Spinal crest elastic internal fixation device

An internal fixator and fixator technology, applied in the direction of internal fixator, fixator, internal bone synthesis, etc., can solve the problems of spinous process fracture, insufficient fixation force of implant, spinous process cutting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

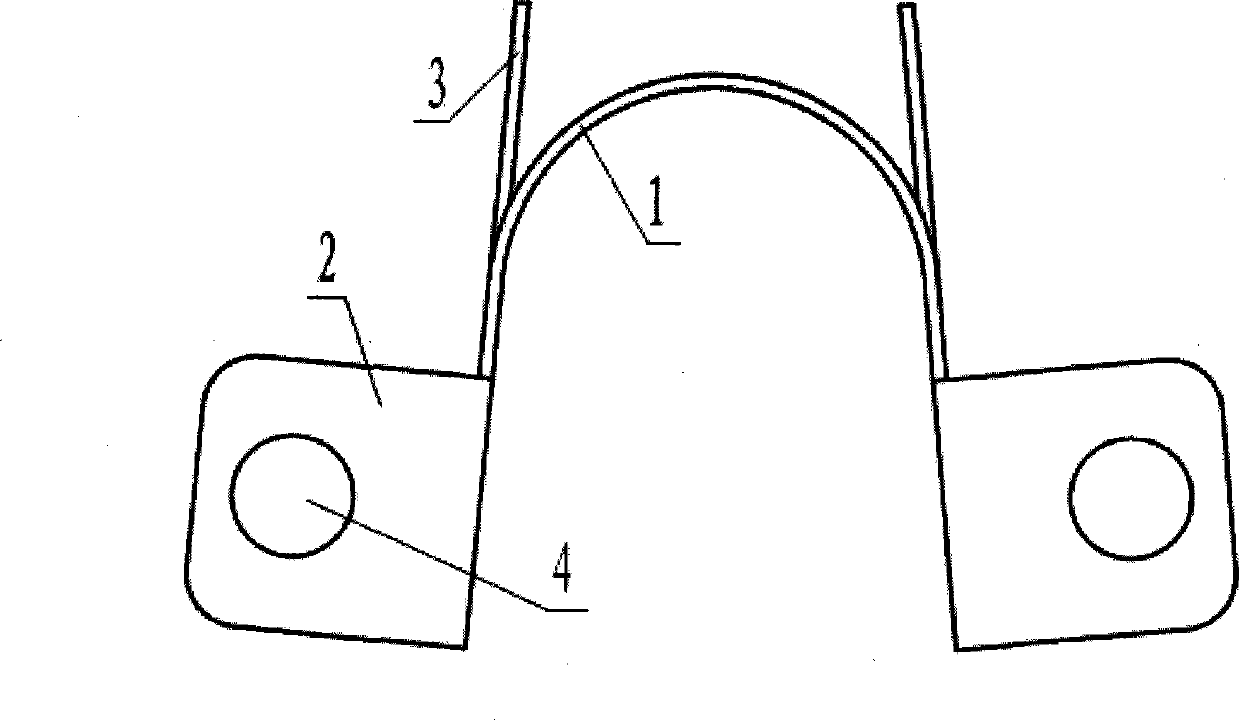

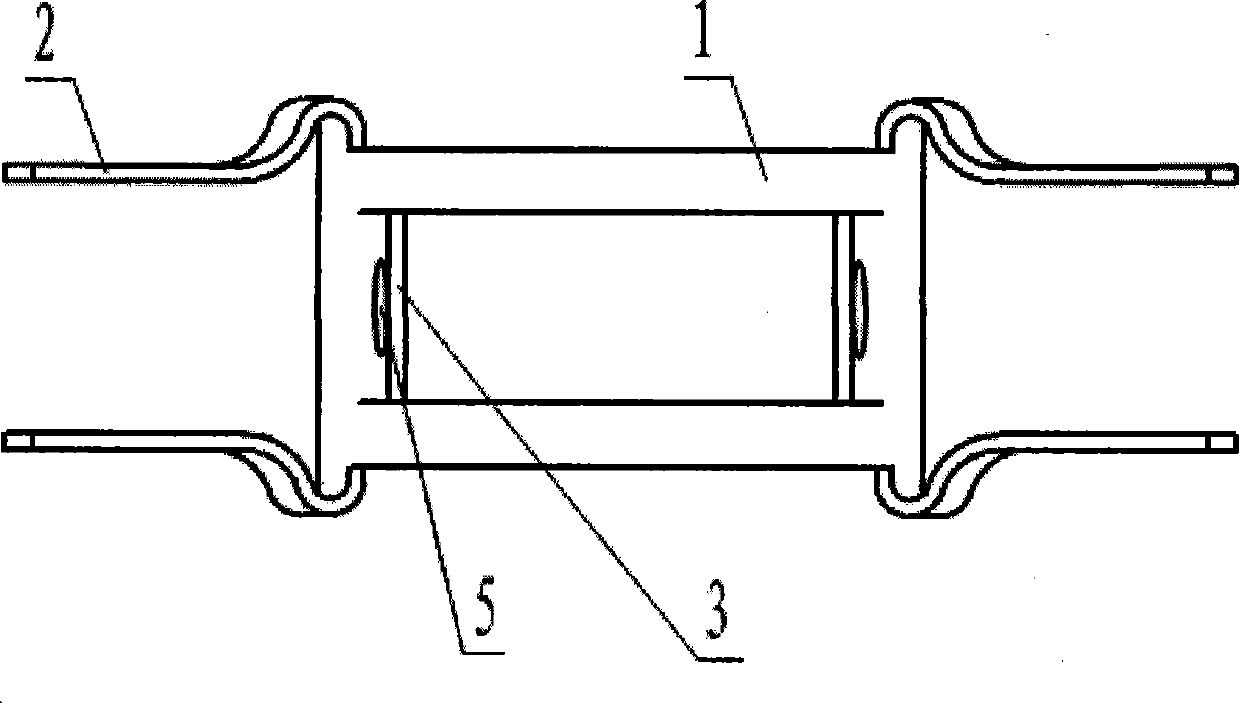

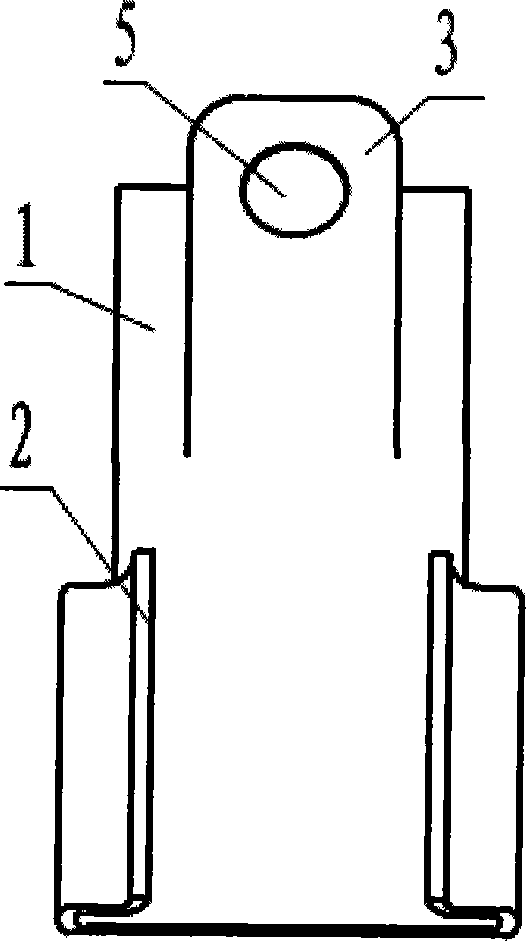

[0017] see Figures 1 to 3 , the U-shaped elastic sheet 1 and the two U-shaped cards 2 and the wings 3 on both sides are composed of Figure 4 Shown is stamped from sheet of titanium alloy. see Figure 4 , the elastic sheet 1 is formed by bending the part A in the figure, the two U-shaped cards 2 are formed by folding the B parts at both ends relative to each other, and the two side wings 3 are formed by hollowing out the C part and then turning up relatively. In order to avoid the spinous process fracture caused by external force directly acting on the spinous process, the root connected with the U-shaped clip 2 and the U-shaped elastic sheet 1 is bent into an outwardly arched arc (see figure 2 and image 3 ). see Figures 1 to 3 and combine Figure 4 , The bolt holes 4 on the two U-shaped cards 2 and the self-tapping screw holes 5 on the two wings 3 can be punched together when punching, or can be processed separately after punching.

[0018] according to Figures 1 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com