Structure of hydraulic machine material ejection mechanism

A jacking mechanism and hydraulic press technology, applied in the field of hydraulic presses, can solve problems such as increased stroke resistance, easy breakage, and easy wear, and achieve the effects of increased stroke resistance, easy breakage, and easy wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

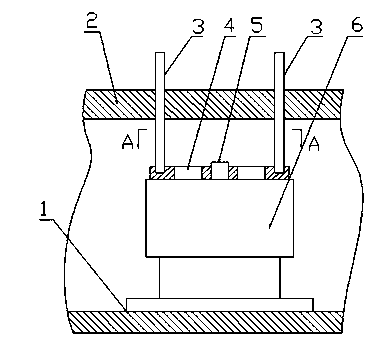

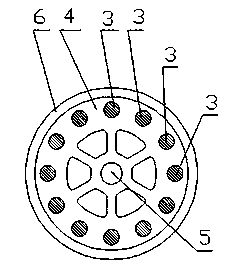

[0009] combined with figure 1 , figure 2 , the specific embodiment of the present invention is:

[0010] The structure of a hydraulic machine jacking mechanism according to the present invention is composed of: machine base (1), machine table (2), ejector rod (3), positioning disc (4), positioning shaft (5), hydraulic The pad (6) is composed of a hydraulic pad (6), which is characterized in that a hydraulic pad (6) is fixed in the space between the machine base (1) and the machine table (2), and the center of the hydraulic pad (6) is fixed A positioning shaft (5), a positioning disc (4) is arranged on the upper surface of the movable cylinder of the hydraulic pad (6), the positioning shaft (5) passes through the middle hole of the positioning disc (4) and is combined with the positioning disc (4), The upper plane of the positioning disc (4) is formed with blind holes in the circumference division, and the machine tool table (2) directly above the blind holes is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com