Spin anchoring pipe

A technology of anchor grouting and anchor pipe, which is applied in the installation of anchor bolts, mining equipment, earthwork drilling and mining, etc. It can solve the problems of unsatisfactory roadway surrounding rock control, difficulty in roadway surrounding rock control and maintenance, poor stability of roadway surrounding rock, etc. Problems, to achieve the effect of adjustable curing time, improve the effect of axial and radial constraints, and improve the reliability of anchoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

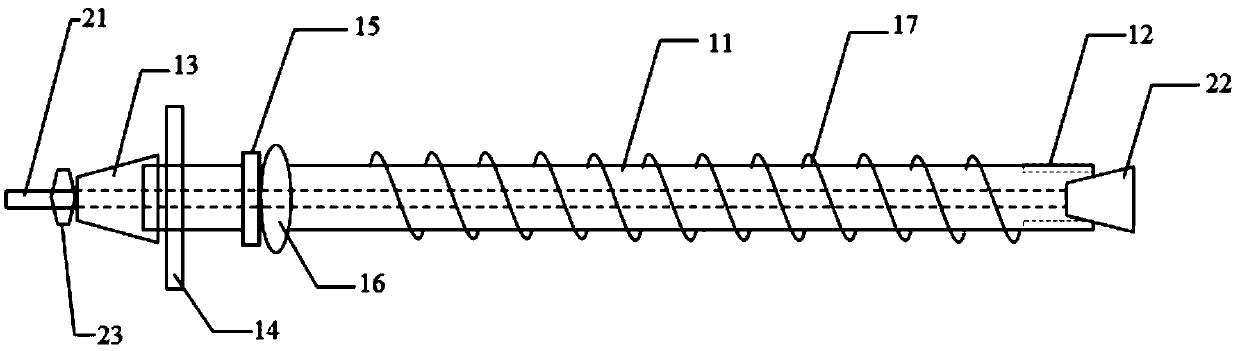

[0034] The spin anchor injection pipe is characterized in that it includes an anchor pipe body and an internal injection tensioning set; the anchor pipe body includes a steel pipe 11, and one end of the steel pipe 11 is provided with a longitudinal crack 12, and the other end is provided with a reducing sleeve 13, A tray 14, a retaining ring 15, a rubber stopper 16 and an anchor screw 17 are sequentially arranged between the reducing sleeve 13 and the longitudinal crack 12, and the retaining ring 15 is welded on the steel pipe 11 and the distance between the reducing sleeve 13200~ 400mm, the rubber stopper 16 is close to the retaining ring 15, the anchor screw 17 is welded on the steel pipe 11 body; One end of the internal injection tensioning pipe 21 close to the longitudinal crack 12 is welded with a vertebral body 22 , and the other end is provided with a primary anchor nut 23 outside the reducing sleeve 13 .

Embodiment 2

[0036] The spin anchor injection pipe is characterized in that it includes an anchor pipe body and an internal injection tensioning set; the anchor pipe body includes a steel pipe 11, and two longitudinal cracks 12 are evenly arranged at one end of the steel pipe 11, and a variable diameter sleeve is provided at the other end 13. A tray 14, a retaining ring 15, a rubber stopper 16 and an anchor screw 17 are sequentially arranged between the reducing sleeve 13 and the longitudinal crack 12. The retaining ring 15 is welded on the steel pipe 11 and the distance between the reducing sleeve 13200mm, the rubber stopper 16 is close to the retaining ring 15, the anchor screw 17 is welded on the steel pipe 11; Pipe 21 , the inner injection tension pipe 21 is welded with a vertebral body 22 at one end close to the longitudinal crack 12 , and the other end is provided with a primary anchor nut 23 outside the reducing sleeve 13 .

Embodiment 3

[0038] The spin anchor injection pipe is characterized in that it includes an anchor pipe body and an internal injection tensioning set; the anchor pipe body includes a steel pipe 11, and three longitudinal cracks 12 are evenly arranged at one end of the steel pipe 11, and a variable diameter sleeve is provided at the other end 13. A tray 14, a retaining ring 15, a rubber stopper 16 and an anchor screw 17 are sequentially arranged between the reducing sleeve 13 and the longitudinal crack 12. The retaining ring 15 is welded on the steel pipe 11 and the distance between the reducing sleeve 13300mm, the rubber stopper 16 is close to the retaining ring 15, the anchor screw 17 is welded on the steel pipe 11; Pipe 21 , the inner injection tension pipe 21 is welded with a vertebral body 22 at one end close to the longitudinal crack 12 , and the other end is provided with a primary anchor nut 23 outside the reducing sleeve 13 . The outer diameter of the retaining ring 15 is φ40.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com