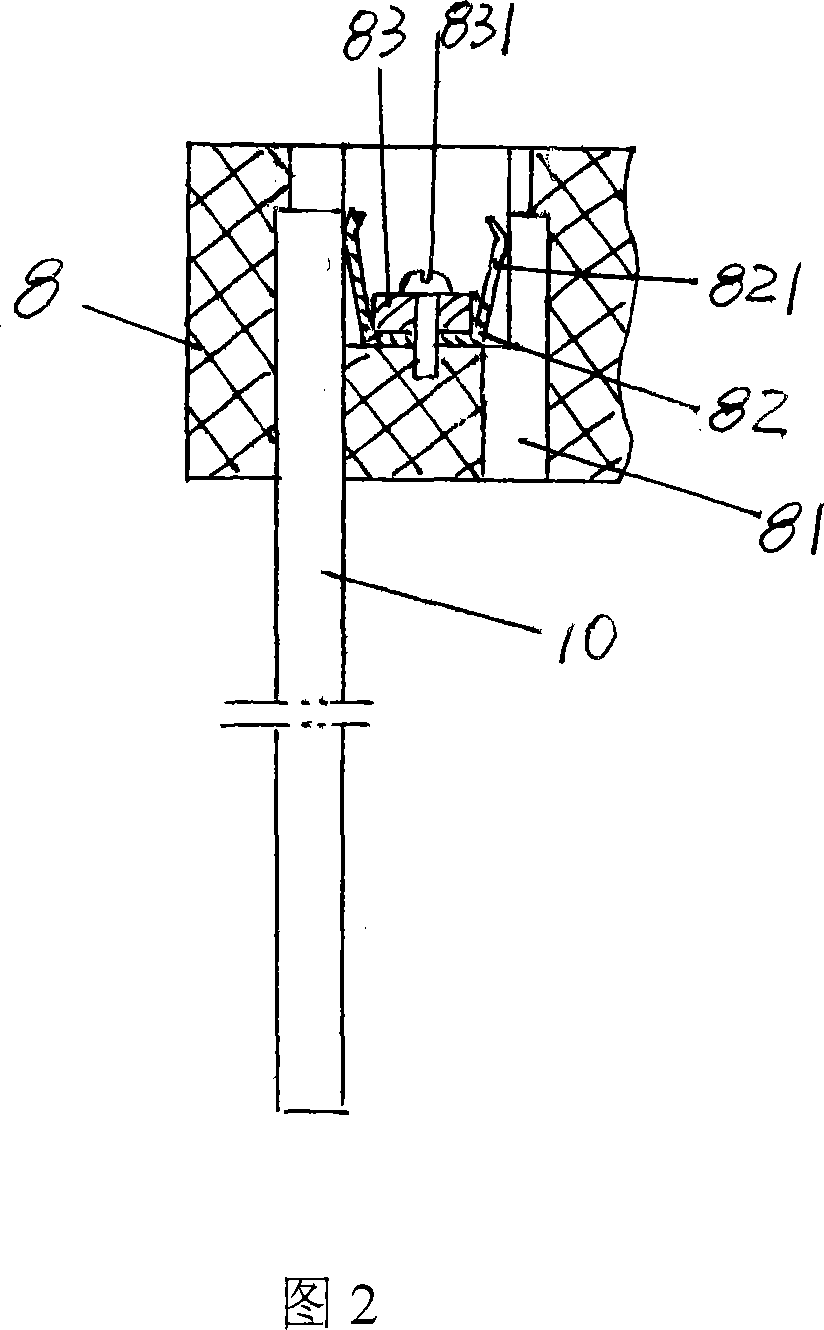

[0018] In Fig. 1, the electrical control box 1 with the PLC integrated block inside is generally in the shape of a rectangular cabinet. For the PLC integrated block, the model XC3 produced and sold by Xinjie Electronics Co., Ltd., Wuxi City, Jiangsu Province, China is preferably used. -14RT-E integrated block. A group of guide rods 2 can also be called guide posts, and are vertically fixed on the four corners of the top of the electrical control box 1 . On any side of the electrical control box 1, there is an electrical conduit 11 vertically. The electrical conduit 11 can be circular or rectangular. The lumen of the electrical conduit 11 is used for transitioning electrical circuits. A corner of the bottom of the electric control box 1 is provided with a pedal switch 12, which is used to control the operation of the transmission mechanism 4 to be mentioned below. Transmission box 3 is fixed on the top of guide bar 2, and it has operation panel 31, and operation panel 31 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com