A method for simultaneously recovering neodymium, praseodymium, dysprosium, cobalt, and iron from NdFeB sludge under C2H2O4-NH3 system

A C2H2O4-NH3, C2H2O4 technology, applied in the direction of improving process efficiency, can solve problems such as environmental pollution and waste of rare earth resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

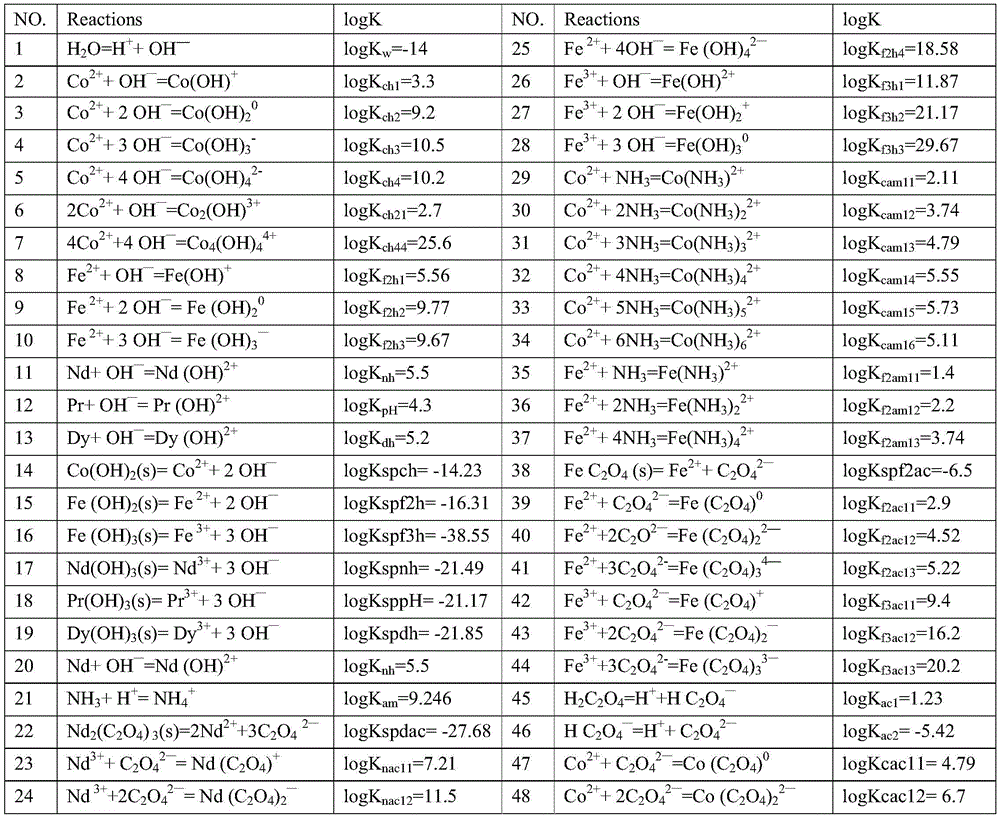

[0089] Table 1"C 2 h 2 o 4 The main chemical reactions and equilibrium constants involved in the -NH3" system

[0090] No.

Reactions

logK

No.

Reactions

logK

1

h 2 O=H + +OH —

logK w =-14

25

Fe 2+ +4OH — =Fe(OH) 4 2—

logK f2h4 =18.58

2

co 2+ +OH — =Co(OH) +

logK ch1 =3.3

26

Fe 3+ +OH — =Fe(OH) 2+

logK f3h1 =11.87

3

co 2+ +2OH — =Co(OH) 2 0

logK ch2 =9.2

27

Fe 3+ +2OH — =Fe(OH) 2 +

logK f3h2 =21.17

4

co 2+ +3OH — =Co(OH) 3 -

logK ch3 =10.5

28

Fe 3+ +3OH — =Fe(OH) 3 0

logK f3h3 =29.67

5

co 2+ +4OH — =Co(OH) 4 2-

logK ch4 =10.2

29

co 2+ +NH 3 =Co(NH 3 ) 2+

logK cam11 =2.11

6

2Co 2+ +OH — =Co 2 (OH) 3+

logK ch21 =2.7

30

co 2+ +2NH 3 =Co(NH 3 ) 2 2+

logK cam12 =3.74

7

4C...

Embodiment 2

[0162] Table 1"C 2 h 2 o 4 The main chemical reactions and equilibrium constants involved in the -NH3" system

[0163]

[0164]

