Header crop clamping height adjustment device for half-feed harvester

A technology for height adjustment devices and harvesters, which is applied to harvesters, agricultural machinery and implements, threshing equipment, etc., can solve problems such as production loss, bulky transmission structure, and restrictions on the miniaturization of half-feed combine harvesters, and achieve manufacturing The effect of low cost, simplified header structure, and ingenious design of transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

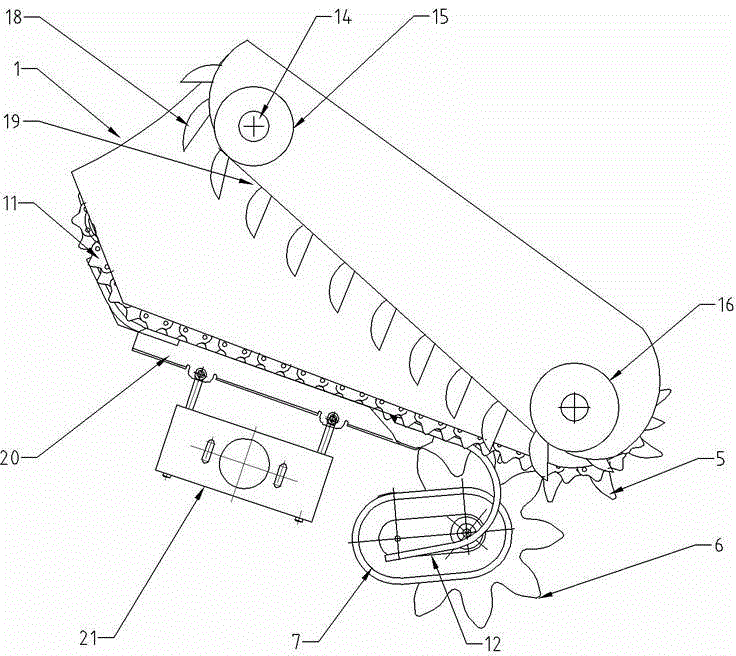

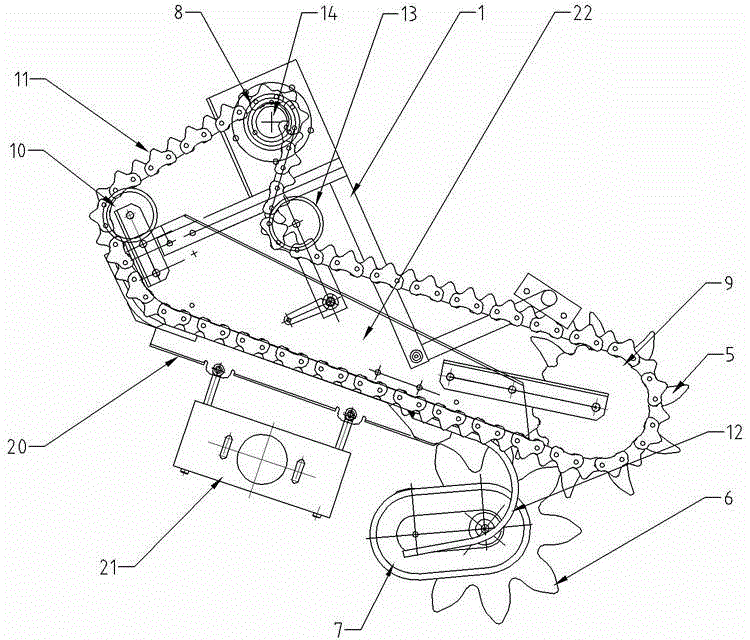

[0018] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

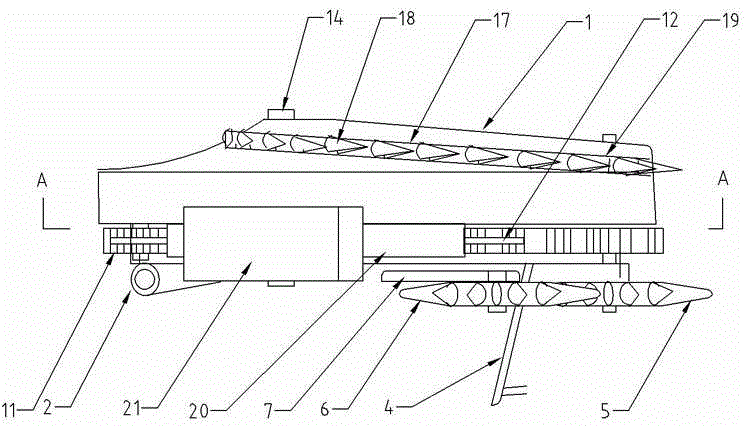

[0019] Reference attached figure 1 It is a header clamping height adjustment device for a half-feed harvester, including a frame 1 and lower, middle, and upper three-layer transmission and delivery components on the frame; the frame 1 is installed on the header crop collecting and conveying device and Horizontally arranged between the clamping chain mechanisms for transporting threshing; there is a cantilever rod 2 fixed to the frame at the bottom of the rear end of the frame 1, and the cantilever rod 2 is movable in the cantilever tube 3 of the harvesting fuselage, so that the entire frame 1 can Rotate around the cantilever tube 3; at the bottom of the front end of the frame 1, there is an adjustment rod 4 that can adjust the inclination angle of the frame 1 up and down.

[0020] attached figure 2 The upper stratum on the frame 1 is made up of upper driving sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com