A kind of photosensitive random copolymer honeycomb porous film and preparation method thereof

A technology of random copolymer and porous film, which is applied in the field of photosensitive random copolymer honeycomb porous film and its preparation, can solve the problems of single product type, harsh anionic polymerization reaction conditions, limited application of honeycomb porous film, etc. good sequence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

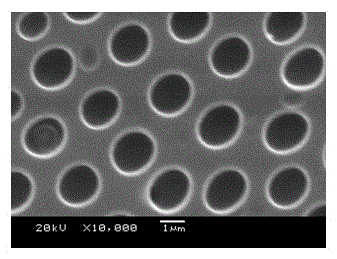

Image

Examples

Embodiment 1

[0027] The photosensitive random copolymer polystyrene-co-polymethacryloxyethyl cinnamate (PS-co-PCEMA) is composed of the following raw materials in parts by weight:

[0028] A component 1

[0029] Styrene 10

[0030] Azobisisobutyronitrile 0.03

[0031] 1,4 dioxane 10

[0032] Wherein: the weight fraction and proportioning of A component are as follows:

[0033] Hydroxyethyl methacrylate 1

[0034] Cinnamoyl Chloride 1.5

[0035] Triethylamine 1

[0036] Dichloromethane 7

[0037] The preparation method of the photosensitive random copolymer is as follows: mix the hydroxyethyl methacrylate, cinnamoyl chloride, triethylamine, and dichloromethane of the above-mentioned component A in proportion, stir evenly, and react in an ice-water bath for 24 hours. The product was sequentially washed with deionized water, saturated K 2 CO 3 solution and deionized water, distill the extract under reduced pressure below 40°C, add absolute ethanol to dissolve, recrystallize, and vacu...

Embodiment 2

[0043] The photosensitive random copolymer polystyrene-co-polymethacryloxyethyl cinnamate (PS-co-PCEMA) is composed of the following raw materials in parts by weight:

[0044] A component 1

[0045] Styrene 10

[0046] Azobisisobutyronitrile 0.025

[0047] 1,4 dioxane 10

[0048] Wherein: the weight fraction and proportioning of A component are as follows:

[0049] Hydroxyethyl methacrylate 1

[0050] Cinnamoyl Chloride 1.6

[0051] Triethylamine 1

[0052] Dichloromethane 8

[0053]The preparation method of the photosensitive random copolymer is as follows: mix the hydroxyethyl methacrylate, cinnamoyl chloride, triethylamine, and dichloromethane of the above-mentioned component A in proportion, stir evenly, and react in an ice-water bath for 24 hours. The product was sequentially washed with deionized water, saturated K 2 CO 3 solution and deionized water, distill the extract under reduced pressure below 40°C, add absolute ethanol to dissolve, recrystallize, and vacu...

Embodiment 3

[0058] A photosensitive random copolymer polystyrene-co-polymethacryloxyethyl cinnamate (PS-co-PCEMA), composed of the following raw materials in parts by weight:

[0059] A component 1

[0060] Styrene 12

[0061] Azobisisobutyronitrile 0.03

[0062] 1,4 dioxane 12

[0063] Wherein: the weight fraction and proportioning of A component are as follows:

[0064] Hydroxyethyl methacrylate 1

[0065] Cinnamoyl Chloride 1.7

[0066] Triethylamine 1

[0067] Dichloromethane 8

[0068] The preparation method of the photosensitive random copolymer is as follows: mix the hydroxyethyl methacrylate, cinnamoyl chloride, triethylamine, and dichloromethane of the above-mentioned component A in proportion, stir evenly, and react in an ice-water bath for 24 hours. The product was sequentially washed with deionized water, saturated K 2 CO 3 solution and deionized water, distill the extract under reduced pressure below 40°C, add absolute ethanol to dissolve, recrystallize, and vacuum d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com