Weighing hydraulic control structure of large structures based on speed control

A large-scale structure and control structure technology, applied in the direction of lifting devices, etc., can solve problems such as economic losses, tipping, and platform slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

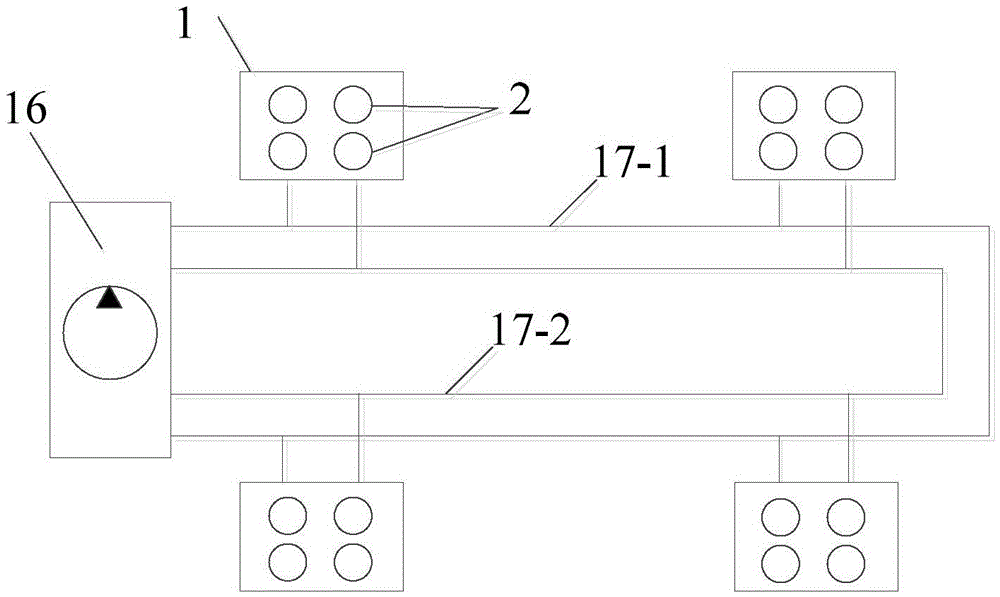

[0010] Such as figure 1 As shown, the oil supply oil passages and oil return oil passages 17 - 1 , 17 - 2 of the four jacking units 1 with the same structure of the present invention can be connected with one pump station 16 .

