Applicator head, hand-held applicator implement, applicator device and method for manufacturing solar or photovoltaic modules

A technology of coating equipment and applicators, used in the manufacture of house facades, greenhouses or inner wall vitrification, greenhouses, roofs, and the manufacture of solar or photovoltaic modules, which can solve problems such as bonding or sealing in aesthetic quality defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

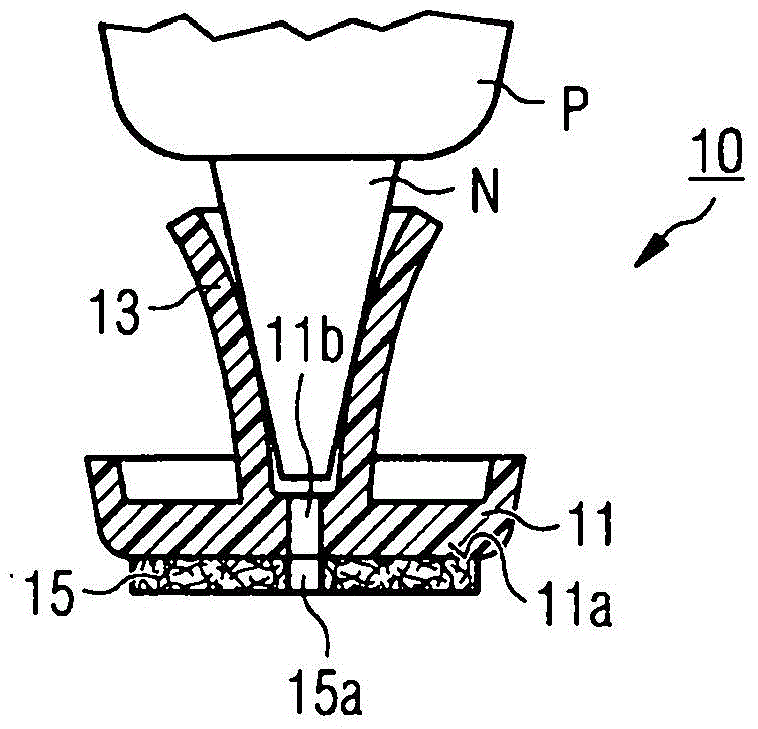

[0021] figure 1 An applicator head 10 is schematically shown, placed on a discharge nozzle N of a paste discharge device P, as is usually used for discharging adhesive or sealing materials. The applicator head 10 is approximately punch-shaped and has a base section 11 and a flared cone section 13 rising from the base section. The discharge needle N is pressed into the expansion cone section to such an extent that the elastic return force of the plastic-shaped cone sections separated from each other by the slit holds the applicator head in a frictional fit on the discharge needle on N. The exposed surface 11 a of the bottom section 11 forms a flat sliding surface and is covered with a glued felt 15 . The base section 11 and the fleece 15 each have a central opening 11b or 15a which is substantially aligned with the longitudinal axis of the discharge needle N of the paste discharge device P in the mounted state of the applicator.

[0022] The adhesive or sealing material disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com