Water tank drain valve with water leakage detection function

A drainage valve and water level detection technology, which is applied to flushing equipment with water tanks, water supply devices, buildings, etc., can solve problems such as difficulty in finding detection and solutions, large amount of wasted water, and drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

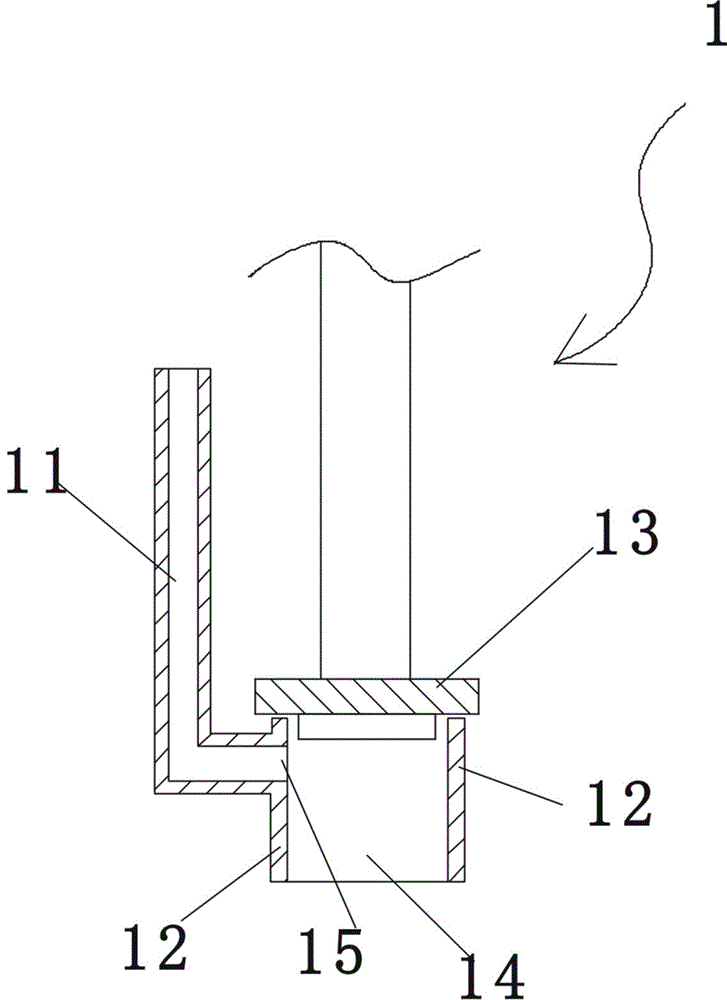

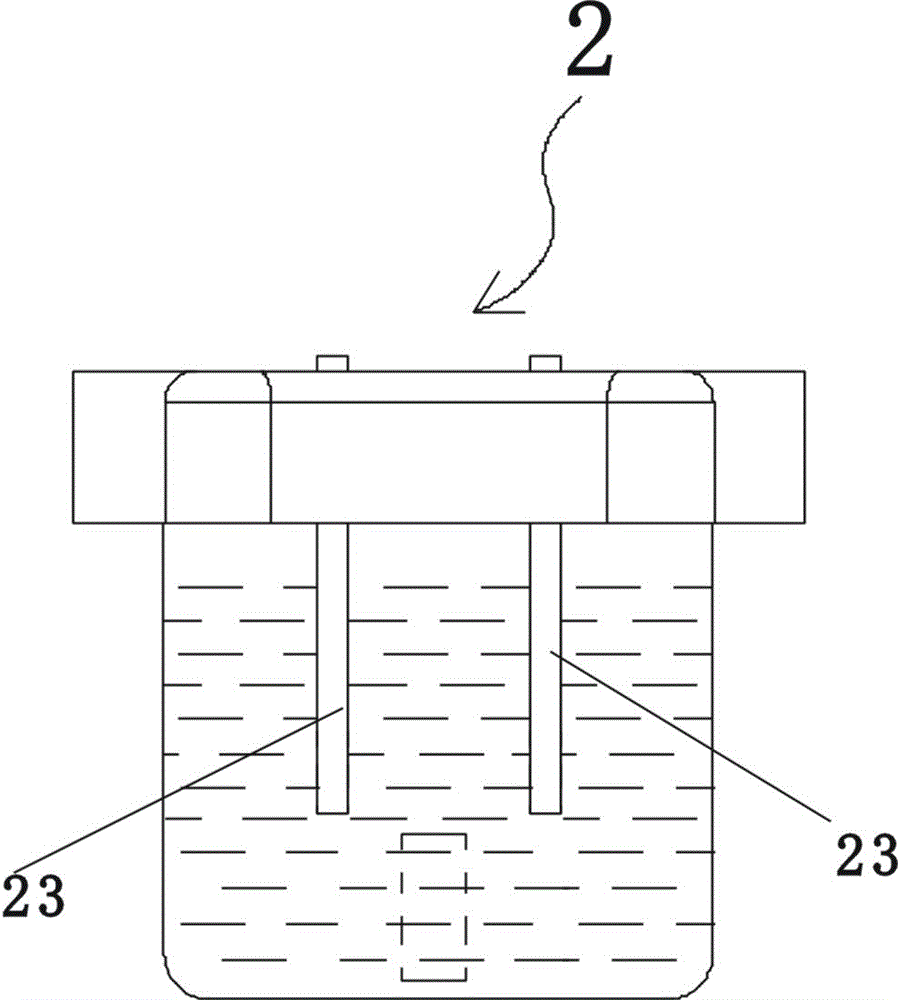

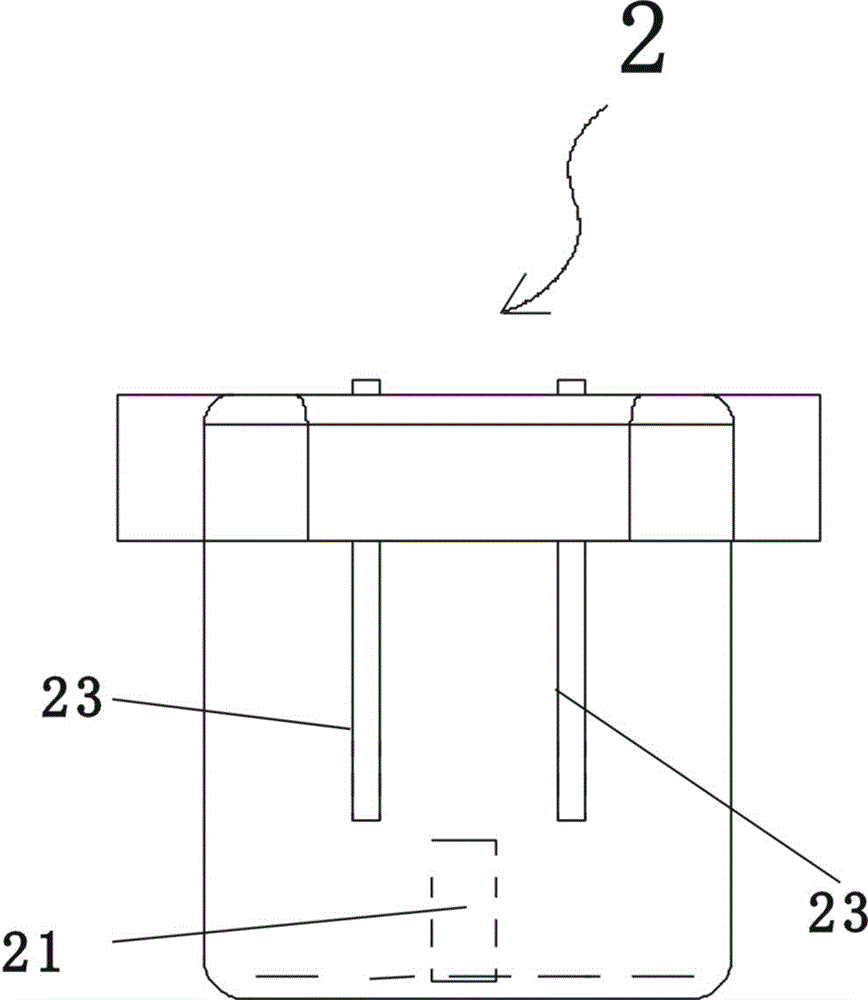

[0037] Figure 7 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , image 3 , figure 2 As shown, the water tank drain valve with water leakage detection function in this embodiment includes a valve body 1, the valve body is provided with an overflow pipe 11, an annular base 12, a valve cover 13, and a valve cover control for controlling the opening or closing of the valve cover. Mechanism, the bonnet control mechanism is the same as the traditional technology, the center of the ring-shaped base 12 forms a drain 14, and the valve cover 13 is movable to cover the top of the drain 14 of the ring-shaped base; the ring-shaped base 12 is provided with an overflow hole 15. The lower end of the overflow pipe 11 communicates with the overflow hole 15; a water storage cylinder 2 and a water guide groove 4 are arranged in the drain outlet 14, and the horizontal projection shape of the water guide groove 4 is arc-shaped, and the water guide groove 4 is close to the ring shape T...

Embodiment 2

[0051] In this embodiment, the horizontal projection shape of the water guide groove is circular, the water guide groove is close to the inner surface of the circular base, and the vertical position of the water guide groove is lower than the vertical position of the overflow hole, and the water guide groove is provided with Align the notch on the water inlet of the water storage cylinder. In this way, no matter the valve cover is not tightly closed and the water leaks, or the water inlet channel leaks, the water flow will continuously flow into the water guide groove, and continue to flow into the water inlet of the water storage tank through the gap of the water guide groove, and finally the inner cavity of the water storage tank will continue to accumulate water. In addition, in the second embodiment, only the lowest point of one metal contact is higher than the lowest point of the small water discharge hole of the water storage cylinder, and the lowest point of the other me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com