A triangular crawler type mobile mechanism

A technology of triangular crawler and moving mechanism, which is applied to crawler vehicles, motor vehicles, transportation and packaging, etc., can solve problems such as incompatibility in complex and harsh terrain, and achieve improved reliability and passability, low transmission noise, and improved sand and soil removal. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

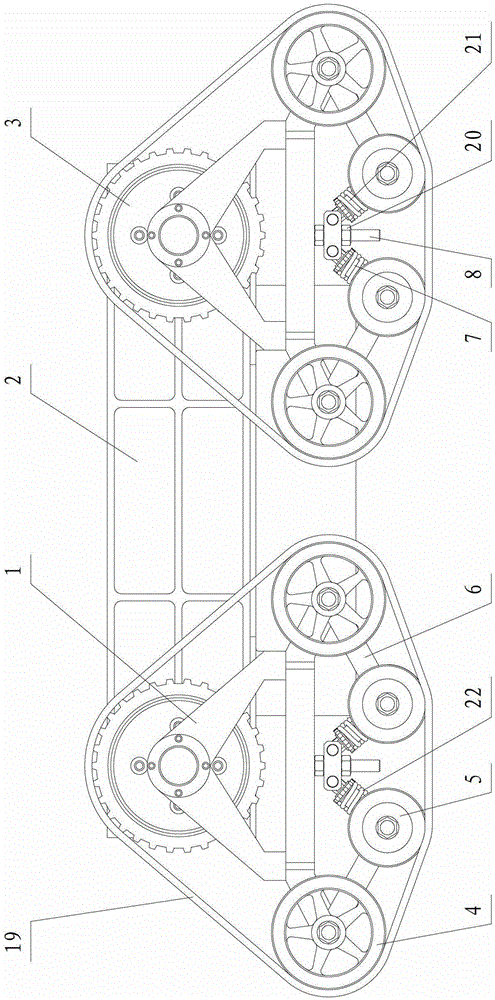

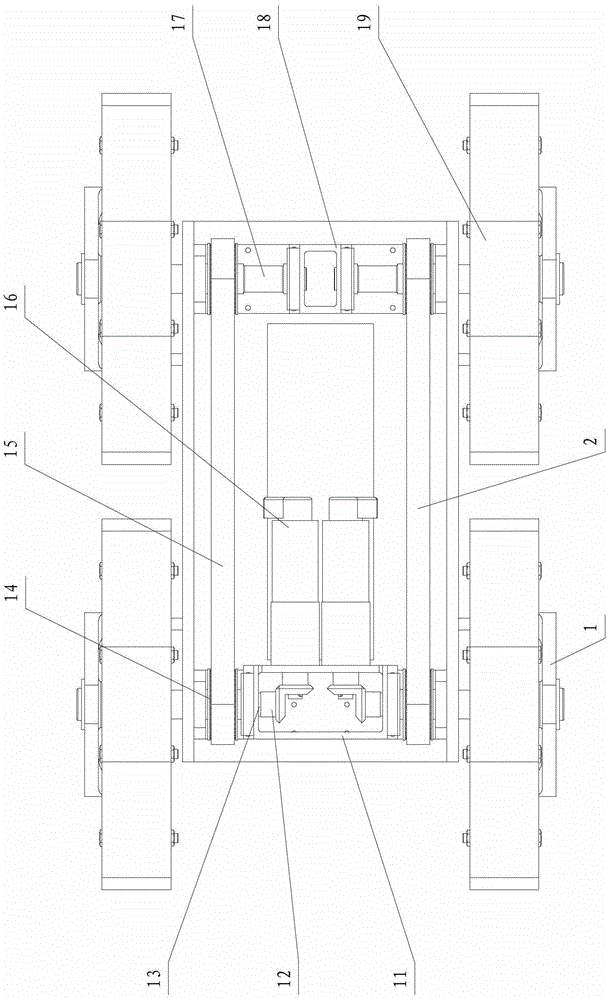

[0021] The present invention comprises a chassis box 2, a drive motor 16 and a triangular track assembly, wherein a plurality of triangular track assemblies are symmetrically arranged on the left and right sides of the chassis box 2, and each side of the triangular track assembly has an independent drive motor 16 , the triangular crawler belt assemblies on the left and right sides are respectively connected with the driving motor 16 installed in the chassis box 2 through the transmission device; as image 3 As shown, the present embodiment has four triangular track assemblies, and each side of the chassis box 2 is respectively provided with two, which are symmetrical in pairs.

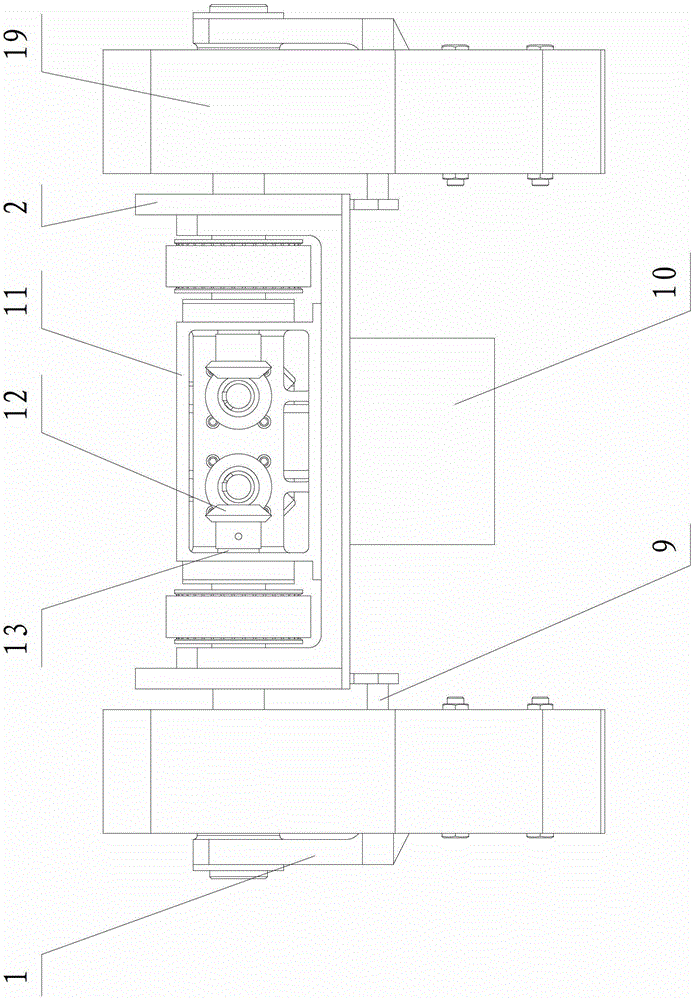

[0022] The front and rear ends in the chassis box 2 are respectively provided with a motor bracket 11 and a drive shaft bracket 18, which improves the rigidity of the chassis box 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com