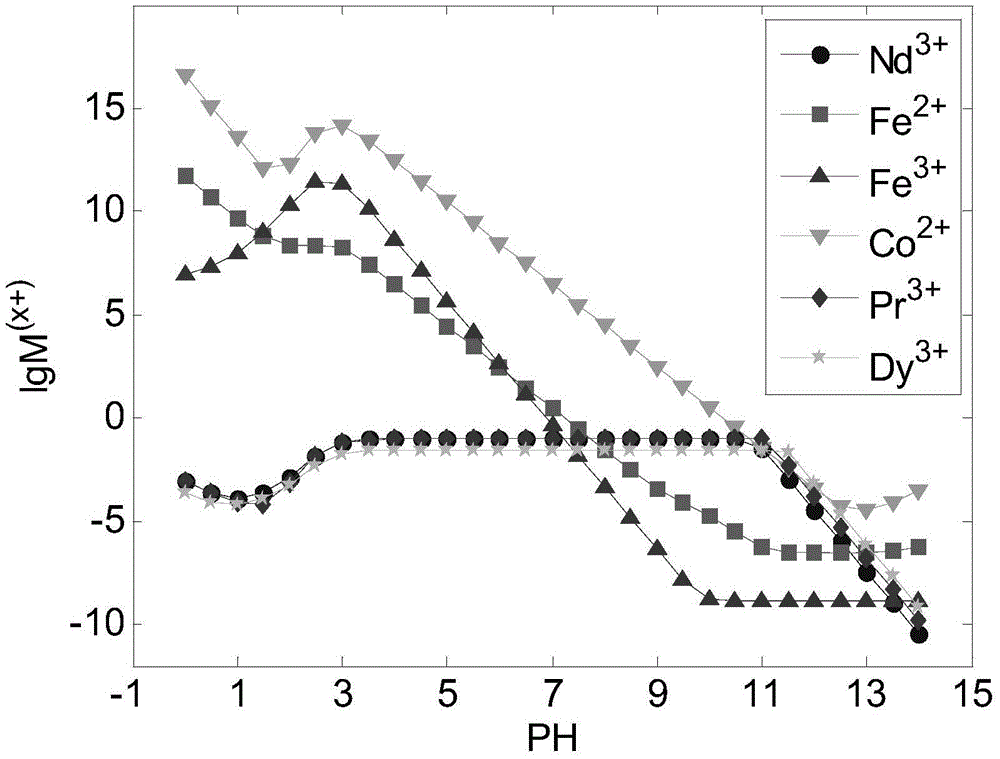

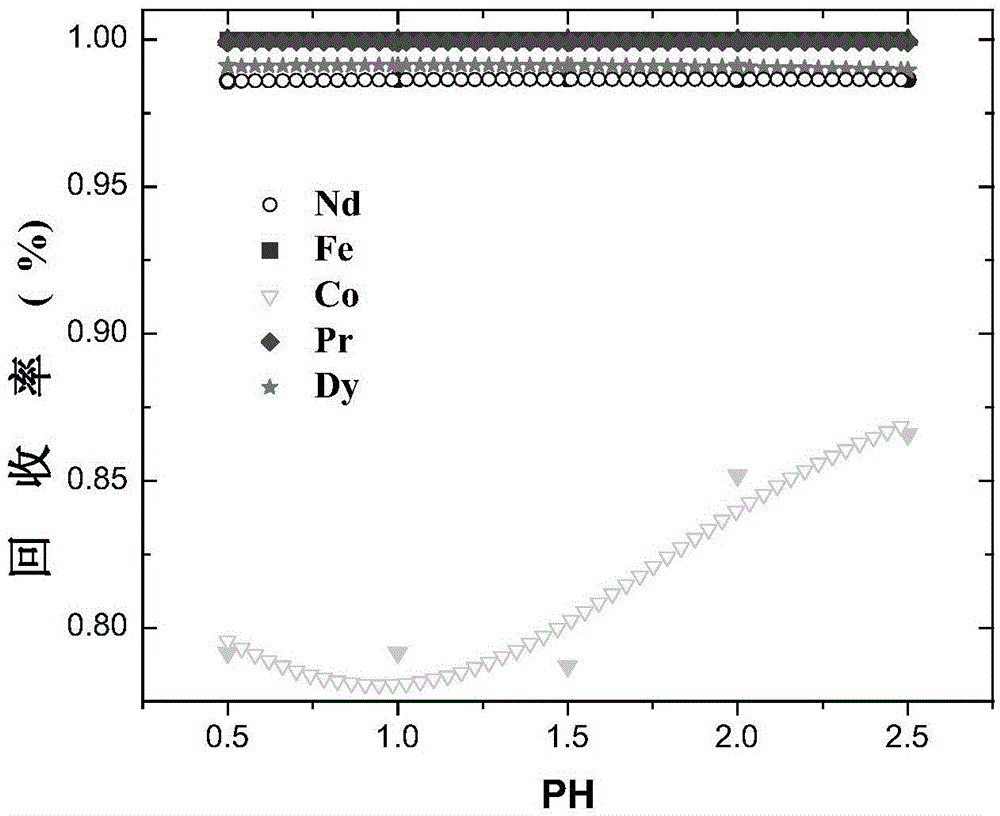

[0165] In the theoretical part: first, consult the 2 h 2 o 4 -NH 3 The possible reactions of neodymium, praseodymium, dysprosium, cobalt, and iron in the system and the equilibrium constants of each reaction are shown in Table 1. Established in C through chemical equilibrium, mass balance, and charge conservation 2 h 2 o 4 -NH 3 The thermodynamic model under the system, such as figure 1 shown. according to figure 1 , it can be considered that trivalent iron ions should be selected as far as possible, and it can be seen that the optimum recovery pH value of neodymium, praseodymium and dysprosium rare earth salt should be within 0.5~2.5, and the recovery of iron and cobalt should be at a high pH value. Therefore, The patented design process is completed by adjusting the pH twice. The pH range of the optimal precipitation of neodymiu...

Embodiment 3

[0168] Table 1"C 2 h 2 o 4 The main chemical reactions and equilibrium constants involved in the -NH3" system

[0169]

[0170]

[0171] In the theoretical part: first, consult the 2 h 2 o 4 -NH 3 The possible reactions of neodymium, praseodymium, dysprosium, cobalt, and iron in the system and the equilibrium constants of each reaction are shown in Table 1. Established in C through chemical equilibrium, mass balance, and charge conservation 2 h 2 o 4 -NH 3 The thermodynamic model under the system, such as figure 1 shown. according to figure 1 , it can be considered that trivalent iron ions should be selected as far as possible, and it can be seen that the optimum recovery pH value of neodymium, praseodymium and dysprosium rare earth salt should be within 0.5~2.5, and the recovery of iron and cobalt should be at a high pH value. Therefore, The patented design process is completed by adjusting the pH twice. The pH range of the optimal precipitation of neodymiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com