A device and method for shearing rock structural planes

A structural surface and rock technology, applied in the field of rock structural surface shearing devices, can solve problems not related to the development of rock shear testing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

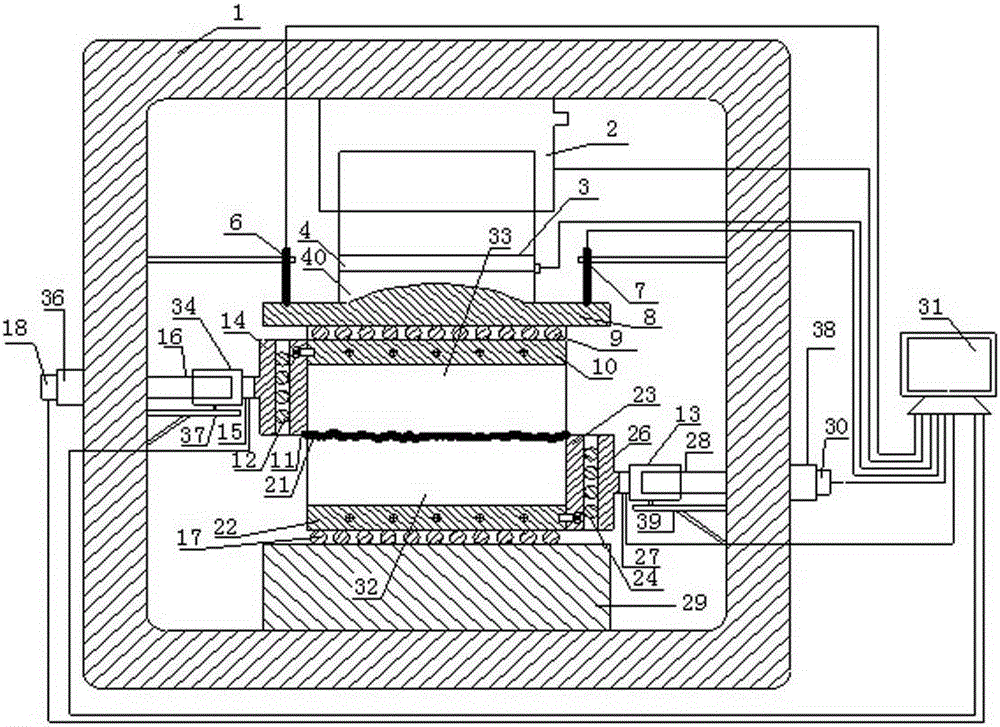

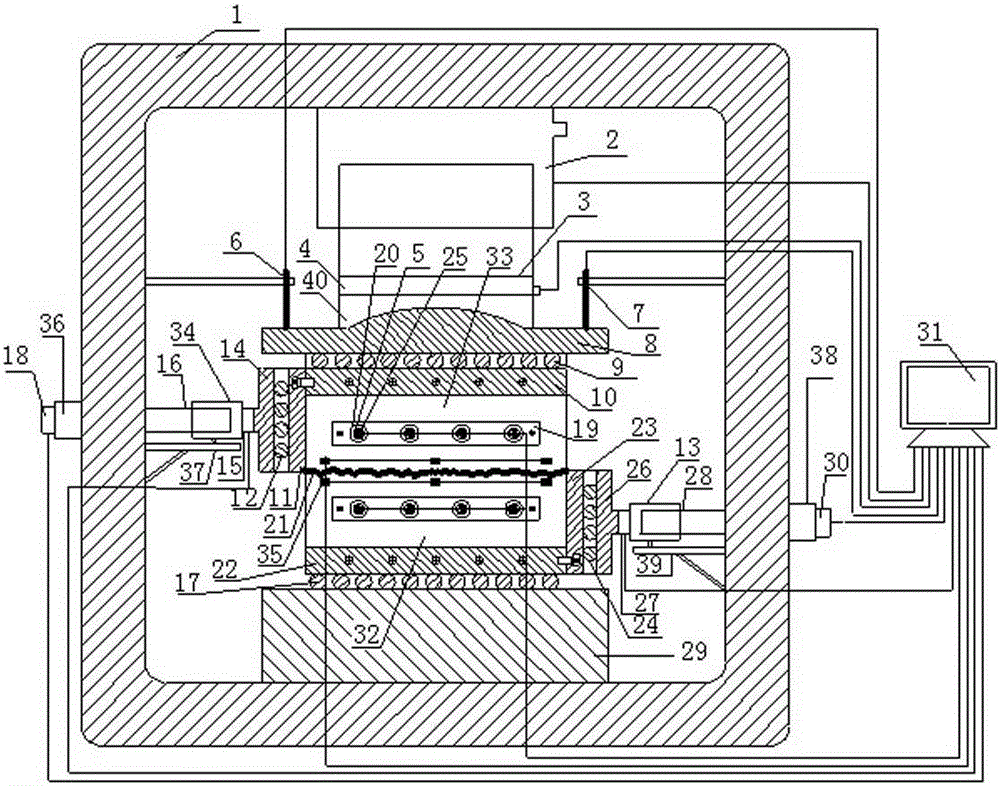

Embodiment 1

[0038] The shearing method of the rock structure plane of the present invention comprises the following steps:

