Four-pipeline dual-head granule counting machine

A four-pipe, head-count technology, applied in the direction of solid materials, packaging, packaging item types, etc., can solve problems affecting product quality, capsule cutting, multi-grain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

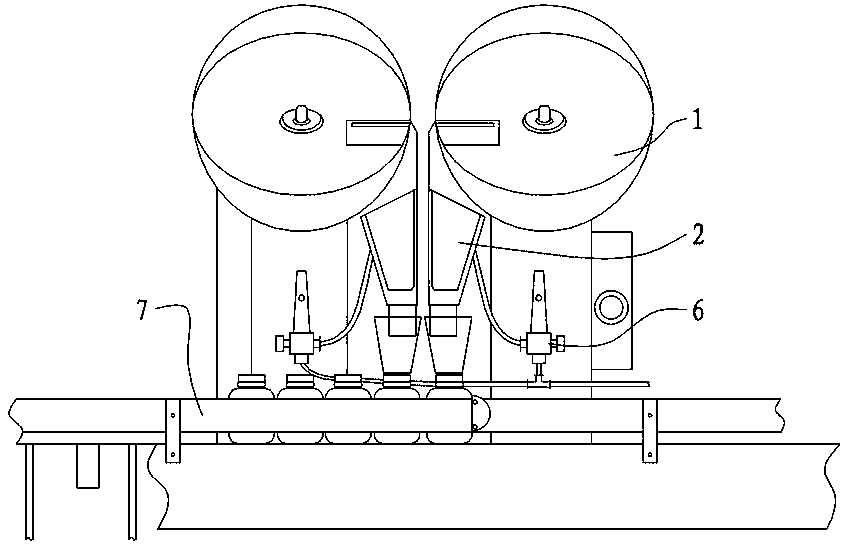

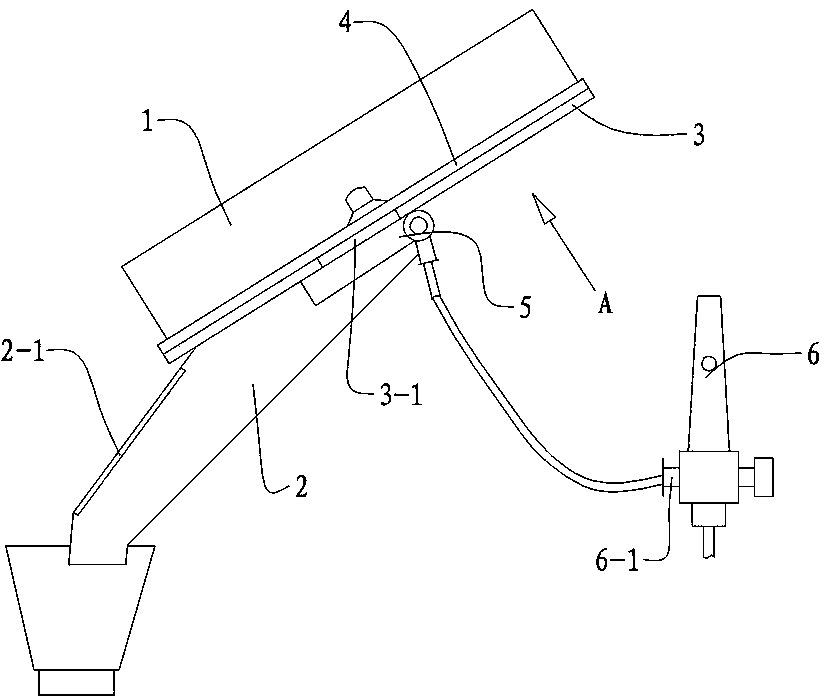

[0014] The four-pipeline double-head counting machine of the present embodiment, such as figure 1 , figure 2 and image 3 As shown, it includes an upper hopper 1 and a lower capsule funnel 2 located below the upper hopper 1 and communicated with the upper hopper. A fixed plate 3 is provided at the connection between the upper hopper 1 and the lower capsule funnel 2 . The top of the fixed disk 3 is provided with a counting disk 4, and the bottom of the fixed disk 3 is fixed with an air pipe 5.

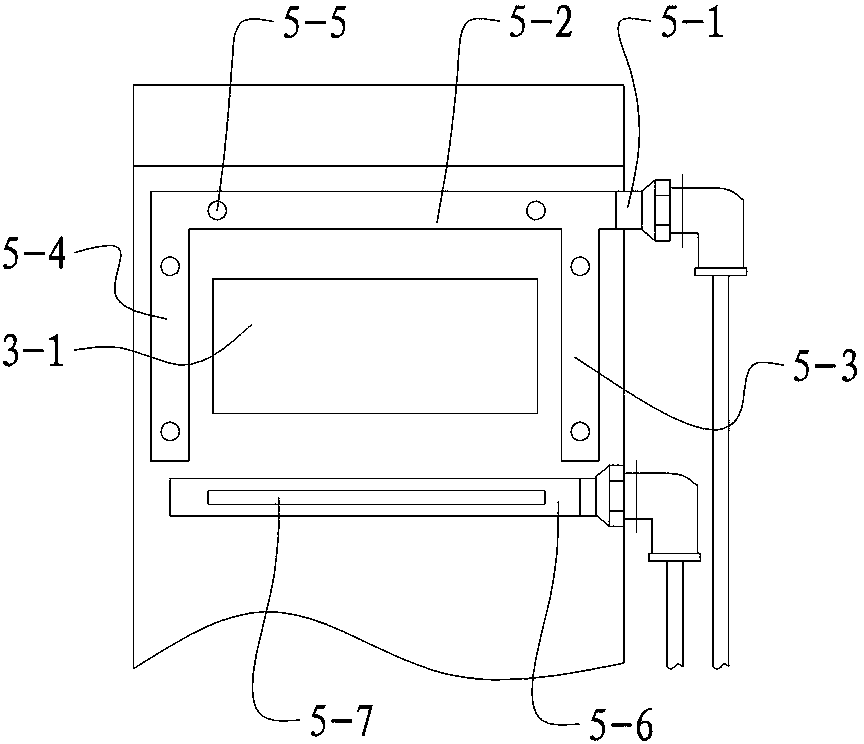

[0015] The air pipe 5 is connected to a gas flowmeter 6 through a two-way valve 5-1, the gas flowmeter 6 is connected to an air compressor, and the outlet of the gas flowmeter 6 is provided with an air flow regulating valve 6-1. The airflow adjusting valve 6-1 can adopt screw-in bolts and the like.

[0016] The fixed disc 3 is shaped on a rectangular blanking opening 3-1. The air pipe 5 includes a first air pipe 5-2, a second air pipe 5-3 and a third air pipe 5-4 which communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com