Valve, energy conversion device/fluid distribution network including valve and method of disassembling valve

A fluid distribution and network technology, applied to mechanical equipment, cocks including cut-off devices, valve details, etc., can solve problems such as personnel danger, journal eccentricity, obturator eccentricity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

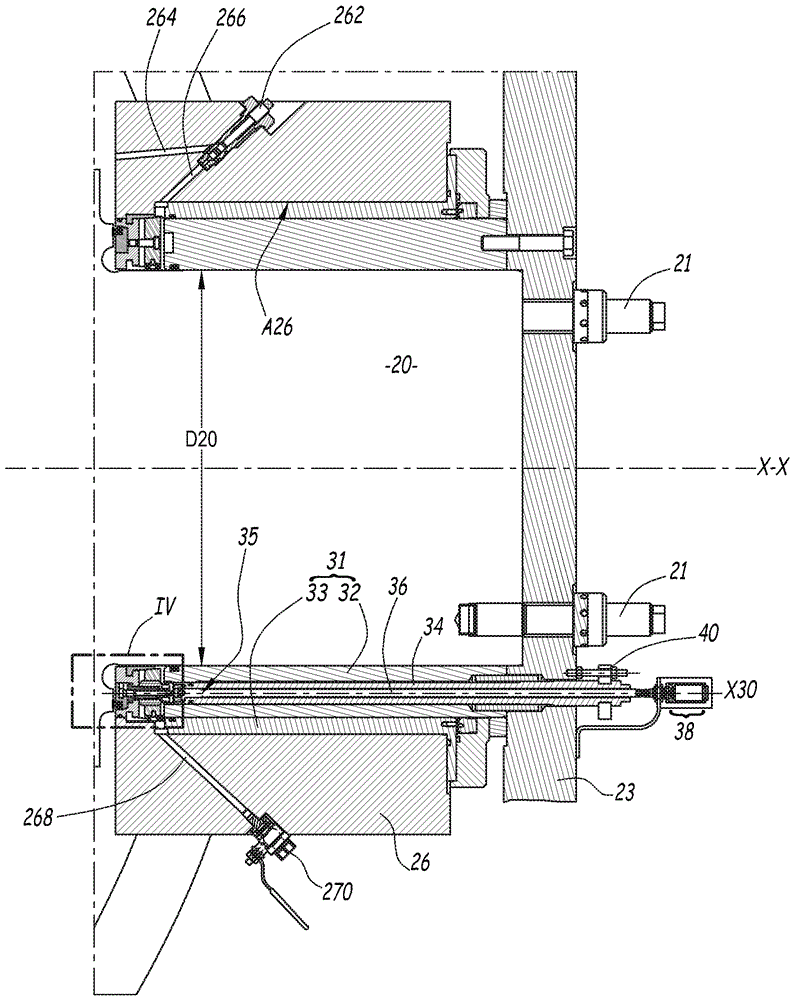

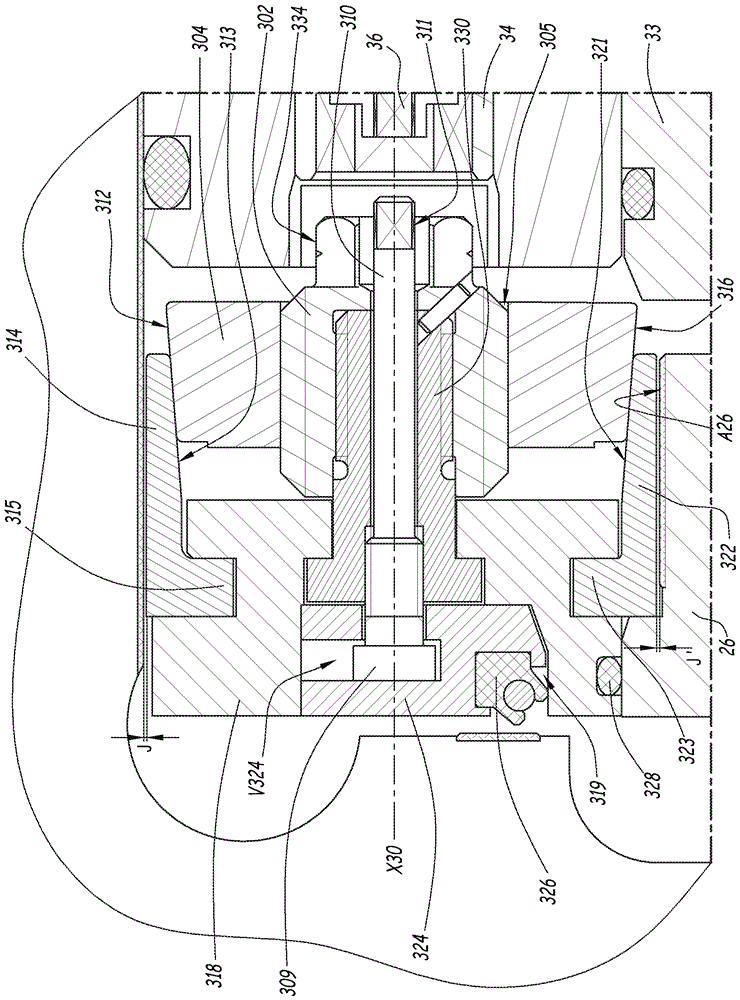

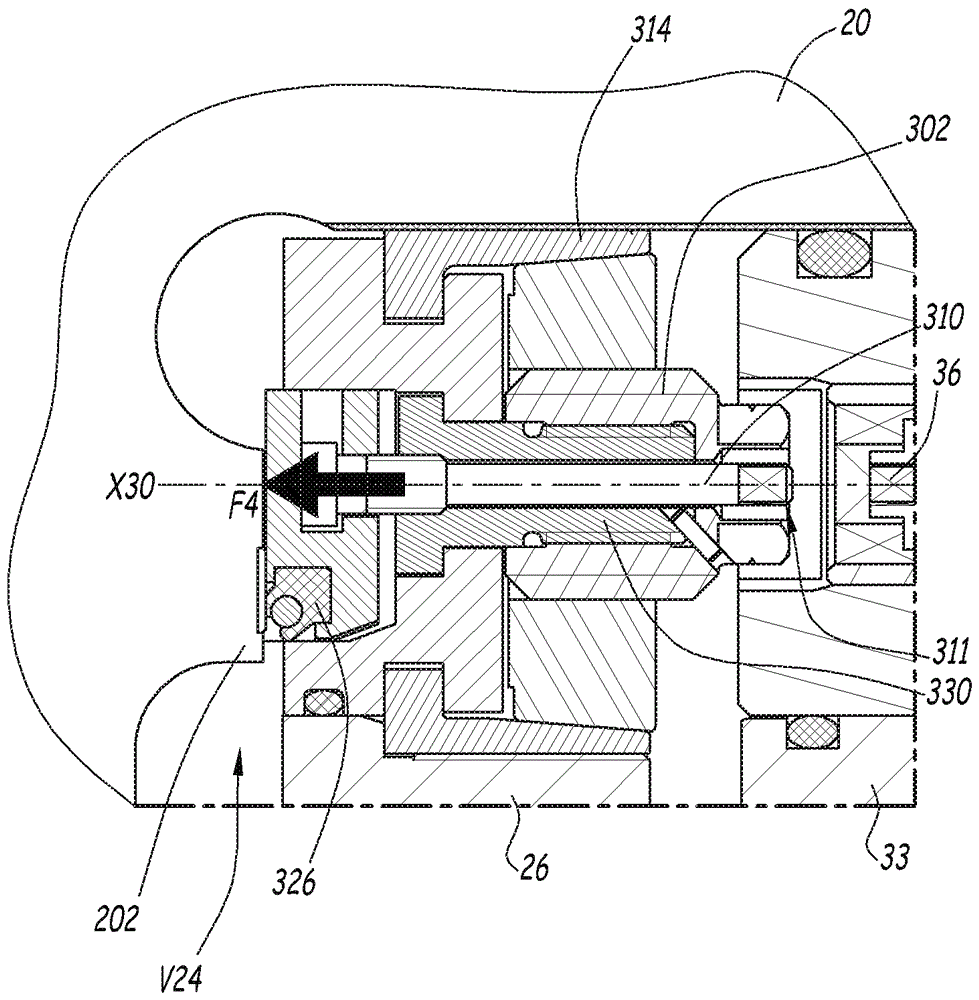

[0034] exist figure 1 An example of a device 1 for converting hydraulic energy into electrical energy according to the present invention is shown in , comprising a dam B, an upstream tank R1, a plurality of hydraulic machines M1 and M2, and a downstream tank R2. Among other things, this type of hydraulic equipment offers a simple way of storing electrical energy: during the day, each hydraulic machine acts as a turbine, i.e. uses the hydraulic energy caused by the height difference between the upstream holder R1 and the hydraulic machines M1 or M2, e.g. The alternator is rotated and thus generates electricity, and at night acts as a pump, supplying the water contained in the downstream retainer R2 to the upstream retainer R1. For this purpose, the hydraulic device also comprises a supply pipe C connected to the upstream holder R1 , which allows all hydraulic machines to be fed in parallel by means of a bifurcation D located on the upstream side of all hydraulic machines. Two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com