Infrared shielding film, method for producing infrared shielding film, and infrared shield

A technology of infrared shielding and manufacturing method, applied in optical components, instruments, optics, etc., can solve problems such as difficulty in large-scale cost, reduced visible light transmittance of infrared shielding, and many layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

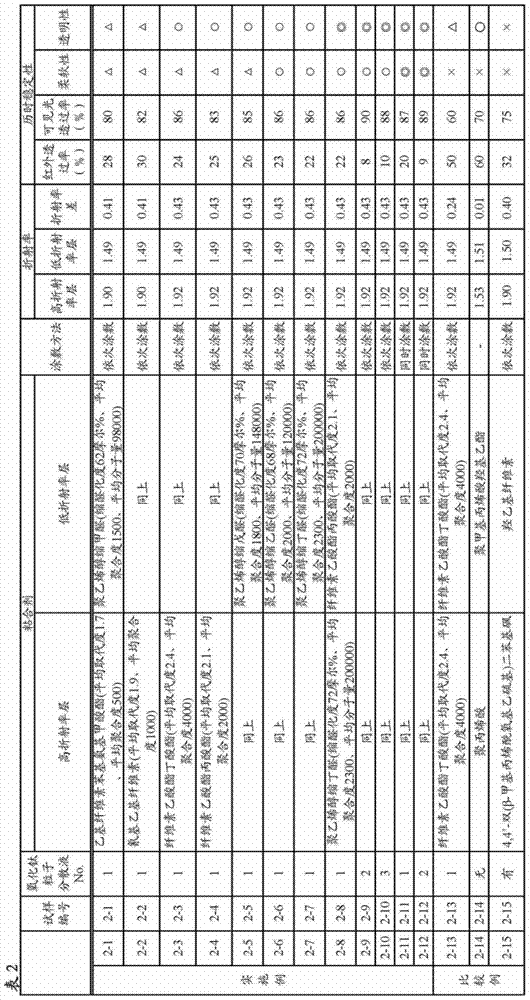

[0225]

[0226] The method for preparing the coating liquid for the high refractive index layer and the coating liquid for the low refractive index layer is not particularly limited, and examples thereof include adding temperature-responsive polymers, cellulose compounds, polyvinyl acetal resins, and metal oxides. Particles and other additives are added as needed, and the method of stirring and mixing. At this time, the order of adding the temperature-responsive polymer, cellulose compound or polyvinyl acetal resin, metal oxide particles, and other additives added as needed is not particularly limited, and each component may be sequentially added and mixed while stirring. Mixing can be done by adding all at once while stirring. If necessary, a solvent may be further used to obtain an appropriate viscosity.

[0227]

[0228] The viscosity of the high-refractive index layer coating solution and the low-refractive index layer coating solution at 25°C when performing simultan...

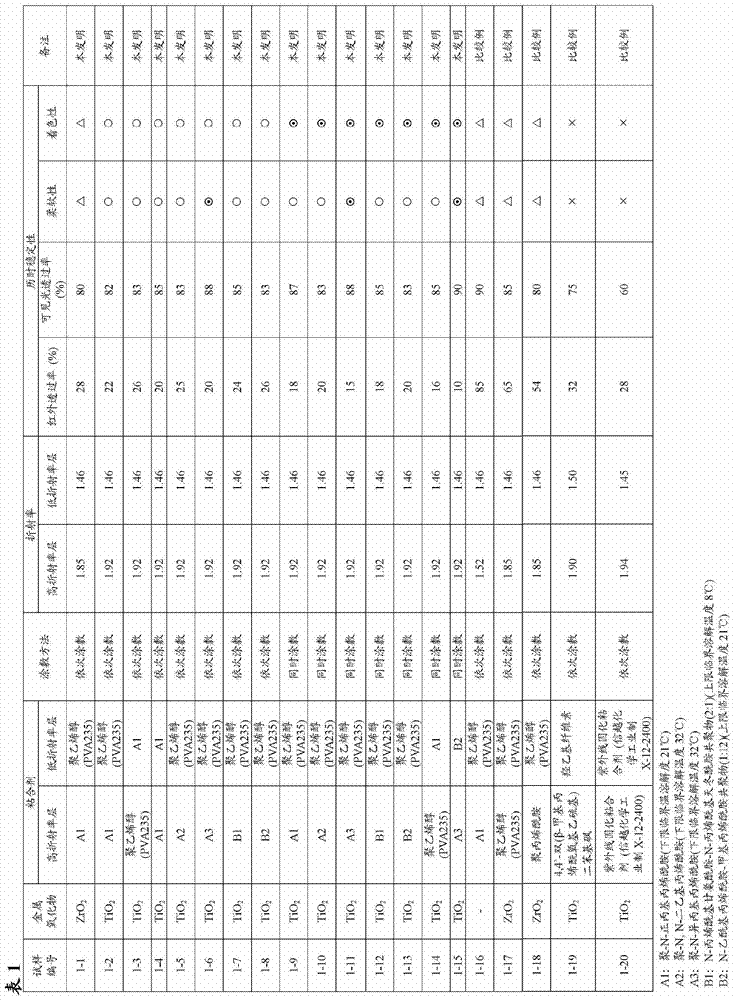

Embodiment I-1

[0249] "The Production of Infrared Shielding Film"

[0250] [Production of sample 1-1]

[0251] (Preparation of Coating Liquid for High Refractive Index Layer)

[0252] The following additives (1) to (4) were sequentially added and mixed to prepare a coating liquid for a high refractive index layer. In addition, poly-N-n-propyl acrylamide of PNIPAM (weight average molecular weight 19,000-26,000) manufactured by Sigma Aldrich Japan Co., Ltd. was used as poly-N-n-propyl acrylamide.

[0253] (1) 30 g of 30 mass % zirconia particle sol (volume average particle diameter 10 nm)

[0254] (2) 200 g of 5.0 mass % poly-N-n-propylacrylamide aqueous solution (lower limit critical solution temperature 21° C.)

[0255] (3) Pure water 150g

[0256] (4) 0.45 g of 5.0 mass % surfactant aqueous solutions (Nissan cation 2-DB-500E, quaternary ammonium salt cationic surfactant, manufactured by NOF Corporation).

[0257] (Preparation of Low Refractive Index Layer Coating Liquid)

[0258] The fo...

Embodiment I-2

[0358] [Production of near-infrared reflectors 1-1 to 1-15]

[0359] Near-infrared reflectors 1-1 to 1-15 were produced using the infrared shielding films of samples 1-1 to 1-15 produced in Example I-1. The infrared shielding films of samples 1-1 to 1-15 were respectively bonded to transparent acrylic resin plates with a thickness of 5 mm and 20 cm×20 cm with acrylic adhesives to produce near infrared reflectors 1-1 to 1-15.

[0360] [Evaluation]

[0361] With respect to the near-infrared reflectors 1-1 to 1-15 of the present invention prepared above, although the size of the near-infrared reflectors is large, they can be easily used. In addition, by using the infrared shielding film of the present invention, it can be confirmed that excellent near-infrared reflectivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com