Servo-type heavy-load ultraprecise air bag supporting electric leveling system and leveling method thereof

An adjustment method and a heavy-duty technology, applied in the direction of control using feedback, etc., can solve problems such as high driving power, difficulty in fast and high-precision adjustment of support height, and difficulty in fast and high-precision adjustment of the leveling platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

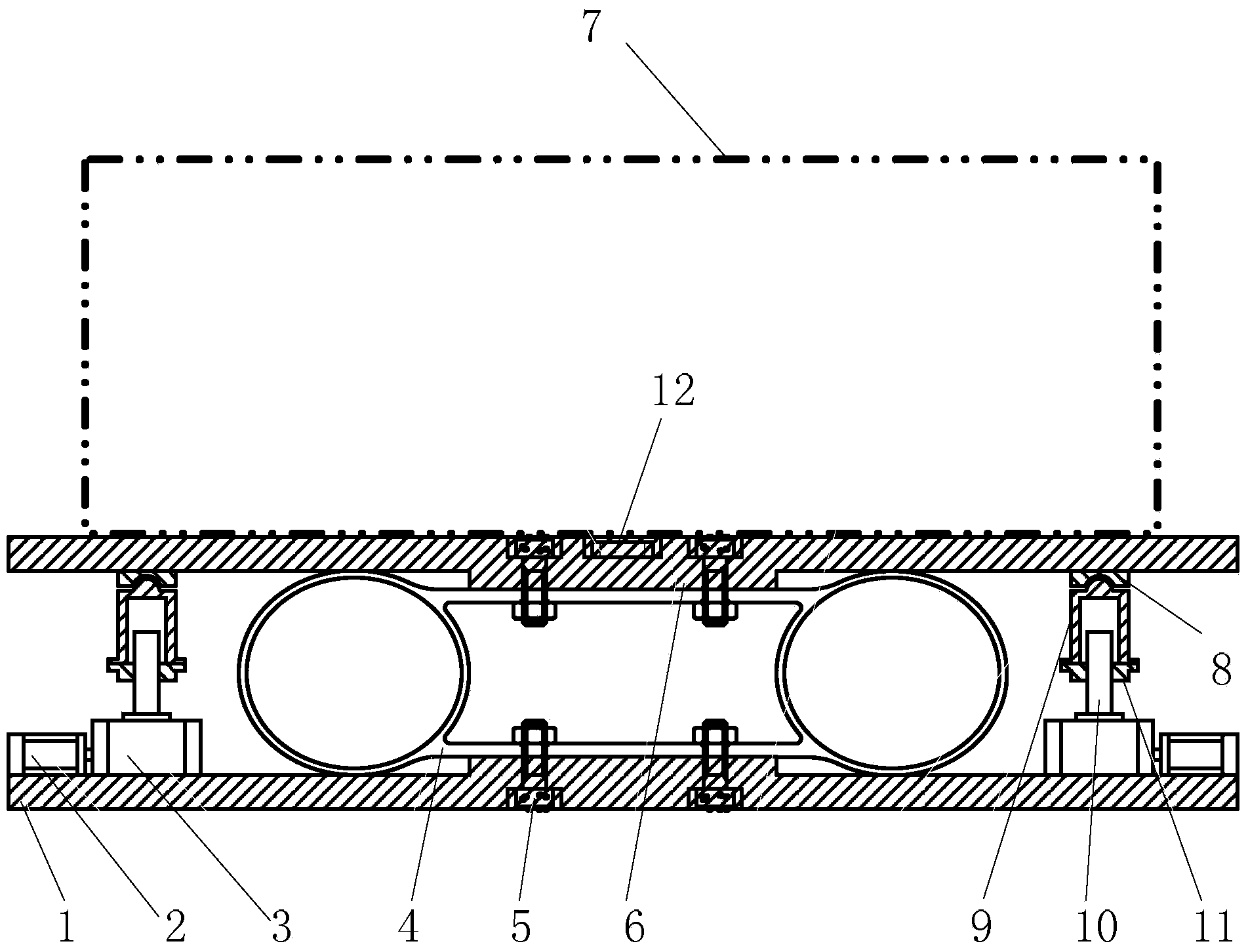

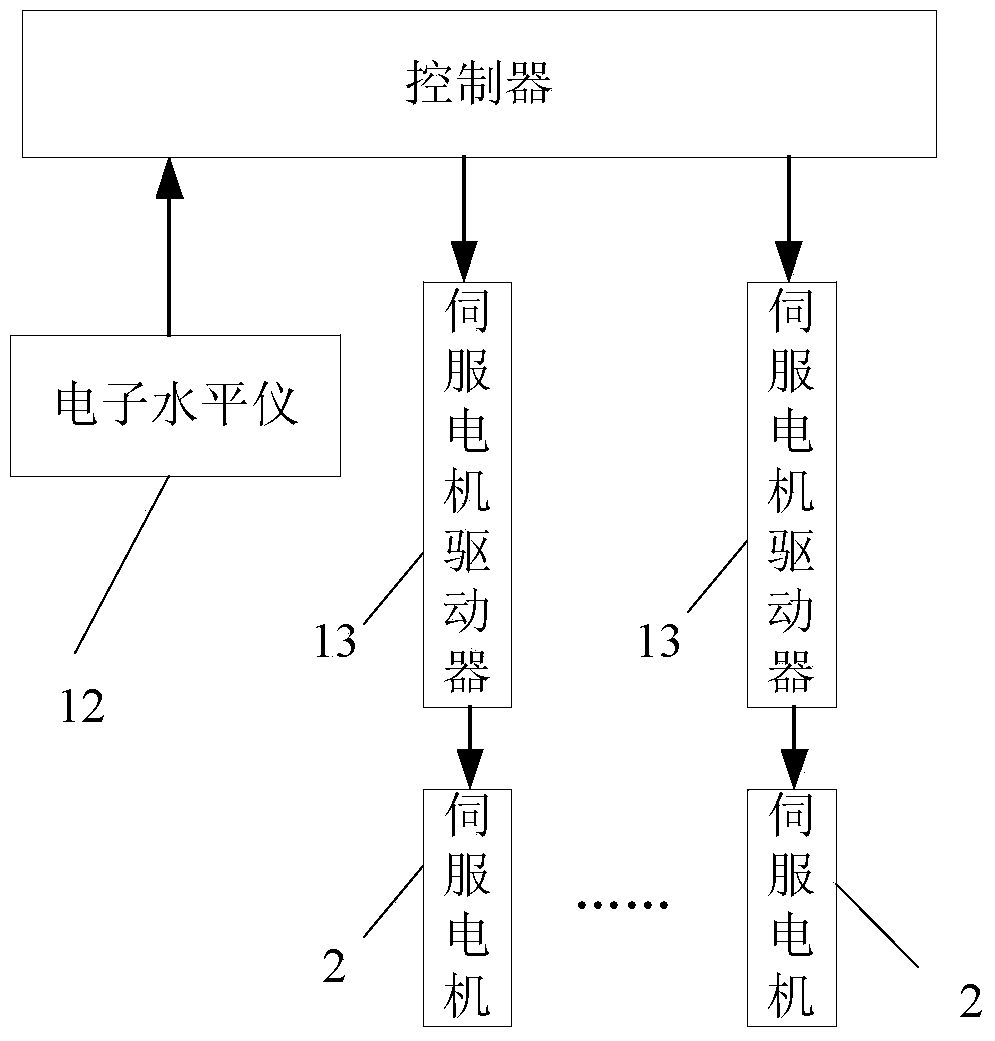

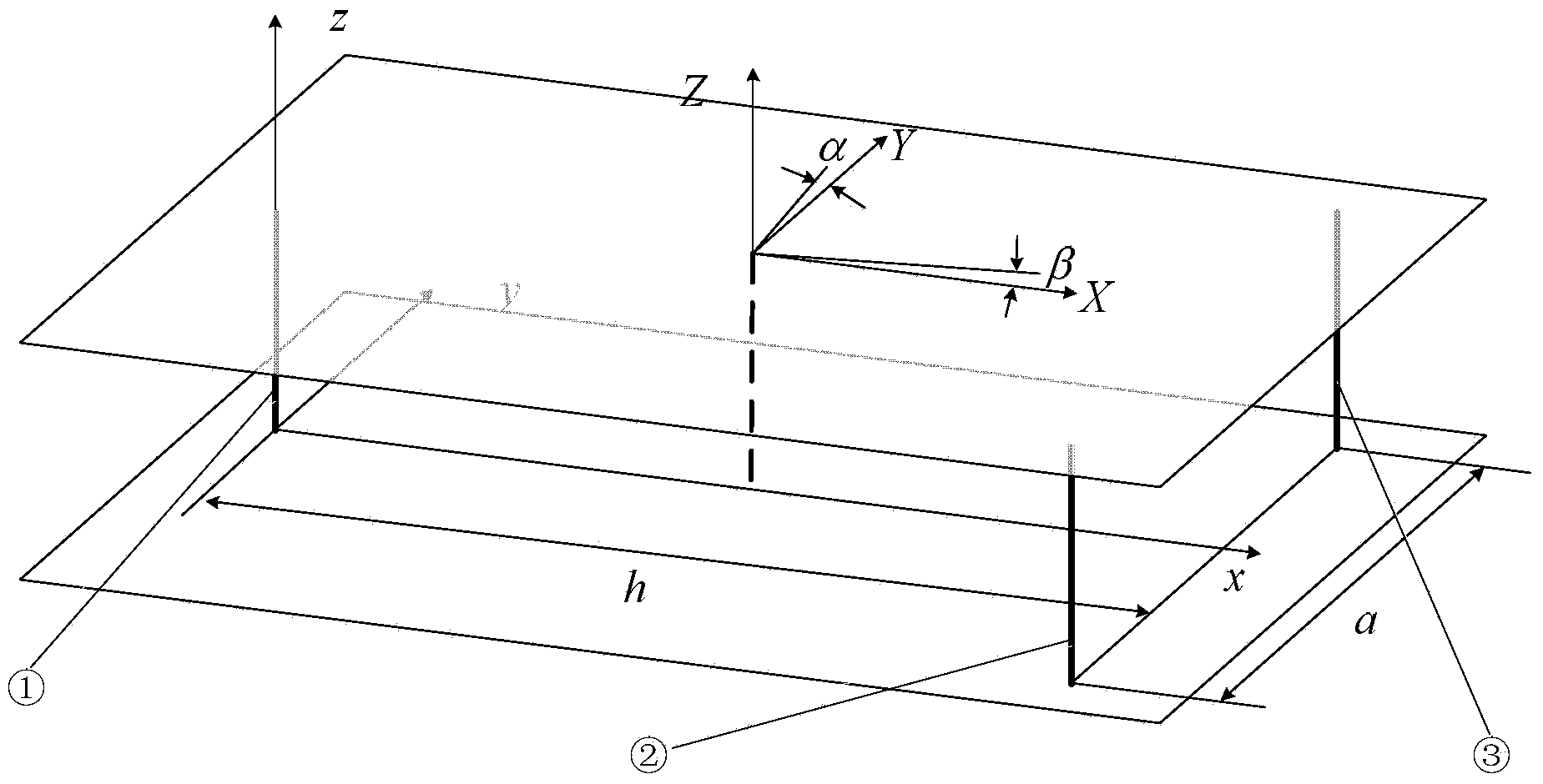

[0042] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, the servo-type heavy-duty ultra-precision airbag support electric leveling system described in this embodiment, the electric leveling system includes a base 1, a leveling platform 6, an airbag 4, and M groups of electric support height adjustment devices , an electronic level 12 and a controller; the value of M is an integer greater than 2;

