Thin plate tensioning curved surface forming device

A curved surface forming and stretching technology, applied in the field of mechanical engineering, can solve the problems of horizontal wrinkling, no reduction in manufacturing cost, and cracking, and achieve the effects of saving energy, reducing forming force, and controlling horizontal wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

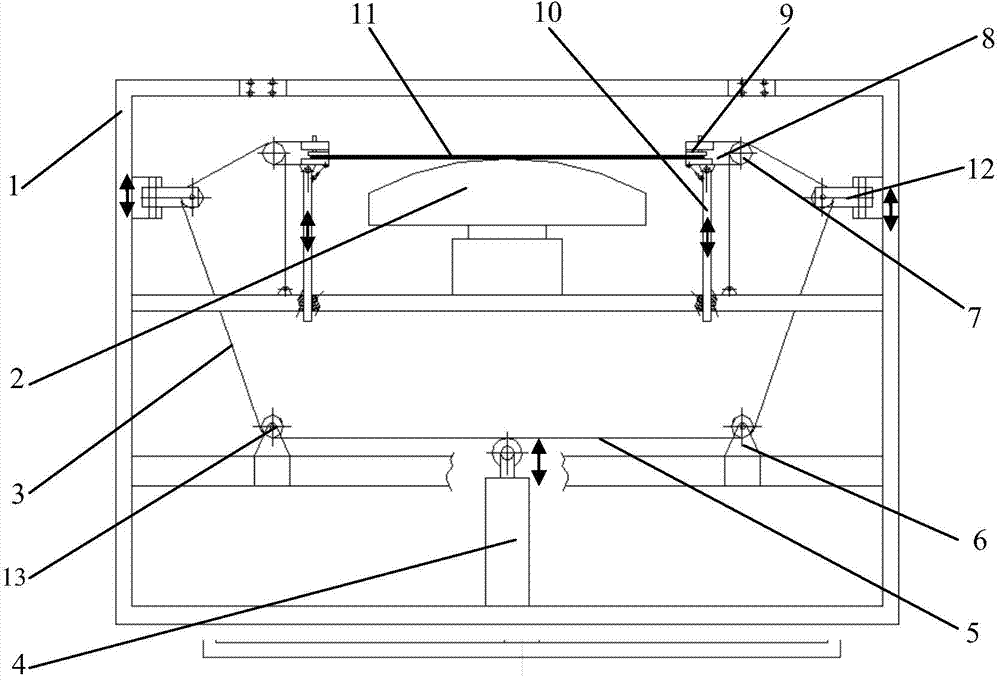

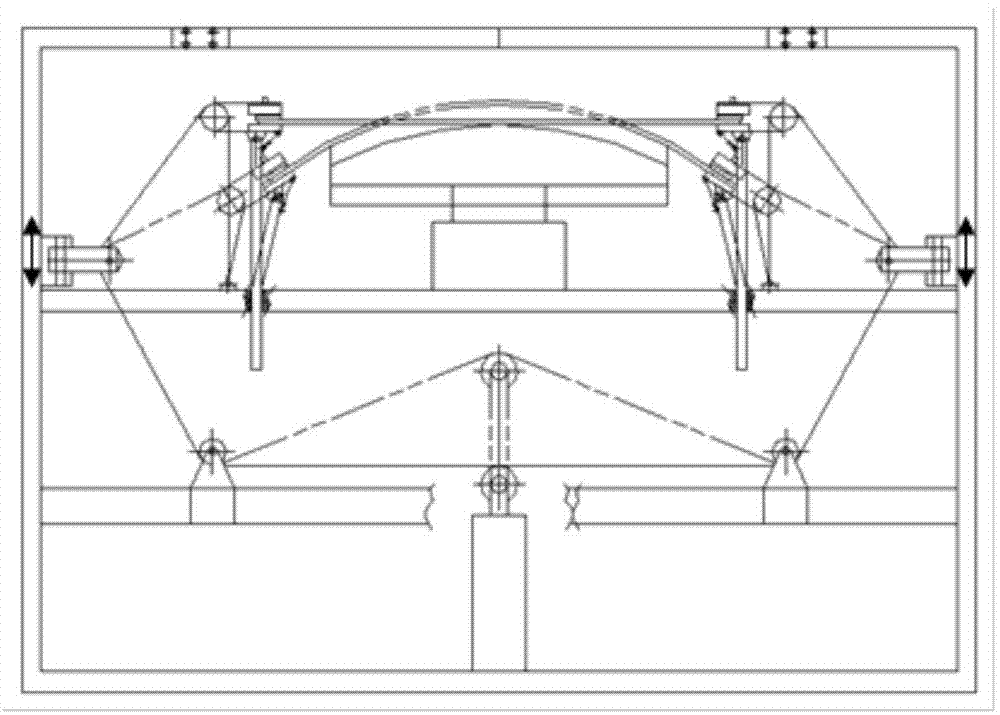

[0020] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0021] Specific implementation methods, such as figure 1 As shown, it is mainly composed of a frame 1, a mold lifting platform 2, a plate stretching system 3 distributed on both sides of the mold lifting platform 2, and a steel cable telescopic drive system 4.

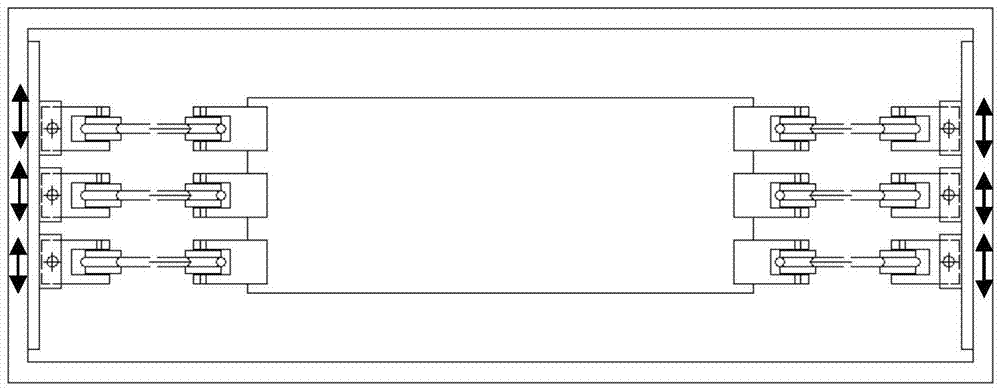

[0022] The number of each side of the two-sided plate stretching system 3 includes at least three, and each plate stretching system 3 includes a steel cable 5, a fixed pulley block 6, a movable pulley 7, and a plate clamping device 8. The steel The cable 5 changes direction through the fixed pulley block 6, and transmits force to the plate clamping device 8 through the movable pulley 7, and the movable pulley 7 and the plate clamping device 8 form an integral body.

[0023] One end of the steel cable 5 on one side of the plate stretching syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com