Internal gear machine

A technology of gear machines and gears, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., and can solve problems such as the balance pressure is not constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

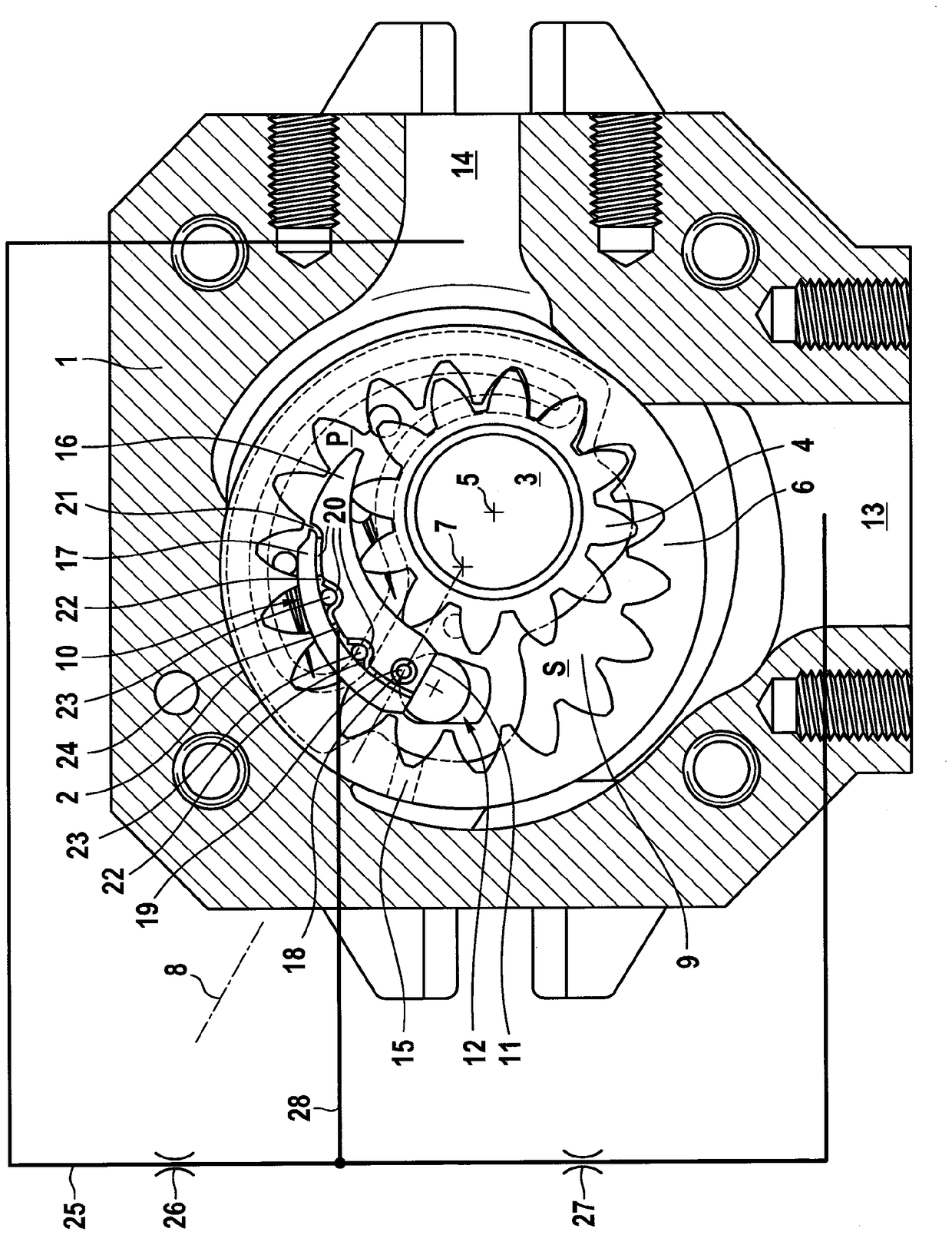

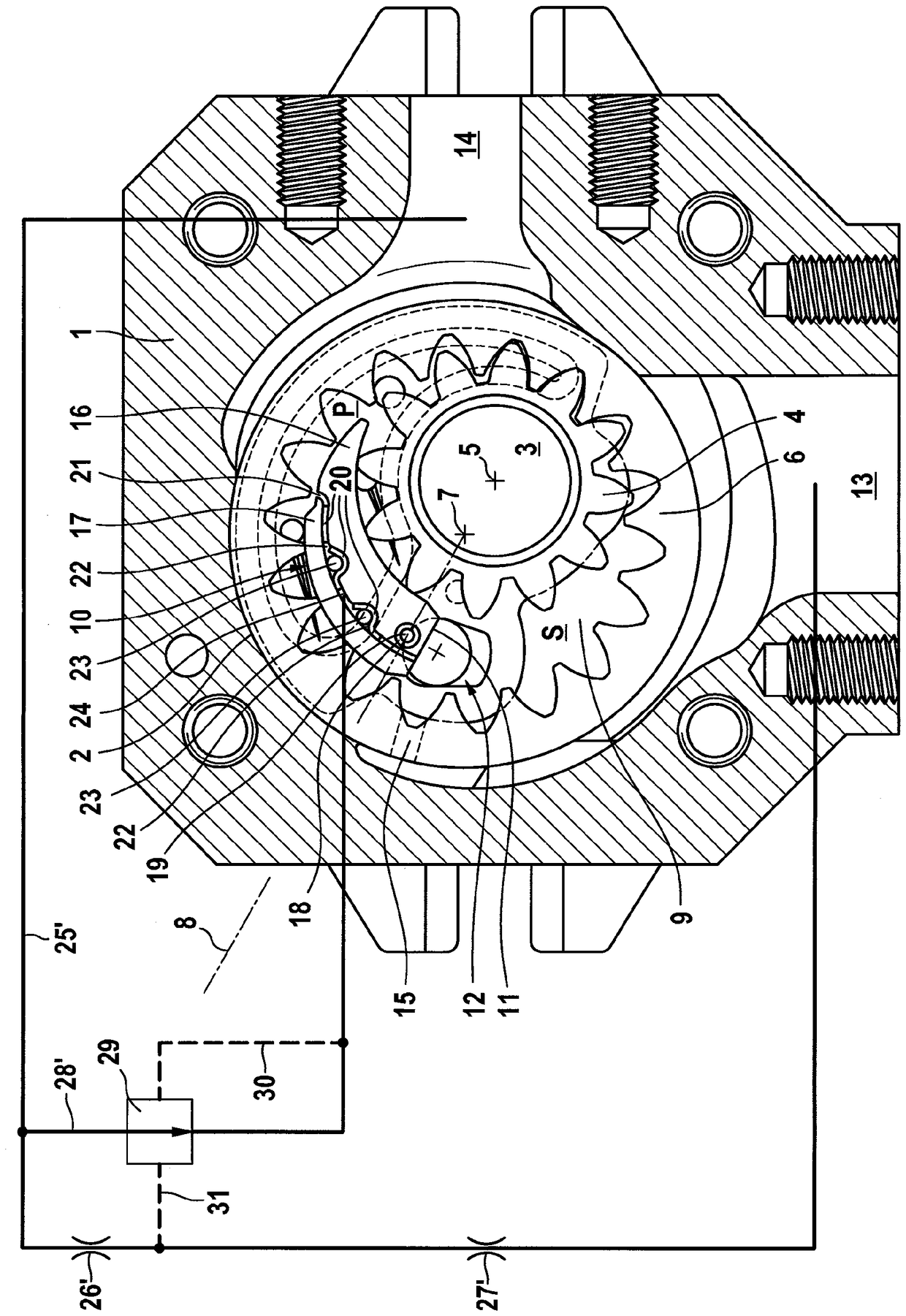

[0014] in figure 1 The internal gear machine shown in has a housing, and an annular middle part 1 of the housing can be seen. The middle part 1 encloses a pump chamber 2 which is closed by two unshown side parts of the housing. In the two side parts, a drive shaft 3 is rotatably supported. On the drive shaft 3, an externally toothed pinion 4 is arranged in the pump chamber 2 in a non-rotatable manner. The gear axis 5 and the longitudinal axis of the drive shaft 3 fall together.

[0015] The ring gear of the pinion 4 has twelve teeth. The pinion gear is surrounded by a hollow gear 6 provided with eighteen internal teeth, the gear axis 7 of which extends parallel to and eccentric to the gear axis 5 of the pinion gear. A central plane 8 extends through the gear axes 5 and 7.

[0016] The ring gear 6 is rotatably supported in the corresponding circular pump chamber 2 of the middle part with its radially surrounding cylindrical shell surface. In the regions on both sides of the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com