An automobile battery fixing bracket assembly

A technology for fixing brackets and batteries, applied in vehicle components, circuits or fluid pipelines, transportation and packaging, etc., can solve the problems of small installation space and low rigidity, and achieve the effect of solving small space and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

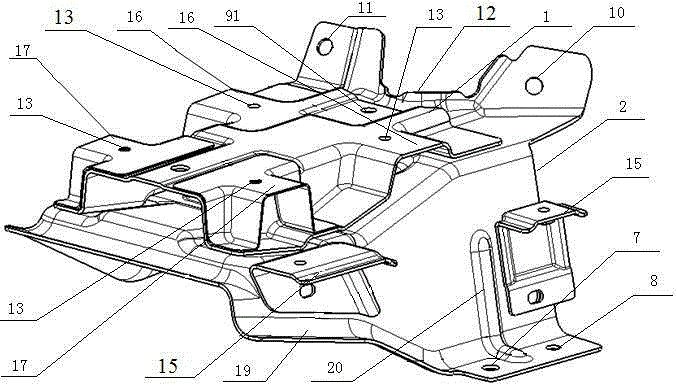

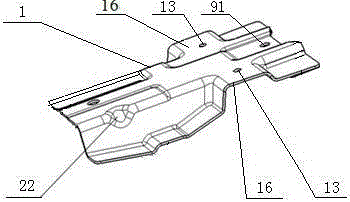

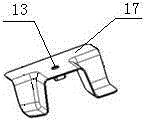

[0028] see Figure 1-8 A car battery fixing bracket assembly shown includes a lower bracket 2 and an upper bracket 1, and is characterized in that:

[0029] The cross-section of the lower bracket 2 is in the shape of "Ji", and the top of the lower bracket 2 is a slope inclined to the left. This design can ensure that the Z-direction height of the lower bracket is the smallest, and a transverse reinforcing rib 18 is arranged in the middle of the slope , a first installation hole 9 is provided on the right side of the transverse reinforcing rib; a flange 19 is respectively provided on the front and rear edges of the lower bracket 2, and the design of the transverse reinforcing rib and the flange is enhanced To ensure the overall rigidity of the structure, a second mounting hole 7 and a third mounting hole 8 are respectively provided on the flanges of the front side and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com