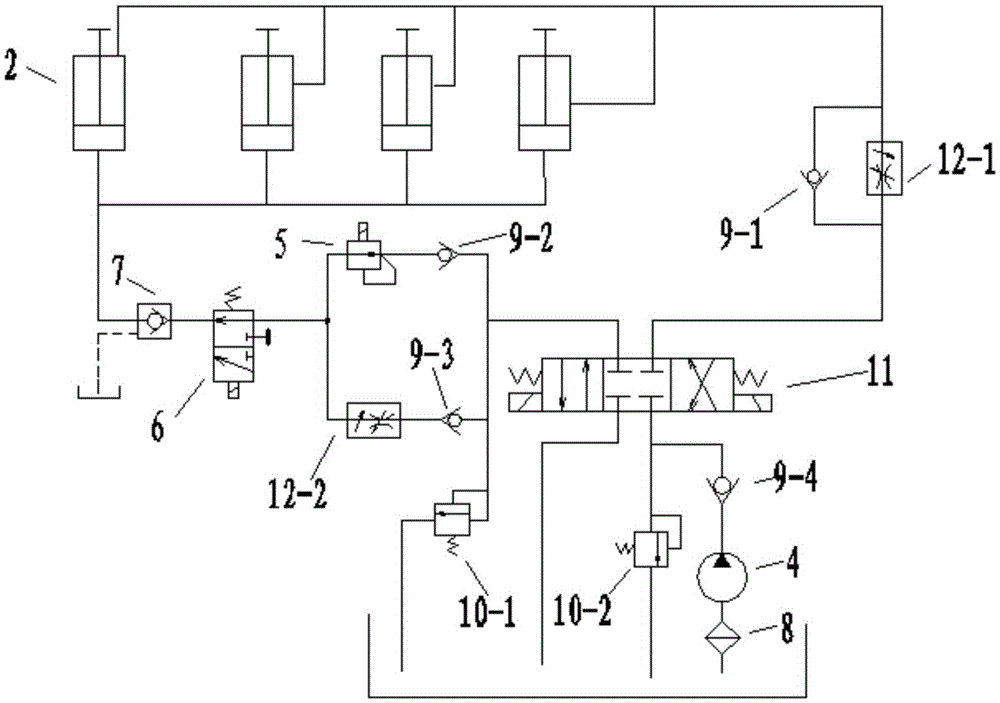

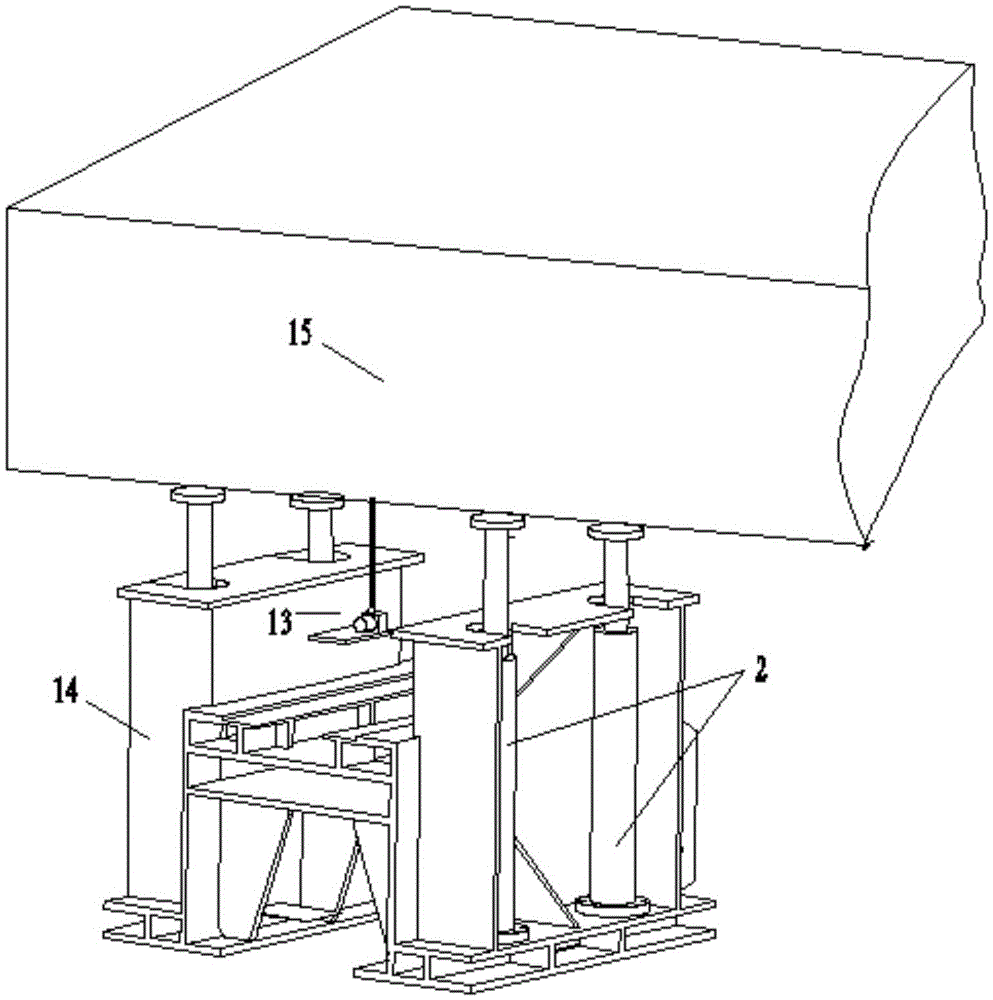

[0011] Such as Figure 2-3 The large-scale structure weighing hydraulic control structure based on speed regulation control shown in the present invention includes four jacking units 1 with the same structure, each jacking unit 1 is installed on a bracket 14, and each bracket 14 is equipped with a pull-wire displacement sensor 13, and the pull-wire end of the pull-wire displacement sensor 13 is connected to the large structure 15 installed on the four jacking units 1 to measure the jacking and descending displacement of each jacking unit 1, Four pull-wire displacement sensors 13 are connected with the programmable logi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com