Food forming apparatus with a food feed member

A molding equipment and food technology, applied in food molding, food science, meat extrusion, etc., can solve problems such as difficult access, difficult inspection, and hygiene risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

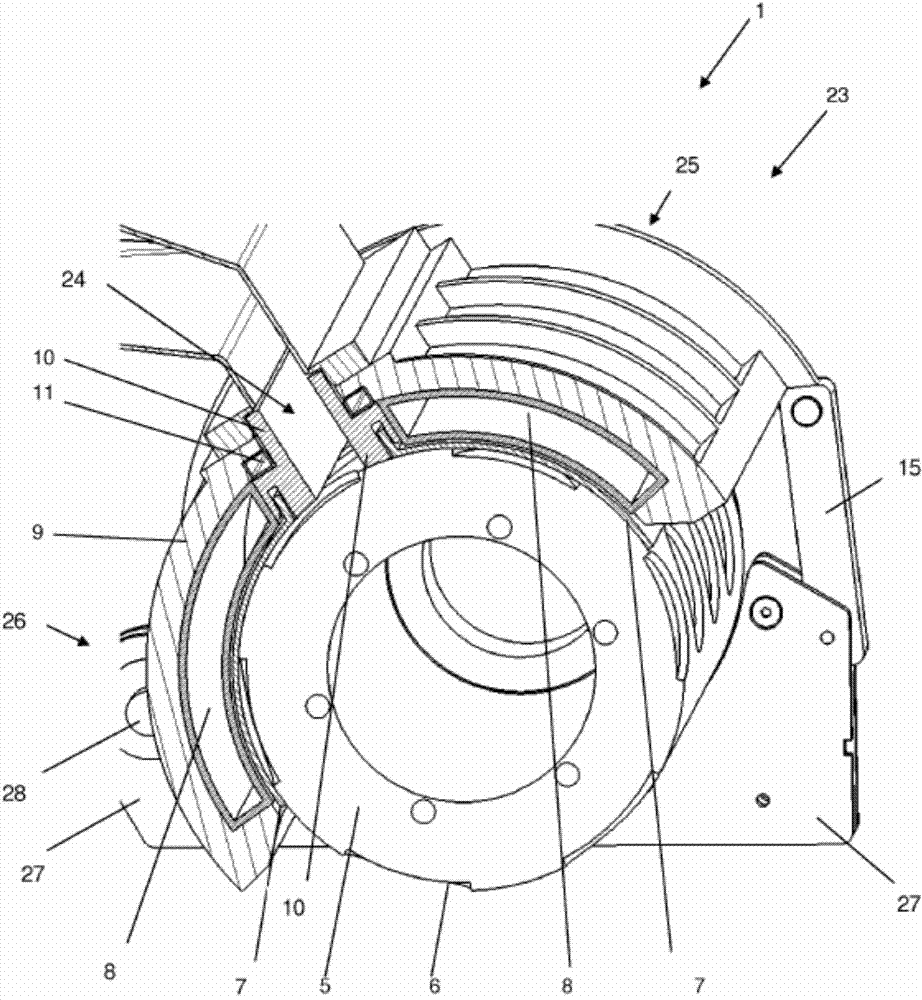

[0089] figure 1 A first embodiment of the invention is shown. The food forming device 1 comprises a drum 5 which in the present case turns counterclockwise and which is rotatably mounted on a frame 27 of the device 1 according to the invention. A plurality of product cavities 6 are provided on the outer circumference of the drum, which are filled with food mass to form the final food product. Around its circumference, the barrel comprises a number of equally spaced cavities, here six cavities. The drum further comprises a plurality of cavities arranged side by side in rows parallel to the axis of rotation of the drum. The cavities in each row are filled and emptied simultaneously. The device of the invention further comprises a bolus feeding member 23 , the housing 9 of which is mounted at one end by a hinge 28 on a frame 27 . The other opposite end is preferably also connected to the frame 27 via tie rods 15 . Preferably, the tie rod is adjustable to adjust the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com