[0043] The electronic level 12 is arranged on the upper surface of the leveling platform 6;

[0044] The lower surface of the leveling platform 6 contacts the top of the air bag 4, and the bottom of the air bag 4 is fixed on the base 1, and the position of the air bag 4 corresponds to the center of the base 1 and the leveling platform 6;

[0045] M sets of electric support height adjustment devices are arranged between the leveling platform 6 and the base 1, M sets of electric support height adjustment devices are equally spaced outside the...

specific Embodiment approach 2

[0054] Embodiment 2: This embodiment is a further limitation of the servo-type heavy-duty ultra-precision airbag supporting electric leveling system described in Embodiment 1. The servo height adjustment device includes a reducer 3, a ball screw 10, a wire Female 11, sleeve 9 and ball hinge 8;

[0055] The reducer 3 is fixed on the base 1, the power output end of the servo motor 2 is connected with the power input end of the reducer 3, the torque output end of the reducer 3 is connected with the torque input end of the ball screw 10, and the ball screw 10 is connected to one end of the sleeve 9 through a screw nut 11, and the other end of the sleeve 9 is connected to the ball joint 8, and the ball joint 8 is fixed on the lower surface of the leveling platform 6.

[0056] In this embodiment, the airbag 4 is used as the main support to bear most of the weight (90% or higher) of the leveling platform 6 and the load 7, and the electric support height adjustment device bears the re...

specific Embodiment approach 3

[0057] Embodiment 3: This embodiment is a further limitation of the servo-type heavy-duty ultra-precision airbag supporting electric leveling system described in Embodiment 1 or 2. The value of M is 3, 4 or 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com