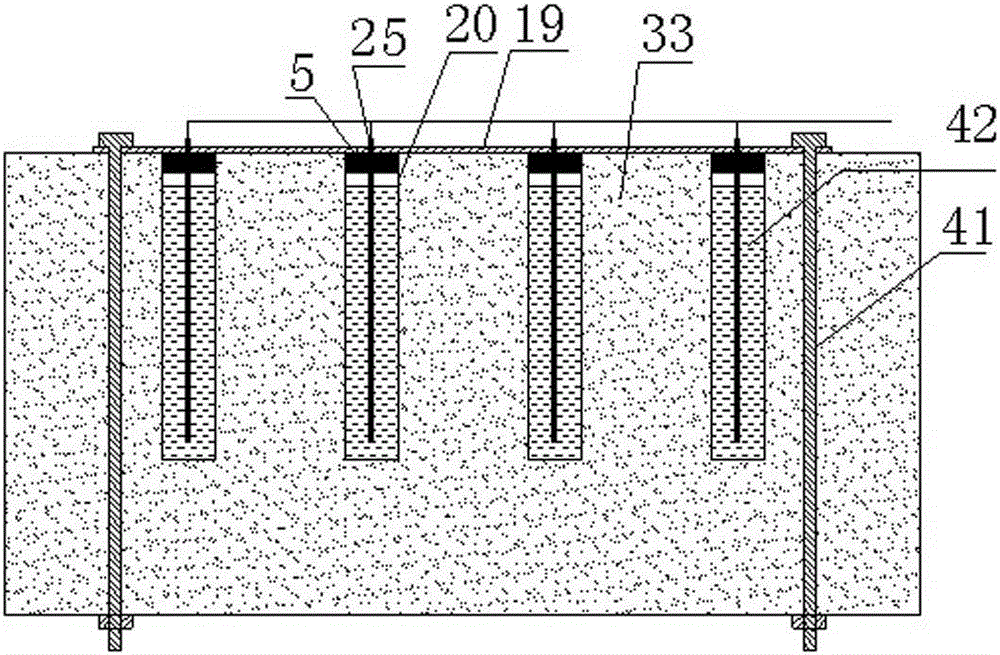

[0039] (1) Fabrication and heating of test pieces: Maokou limestone hanging wall rock blocks and footwall rock blocks including rock structural planes were selected at the mine roadway engineering site. The rock blocks on the Maokou limestone rock structure surface and the footwall rock blocks are all cut into: length * width * height = 20cm * 10cm * 15cm test piece, on the rock structure face of Maokou limestone rock block 33, Four heating holes 20 are respectively processed on the rock block 32 of the footwall, and the depth is 2 / 3 of the thickness of the rock block sample, and then high-quality high-temperature resistant silicone oil 42 is injected into it, and the rubber plug 5 with a heating rod 25 is used to seal and heat the hole. Hole 20, glue and seal the rubber plug 5 and heating hole 20 with high temperature resistant glue, and tightly block the heating h...

Embodiment 2

[0045] This example adopts basically the same implementation method as Example 1, the difference is: step (1) heat the temperature of the high-quality heat-resistant silicone oil on the rock structure surface of Maokou limestone and in the heating hole of the footwall rock block to 100 °C, after heating for 5 hours, the average temperature value of the upper and lower rock blocks is 94.5 °C obtained by temperature sensors at various places on the upper wall rock block and footwall rock block of the rock structure.

[0046] The peak shear strength of the structural plane of Maokou limestone obtained under the above treatment conditions is 5.71±1.10MPa, and the peak dilation displacement is 1.03±0.27mm

Embodiment 3

[0048] This example adopts the same implementation method as Example 1, the difference is: step (1) heat the temperature of the high-quality heat-resistant silicone oil on the rock structure surface of Maokou limestone and in the heating hole of the footwall rock block to 150 °C, after heating for 5 hours, the average temperature value of the upper and lower rock blocks is 138.3°C obtained by temperature sensors at various places on the upper wall rock block and footwall rock block of the rock structure.

[0049] The peak shear strength of the structural plane of Maokou limestone obtained by the above treatment conditions is 3.89±0.95MPa, and the peak dilation displacement is 1.36±0.35mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com