Amplitude modulation double-end grain counting machine

A technology of head count and pellet machine, applied in the field of pellet machine, can solve the problems of multiple pellets, poor feeding of capsules, sticking to the counting board or sticking to the wall of the feeding funnel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

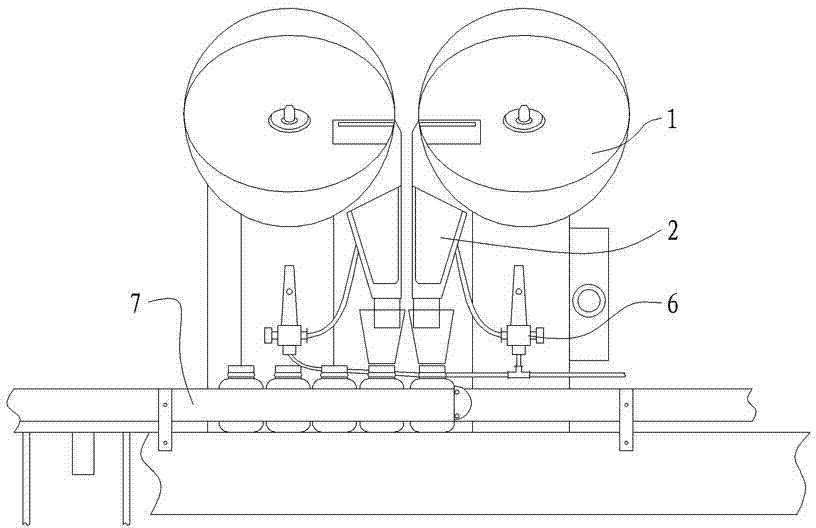

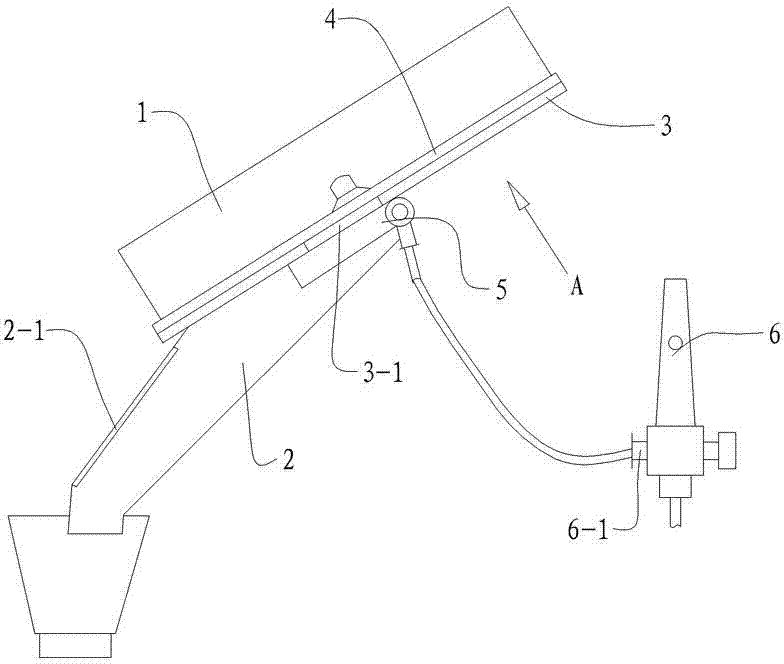

[0014] The amplitude modulation double-head counting machine of the present embodiment, such as figure 1 , figure 2 and image 3 As shown, it includes an upper hopper 1 and a lower capsule funnel 2 located below the upper hopper 1 and communicated with the upper hopper. A fixed plate 3 is provided at the connection between the upper hopper 1 and the lower capsule funnel 2 . The top of the fixed disk 3 is provided with a counting disk 4, and the bottom of the fixed disk 3 is fixed with an air pipe 5.

[0015] The air pipe 5 is connected to a gas flowmeter 6 through a two-way valve 5-1, the gas flowmeter 6 is connected to an air compressor, and the outlet of the gas flowmeter 6 is provided with an air flow regulating valve 6-1. The airflow adjusting valve 6-1 can adopt screw-in bolts and the like.

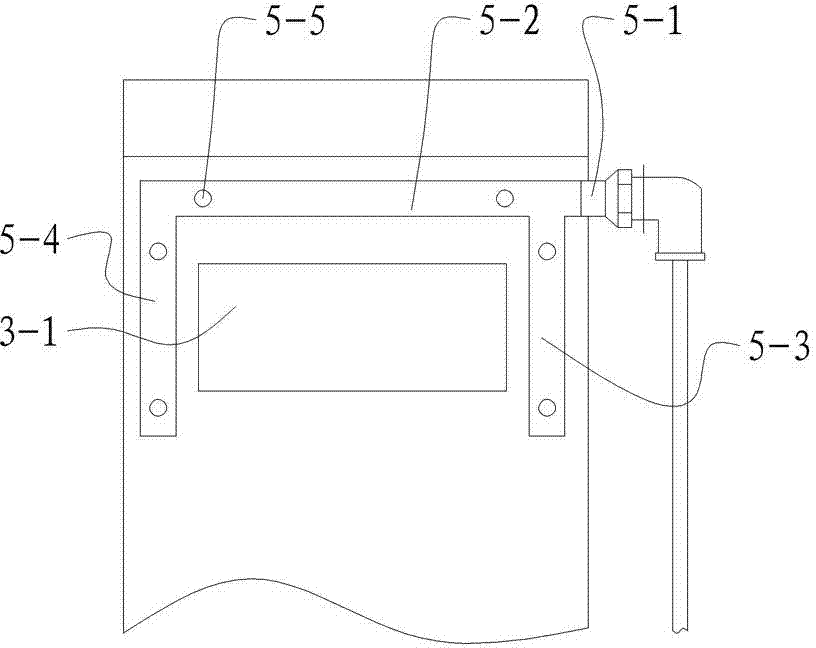

[0016] The fixed disc 3 is shaped on a rectangular blanking opening 3-1. The air pipe 5 includes a first air pipe 5-2, a second air pipe 5-3 and a third air pipe 5-4 which comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com