A kind of all-organic hard water stable engine coolant and its preparation method

A technology of engine coolant and hard water stabilizer, which is applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of poor stability of all-organic type coolant and the inability to meet the requirements of hard water stability of coolant, etc. Achieve the effect of maintaining the stability of hard water and improving the stability of hard water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment, the present invention will be further described:

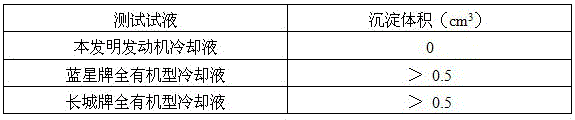

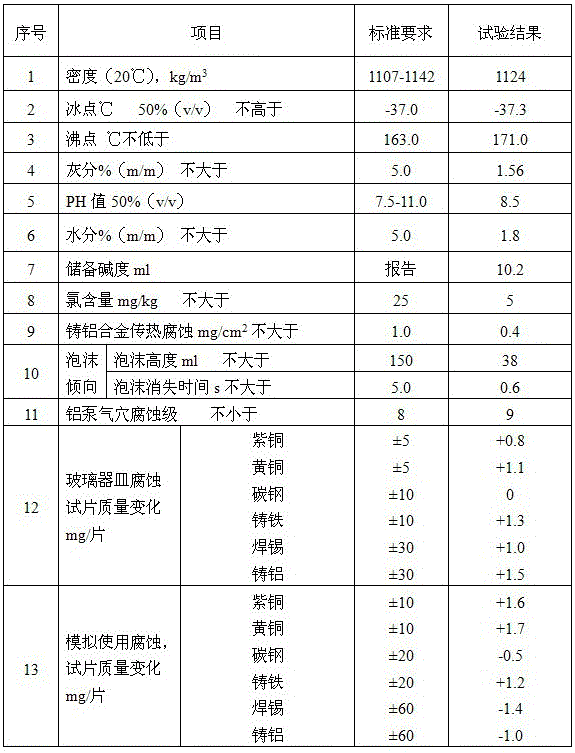

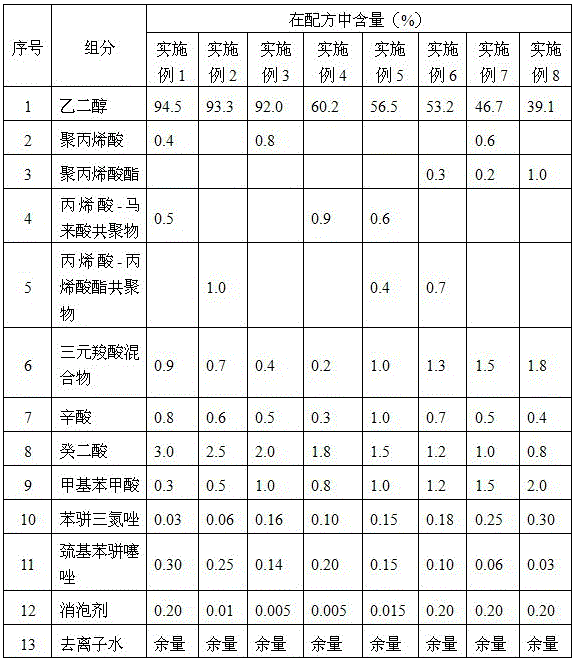

[0029] The formula of the engine coolant of the invention has been subjected to a large number of screening experiments, and a formula combination with reasonable economy and excellent technology has been obtained. The specific components and ratios of the embodiments are shown in Table 1.

[0030] Table 1 Components and proportions of all organic engine coolant

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com