A method for simultaneously recovering neodymium, praseodymium, dysprosium, cobalt, and iron from NdFeB sludge under CO3-OH system

A CO3-OH, NdFeB technology, applied in the field of praseodymium, cobalt, dysprosium, iron, and extraction of neodymium, can solve the problems of waste of rare earth resources and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

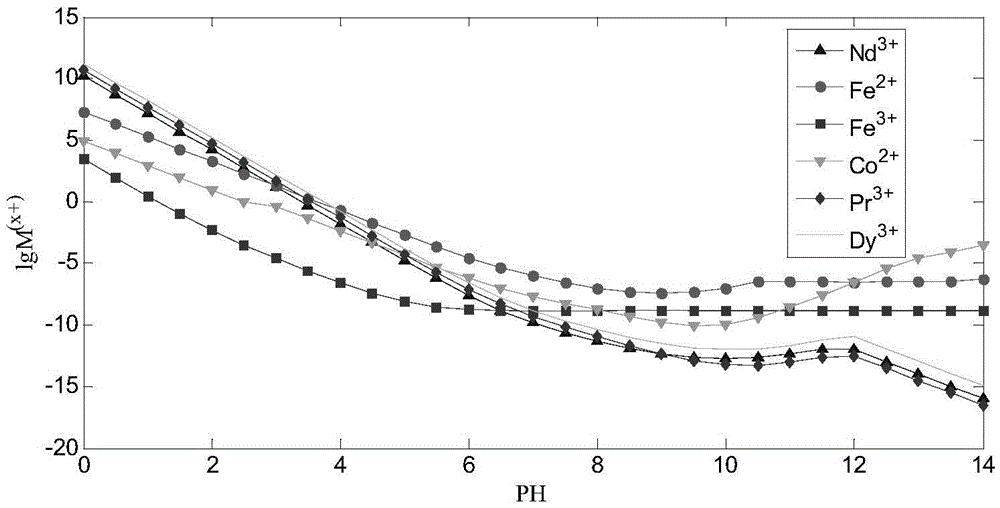

[0071] Table 1 "CO 3 The main chemical reactions and equilibrium constants involved in the -OH" system

[0072] No.

Reactions

logK

No.

Reactions

logK

1

h 2 O=H + +OH —

logK w =-14

16

Nd+OH — =Nd(OH) 2+

logK nh =5.5

2

co 2+ +OH — =Co(OH) +

logK ch1 =3.3

17

Pr+OH — =Pr(OH) 2+

logK pH =4.3

3

co 2+ +2OH — =Co(OH) 2 0

logK ch2 =9.2

18

Dy+OH — =Dy(OH) 2+

logK dh =5.2

4

co 2+ +3OH — =Co(OH) 3 —

logK ch3 =10.5

19

Co(OH) 2 (s)=Co 2+ +2OH —

logKspch=-14.23

5

co 2+ +4OH — =Co(OH) 4 2-

logK ch4 =10.2

20

Fe(OH) 2 (s)=Fe 2+ +2OH —

logKspf2h=-16.31

6

2Co 2+ +OH — =Co 2 (OH) 3+

logK ch21 =2.7

21

Fe(OH) 3 (s)=Fe 3+ +3OH —

logKspf3h=-38.55

7

4Co 2+ +4OH — =Co 4 (OH) 4 4+

logK ch44 =25.6

2...

Embodiment 2

[0127] Table 1 "CO 3 The main chemical reactions and equilibrium constants involved in the -OH" system

[0128] No.

Reactions

logK

No.

Reactions

logK

1

h 2 O=H + +OH —

logK w =-14

15

Nd+OH — =Nd(OH) 2+

logK nh =5.5

2

co 2+ +OH — =Co(OH) +

logK ch1 =3.3

16

Pr+OH — =Pr(OH) 2+

logK pH =4.3

[0129] 3

co 2+ +2OH — =Co(OH) 2 0

logK ch2 =9.2

17

Dy+OH — =Dy(OH) 2+

logK dh =5.2

4

co 2+ +3OH — =Co(OH) 3 —

logK ch3 =10.5

18

Co(OH) 2 (s)=Co 2+ +2OH —

logKspch=-14.23

5

co 2+ +4OH — =Co(OH) 4 2-

logK ch4 =10.2

19

Fe(OH) 2 (s)=Fe 2+ +2OH —

logKspf2h=-16.31

6

2Co 2+ +OH — =Co 2 (OH) 3+

logK ch21 =2.7

20

Fe(OH) 3 (s)=Fe 3+ +3OH —

logKspf3h=-38.55

6 --> 7

4Co 2+ +4OH — =Co 4 (OH) 4 4+

...

Embodiment 3

[0133] Table 1 "CO 3 The main chemical reactions and equilibrium constants involved in the -OH" system

[0134] No.

Reactions

logK

No.

Reactions

logK

1

h 2 O=H + +OH —

logK w =-14

16

Nd+OH — =Nd(OH) 2+

logK nh =5.5

2

co 2+ +OH — =Co(OH) +

logK ch1 =3.3

17

Pr+OH — =Pr(OH) 2+

logK p H=4.3

3

co 2+ +2OH — =Co(OH) 2 0

logK ch2 =9.2

18

Dy+OH — =Dy(OH) 2+

logK dh =5.2

4

co 2+ +3OH — =Co(OH) 3 —

logK ch3 =10.5

19

Co(OH) 2 (s)=Co 2+ +2OH —

logKspch=-14.23

5

co 2+ +4OH — =Co(OH) 4 2-

logK ch4 =10.2

20

Fe(OH) 2 (s)=Fe 2+ +2OH —

logKspf2h=-16.31

6

2Co 2+ +OH — =Co 2 (OH) 3+

logK ch21 =2.7

21

Fe(OH) 3 (s)=Fe 3+ +3OH —

logKspf3h=-38.55

7

4Co 2+ +4OH — =Co 4 (OH) 4 4+

logK ch44 =25.6

2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com